Support for a tube bundle

a support and bundle technology, applied in the direction of stationary tubular conduit assemblies, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of vibration problems, significant cost element of the entire tube support, and relative large part of the tubes that run through the window remain unsupported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

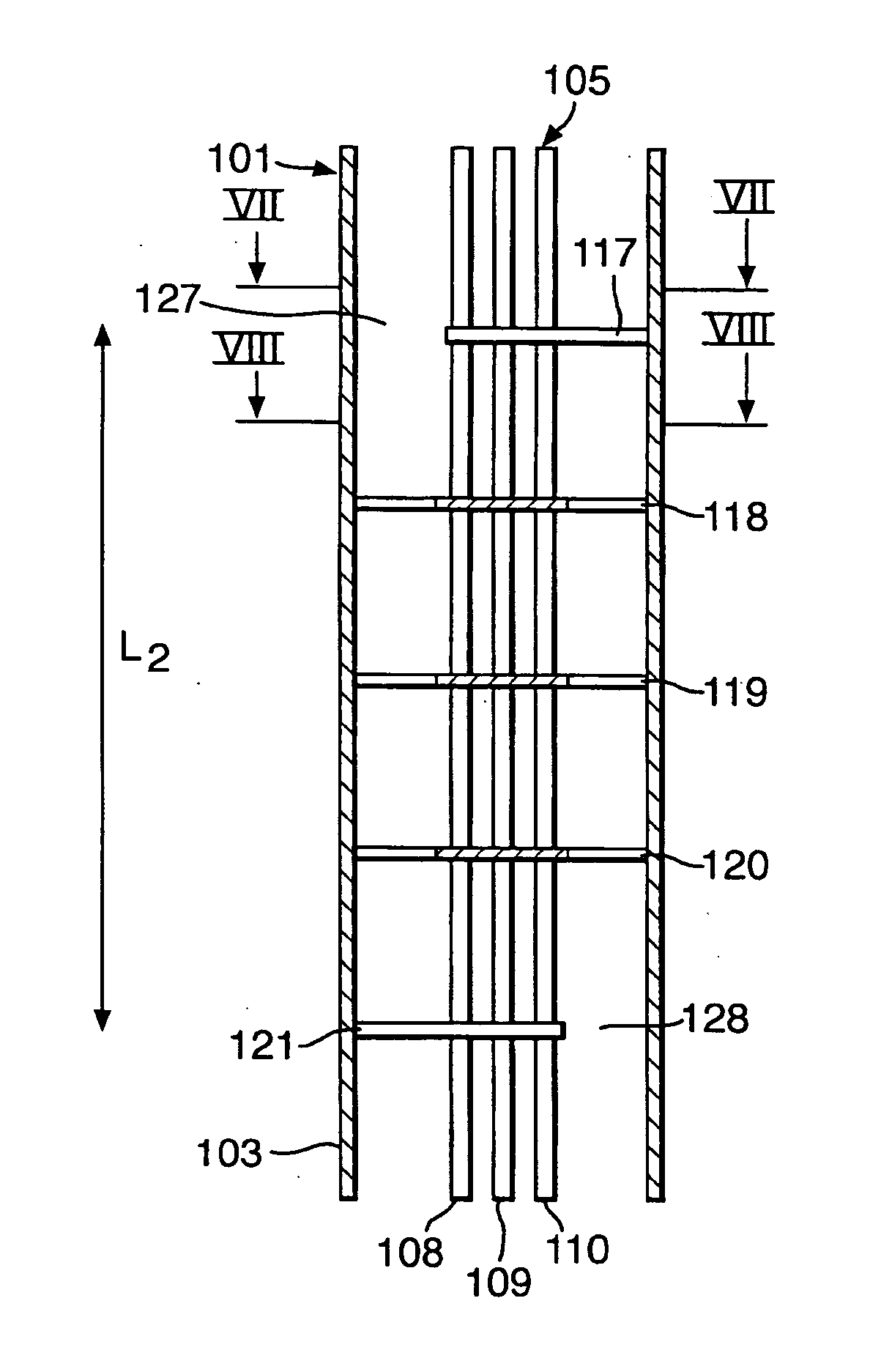

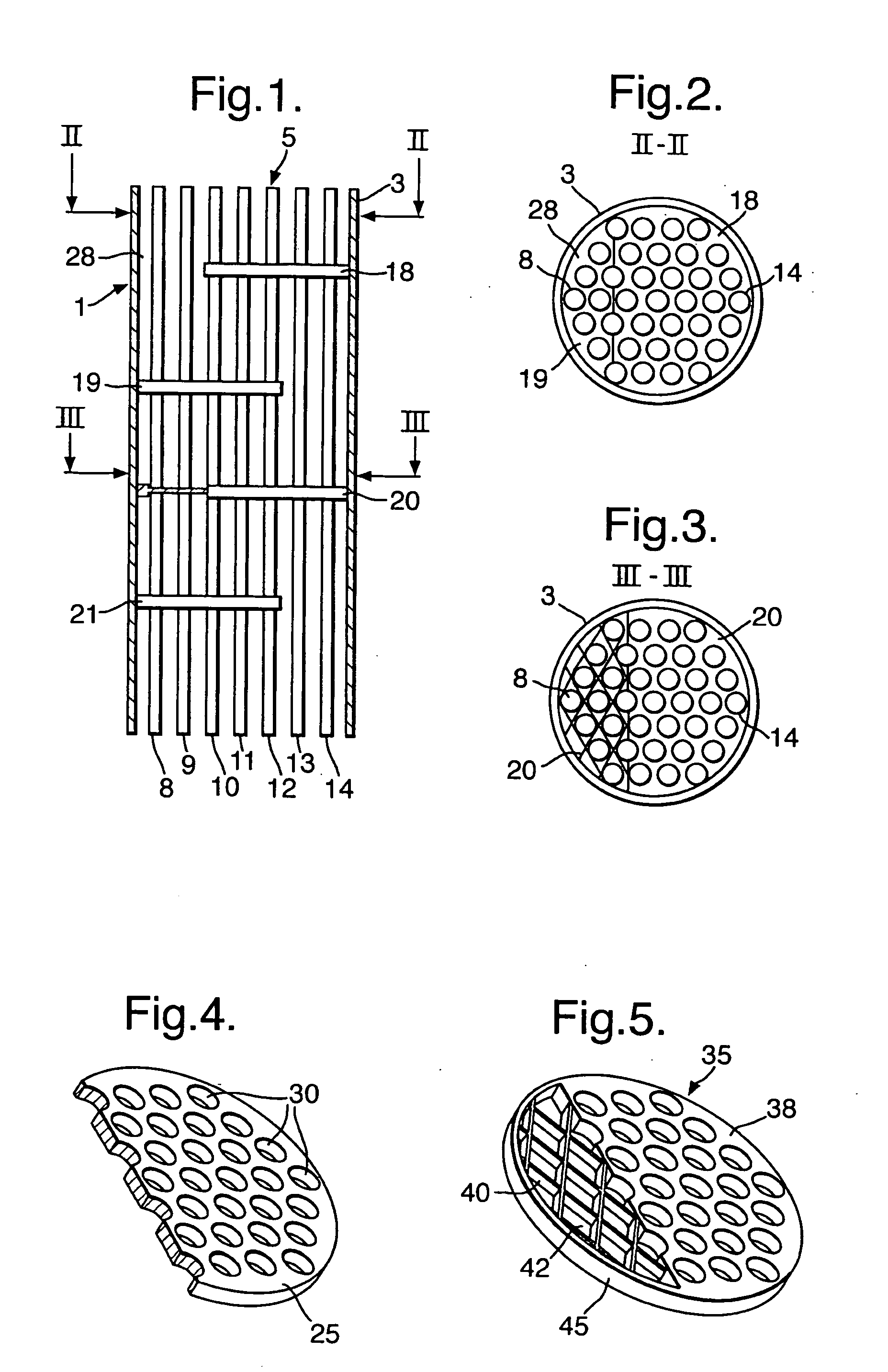

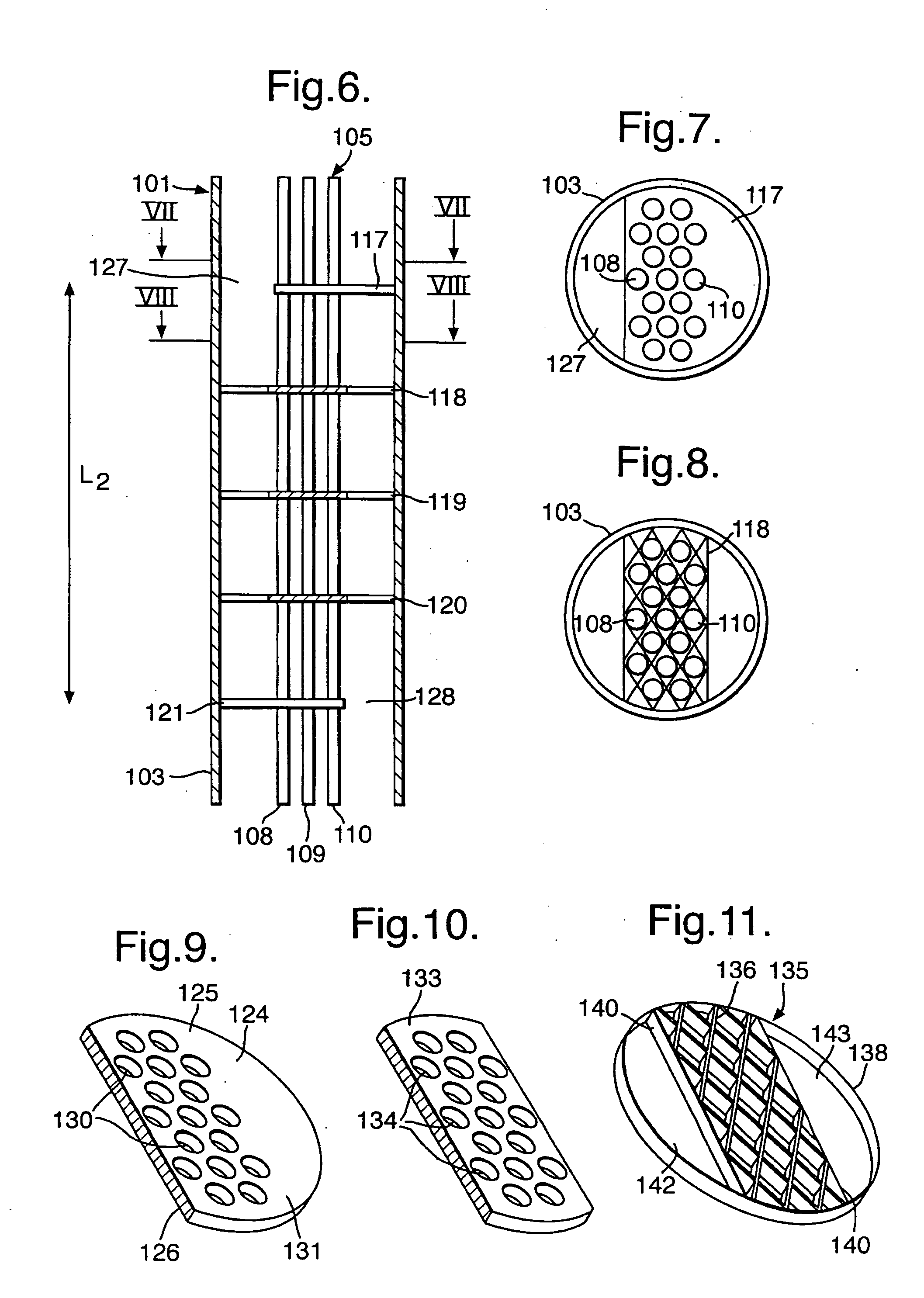

[0040] Reference is now made to FIGS. 6-11, and the present invention will now be discussed.

[0041]FIG. 6 shows part of a Texas tower heat exchanger 101 in longitudinal cross-section, and FIGS. 7 and 8 show two cross-sections along lines VII-VII and VIII-VIII, respectively. The heat exchanger 101 has a vertical cylindrical shell 103 and a bundle