Device and method for patterning a surface of a polymer layer

a polymer layer and surface technology, applied in nanoinformatics, instruments, record information storage, etc., can solve the problems of limiting data rates on the order of khz rather than mhz, tip and/or media wear may be typically expected to occur, and the magnitude of an associated electrical stray field is increased by an order, so as to achieve simple and time-efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

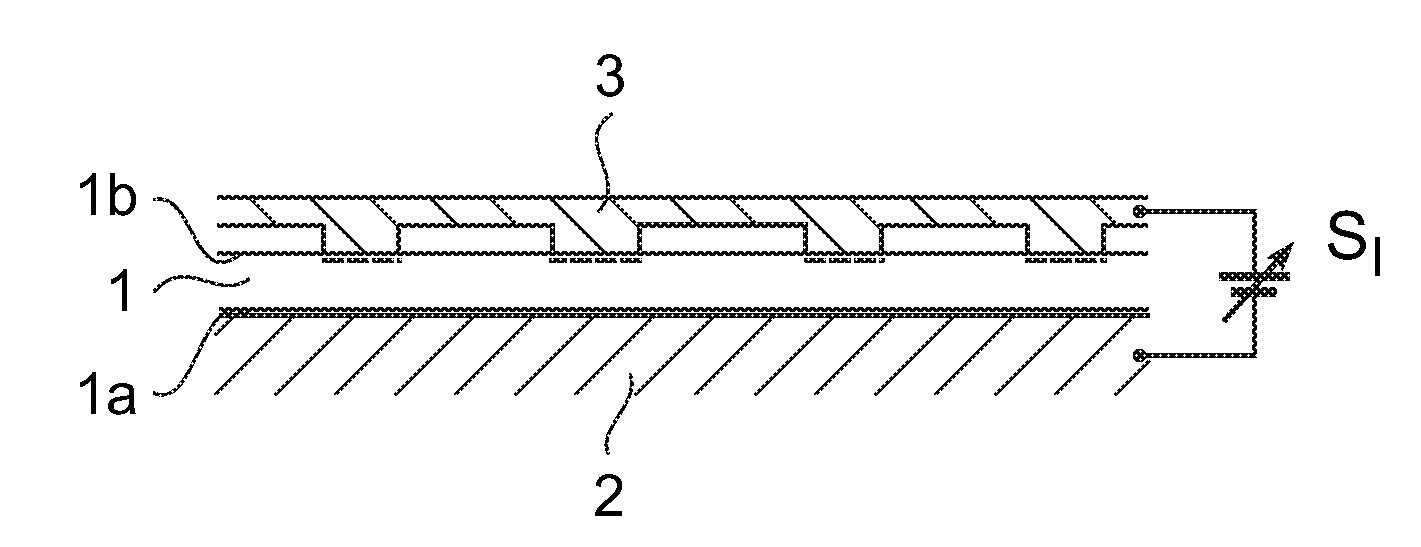

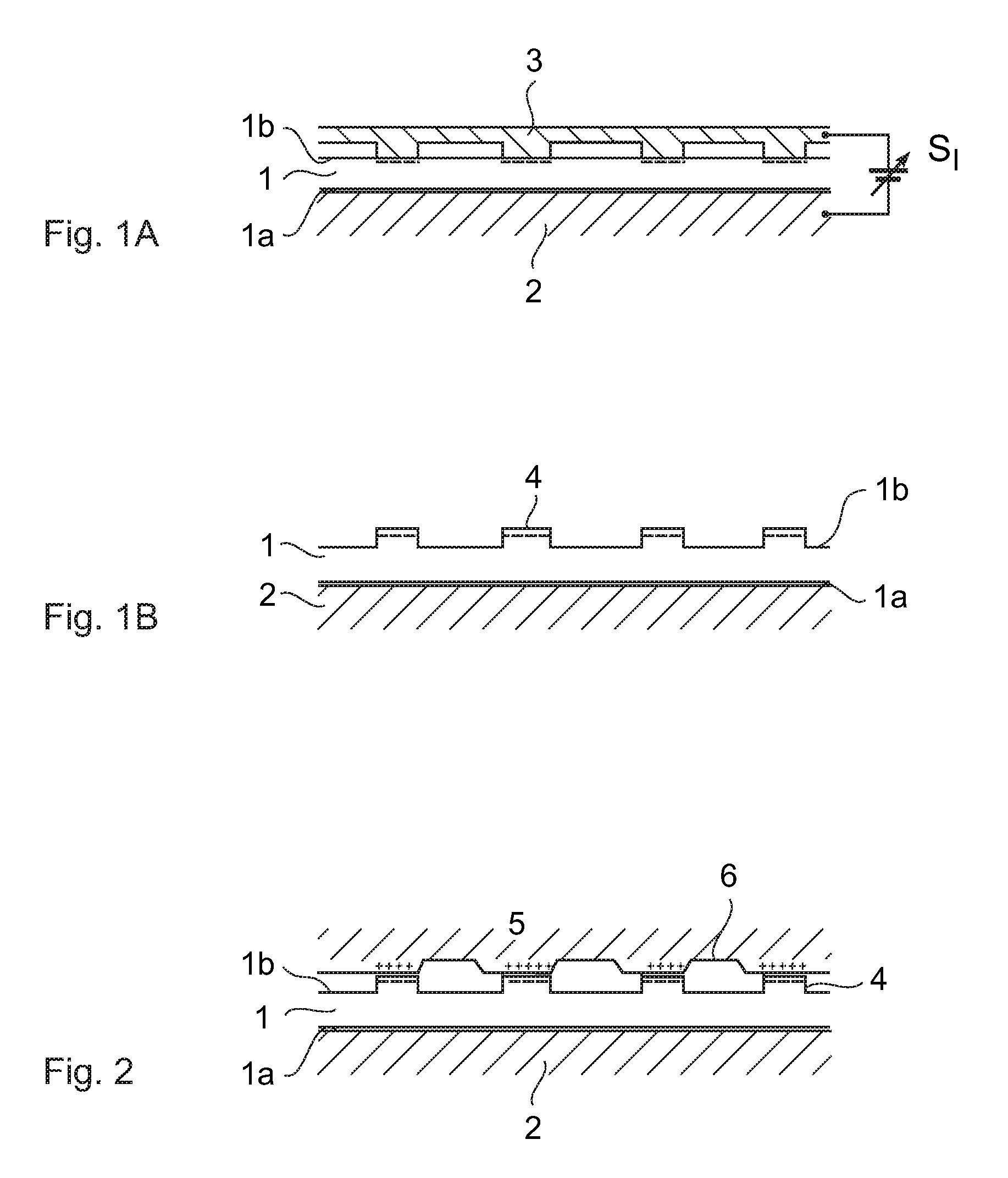

