Curved structural member

a structural member and curved technology, applied in the direction of girders, joists, portal frames, etc., can solve the problems of limited utilization in a number of different environments, limited use of such metal studs, and insufficient use of prior art metal studs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This disclosure of the invention is submitted in furtherance of the constitutional purposes of the U.S. Patent Laws “to promote the progress of science and useful arts” (Article 1, Section 8).

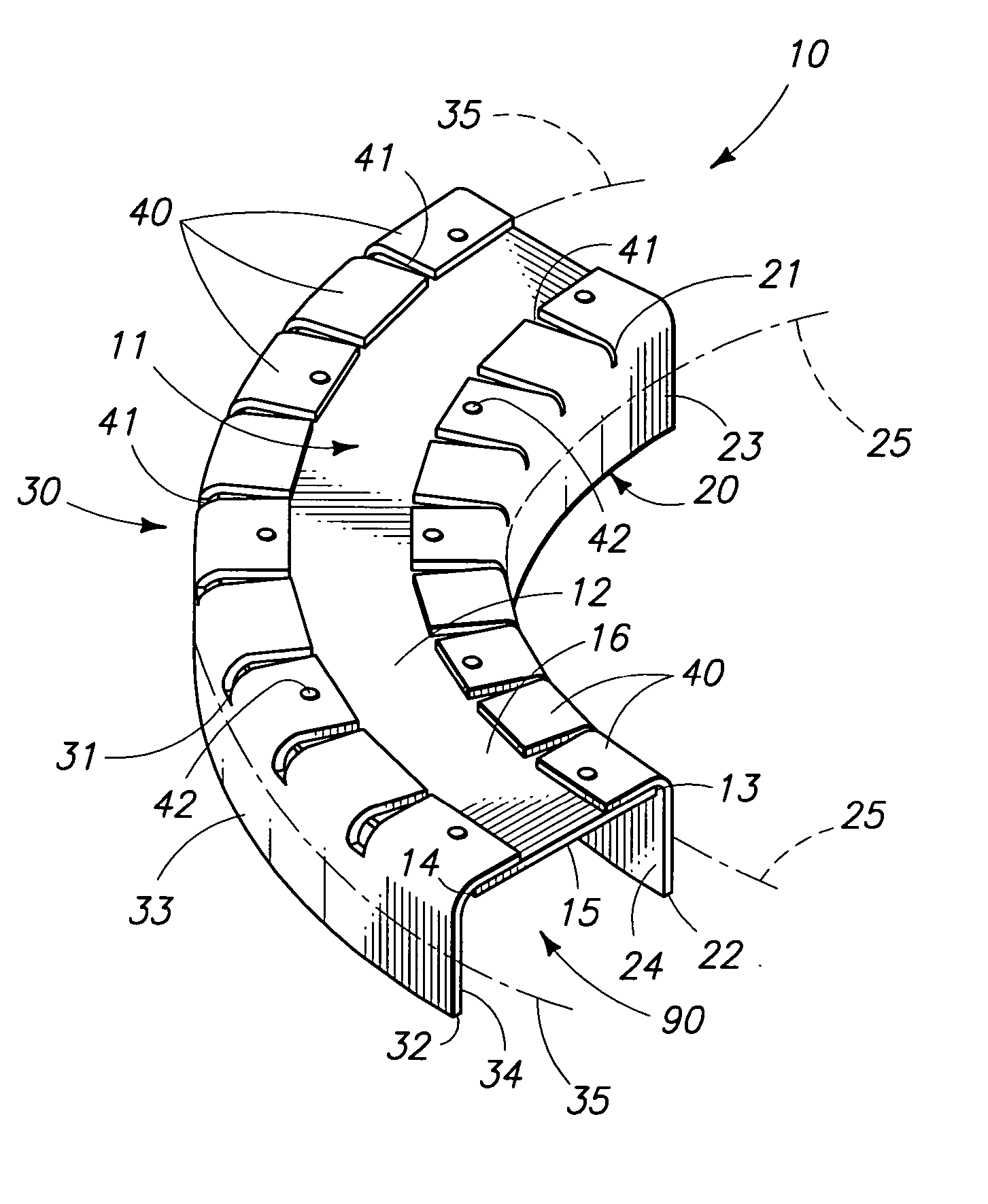

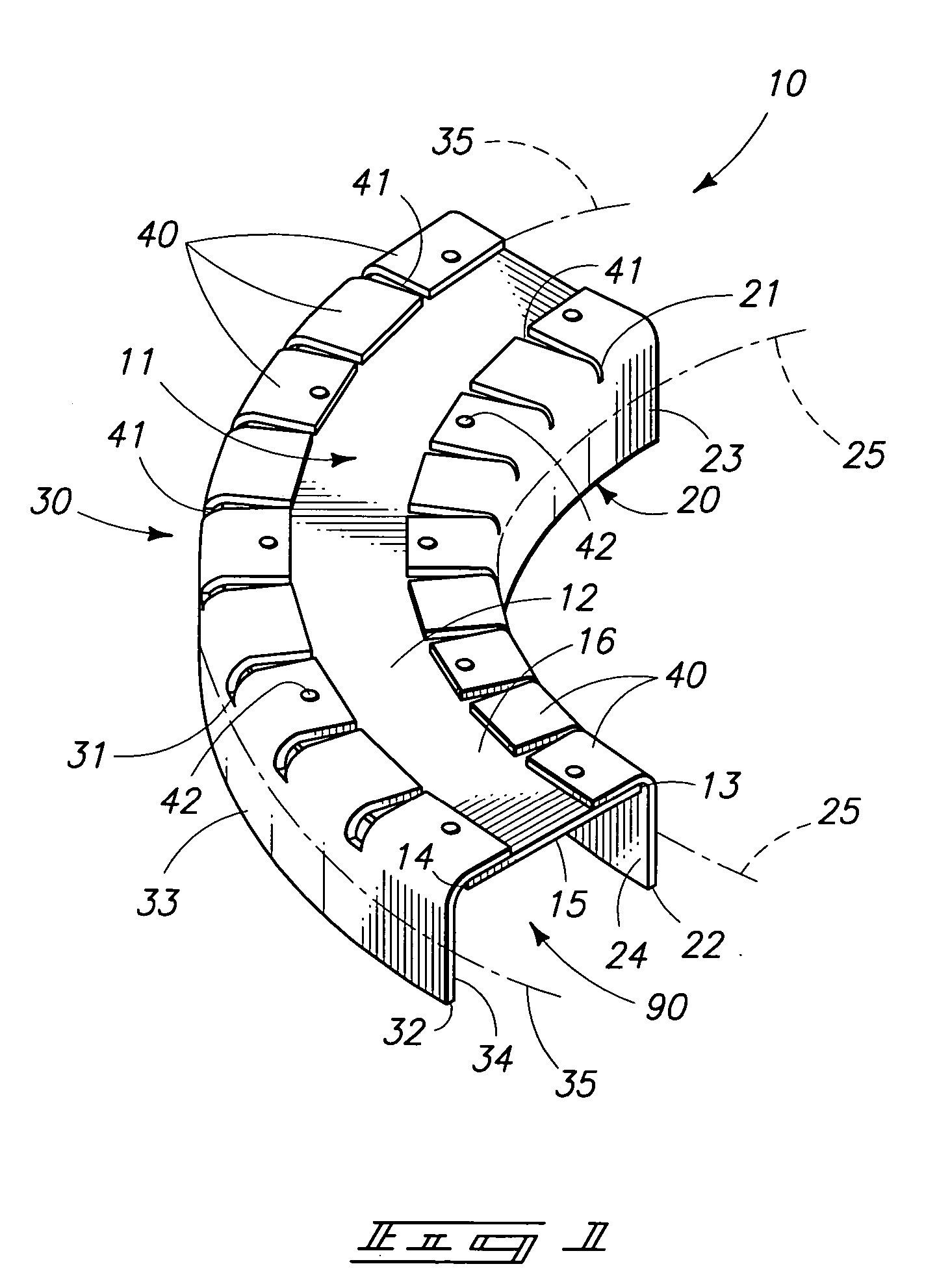

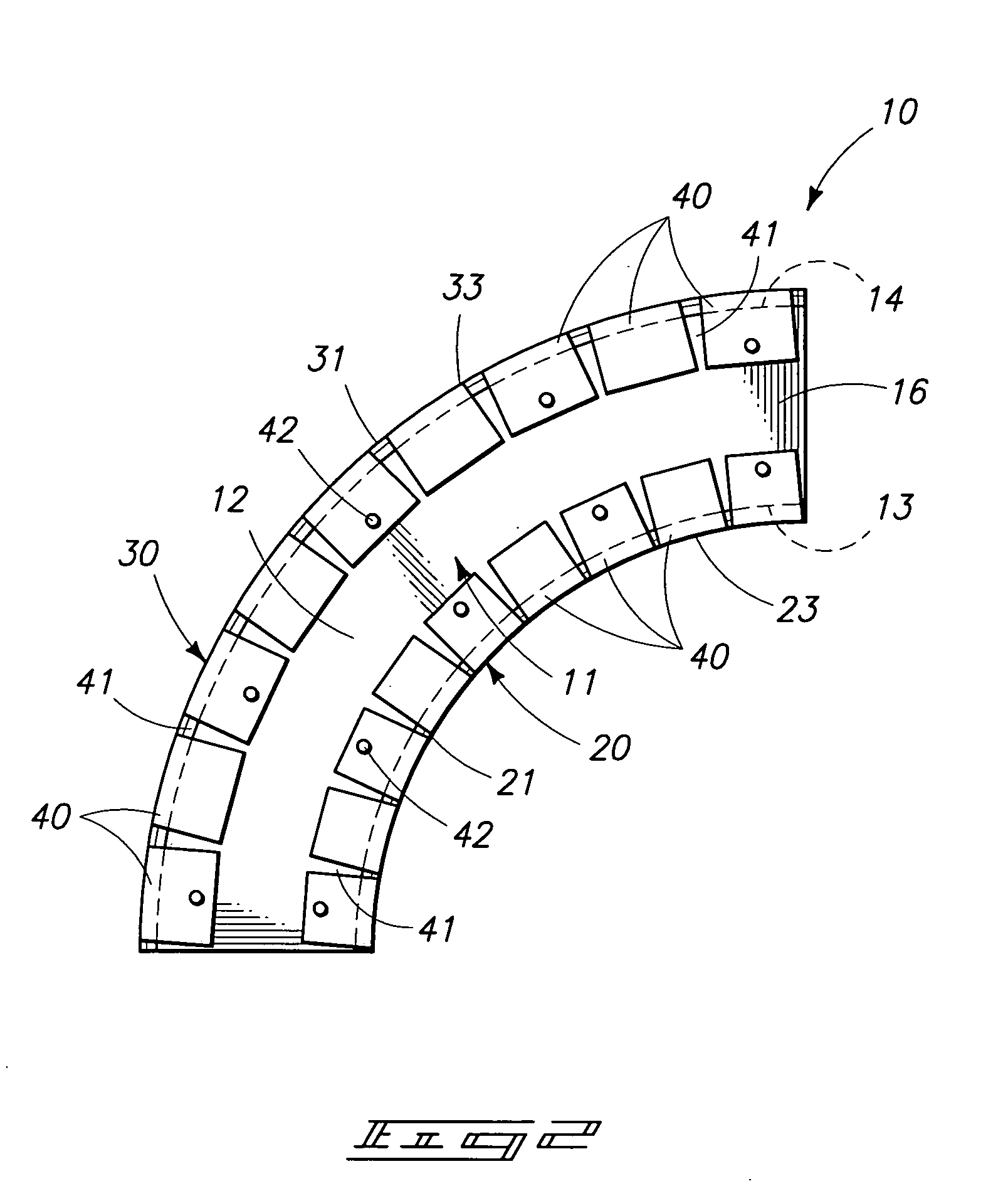

[0021] A first form of a structural member 10 of the present invention is shown in FIGS. 1-7. The first form of the structural member 10 includes a first centrally disposed web portion 11, having a main body 12, and which has opposite first and second peripheral edges 13 and 14, respectively. Still further, the main body 12 has an inside facing surface 15, and an outside facing surface 16. The inside and outside facing surfaces are substantially planar and the main body 12 is formed into a curved shape having a predetermined curvature.

[0022] The first form of the present invention 10 further includes a second portion which is generally indicated by the numeral 20, and which includes opposite first and second peripheral edges 21 and 22, respectively. The second portion further has an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com