of tubes 105 running through the central part of the shell 103. The tubes 108,109 and 110 are visible in FIG. 6. The Texas tower may for example have a height of 24 m and a diameter of 2.5 m.

[0042] The support for the tube bundle 105 comprises the five support plates 117,118,119,120,121 shown in FIG. 6 as support elements. The plates are spaced from each other along the length direction of the tubes 108-110.

[0043] Support plates 117 and 121 are conventional segmental baffles 124 as shown enlarged in FIG. 9. These segmental baffles are manufactured from a circular plate 125 from which a segment has been cut off along line 126 so that windows...

third embodiment

[0047] Reference is now made to FIGS. 12-13, and with reference to these FIGS. the invention will be discussed.

[0048] The horizontal heat exchanger 201 with shell 203 through which the tube bundle 205 runs is an example of such a design. FIG. 12 shows part of a longitudinal cross-section, and it will be understood that the heat exchanger may be much longer, and that more support plates than shown may be arranged. The tube bundle 205 includes tubes 208, 209, 210, 211, 212, 213, and 214. The Figure does not show the end parts of the tubes with the tube sheet.

[0049] The tubes are supported by segmental baffles 218, 219, 220. As further support against tube vibrations expanded metal support plates 221,222 are arranged. The segmental baffle support elements and the expanded metal support elements are alternatingly arranged at a fixed spacing along the length direction of the tubes 205. The spacing between adjacent segmental baffles, e.g. 218 and 219, is L3.

[0050] The segmental baffle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com