Attachable mailer

a mailer and attachment technology, applied in the field of mailers, can solve the problems of limiting the size of the envelope, time-consuming assembly, and the inability of the sender to meet the requirements of the envelope, and achieve the effect of simple and time-efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

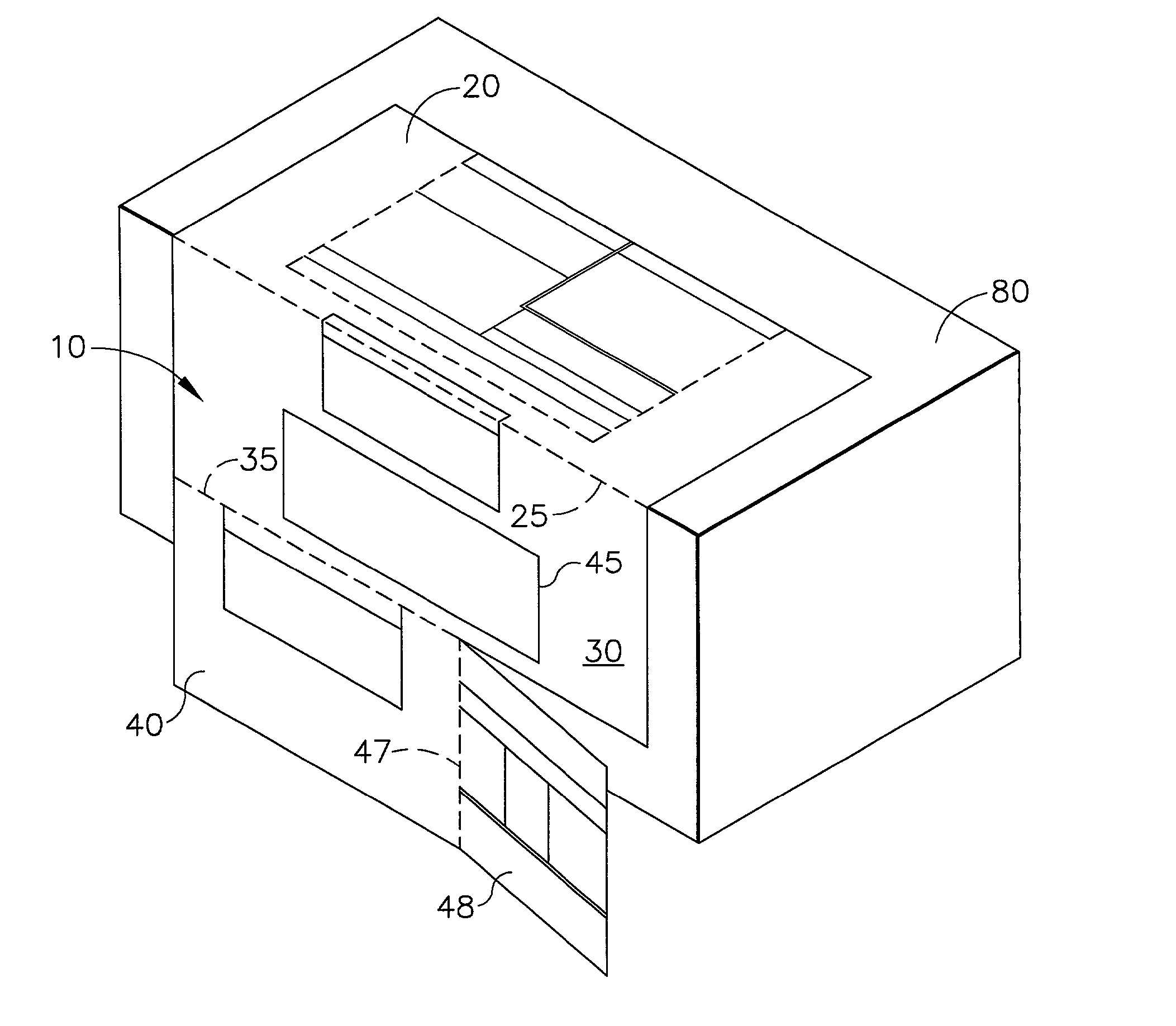

[0028] A mailer, as used in this application, shall mean a sheet configured to be capable of being affixed to an object to be mailed to a recipient, such as an envelope, magazine, package, etc.