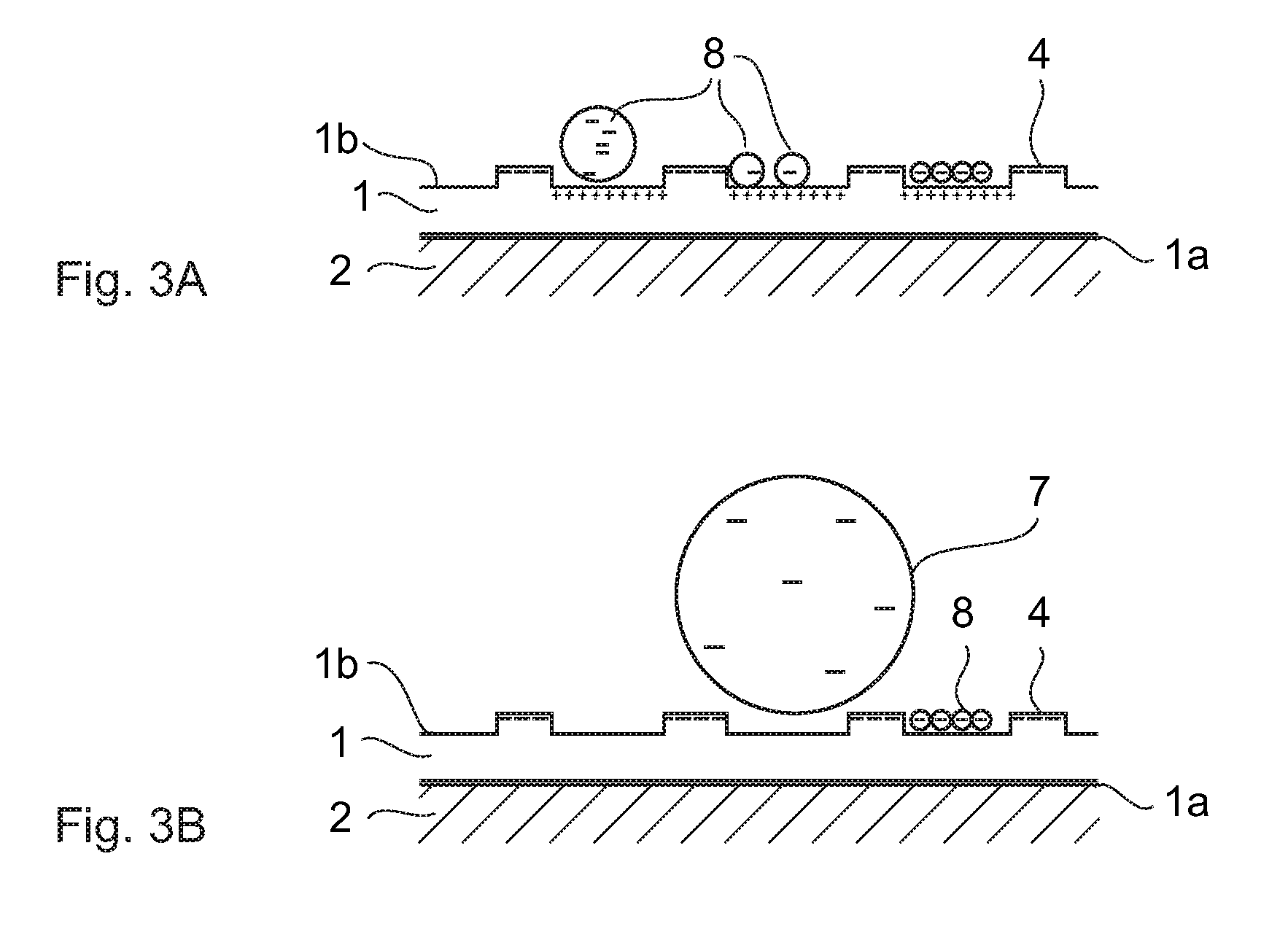

[0033]FIGS. 1a and 1b schematically illustrate the principle of an embodiment of the present invention.

[0034]A first surface 1a of a polymer layer 1 is provided on a substrate 2. It may be provided directly on the substrate 2 or on a spacer layer which may, for example, be silicon oxide. The polymer layer 1 comprises polystyrene-r-benzocyclobutene 30% random copolymer, PS-30%-BCB. The present invention is, however, not limited to PS-30%-BCB and any other polymer that is non-conducting and, optionally, cross-linkable may be used. The substrate 2 comprises silicon with an n-type doping concentration of, for example, 1016 cm−3. The substrate 2 is, of course, not limited to the use of silicon and any other material having an appropriate electrical conductance may be used.

[0035]A second surface 1b of the polymer layer 1 is provided so as to interact with at least one electrode 3 either by being in contact with or in close proximity thereto, i.e. with there being a separation between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com