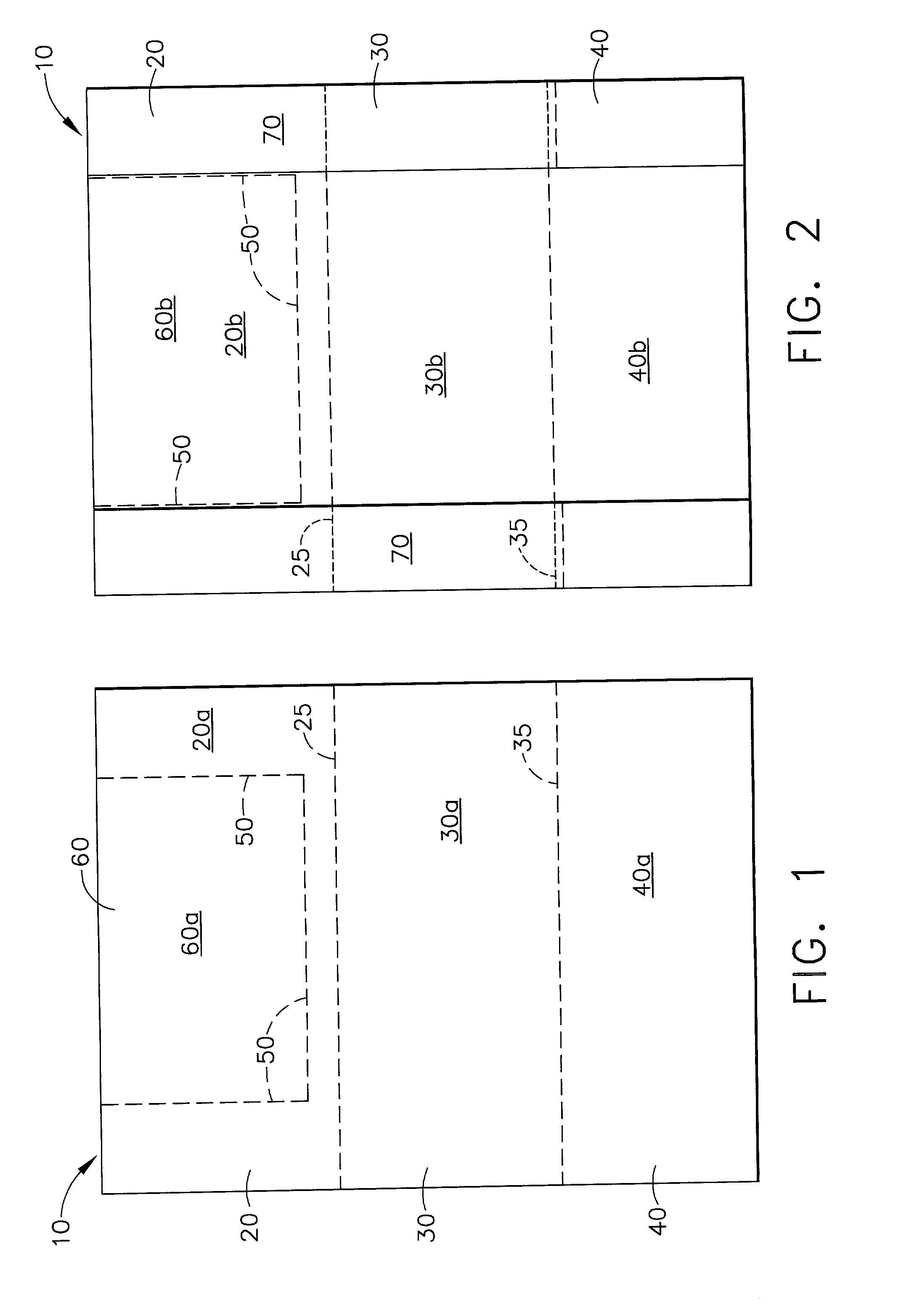

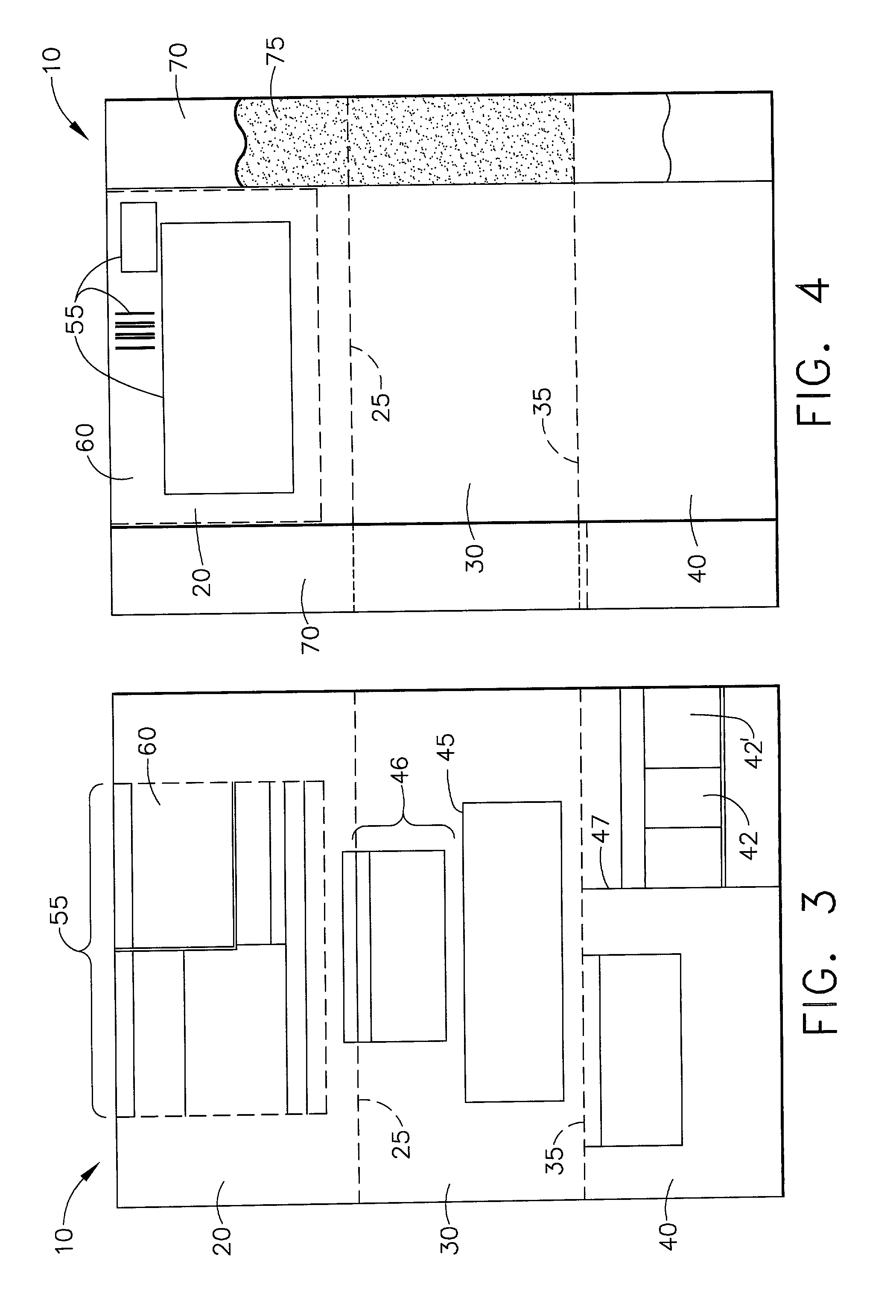

[0029] Referring to FIGS. 1 and 2, an embodiment of the mailer (10) is shown which has double sided indicia. The mailer (10) comprises a single sheet comprising a one piece integral structure. As illustrated in FIGS. 1 and 2, the mailer (10) includes integrally formed first (top) panel (20), second (middle) (30) panel, and third (bottom) panel (40). Each panel has respective outside surfaces (20a, 30a, 40a) and inside surfaces (20b, 30b, 40b) surfaces. (As used herein, the outside surface is the surface which is visible to one handling the object to be mailed after the mailer has been affixed to that object.) The panels are defined by respective, transversely extending foldlines (25, 35).

[0030] Foldlines (25, 35) may be achieved in any manner including by using tools well known in the art such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com