Method and device for controlling an agricultural working machine

a technology for working machines and agricultural machinery, applied in the direction of guiding agricultural machines, agricultural tools and machines, mowers, etc., can solve the problems of increasing costs, damage to plants, and inability to use systems of this type to advance the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

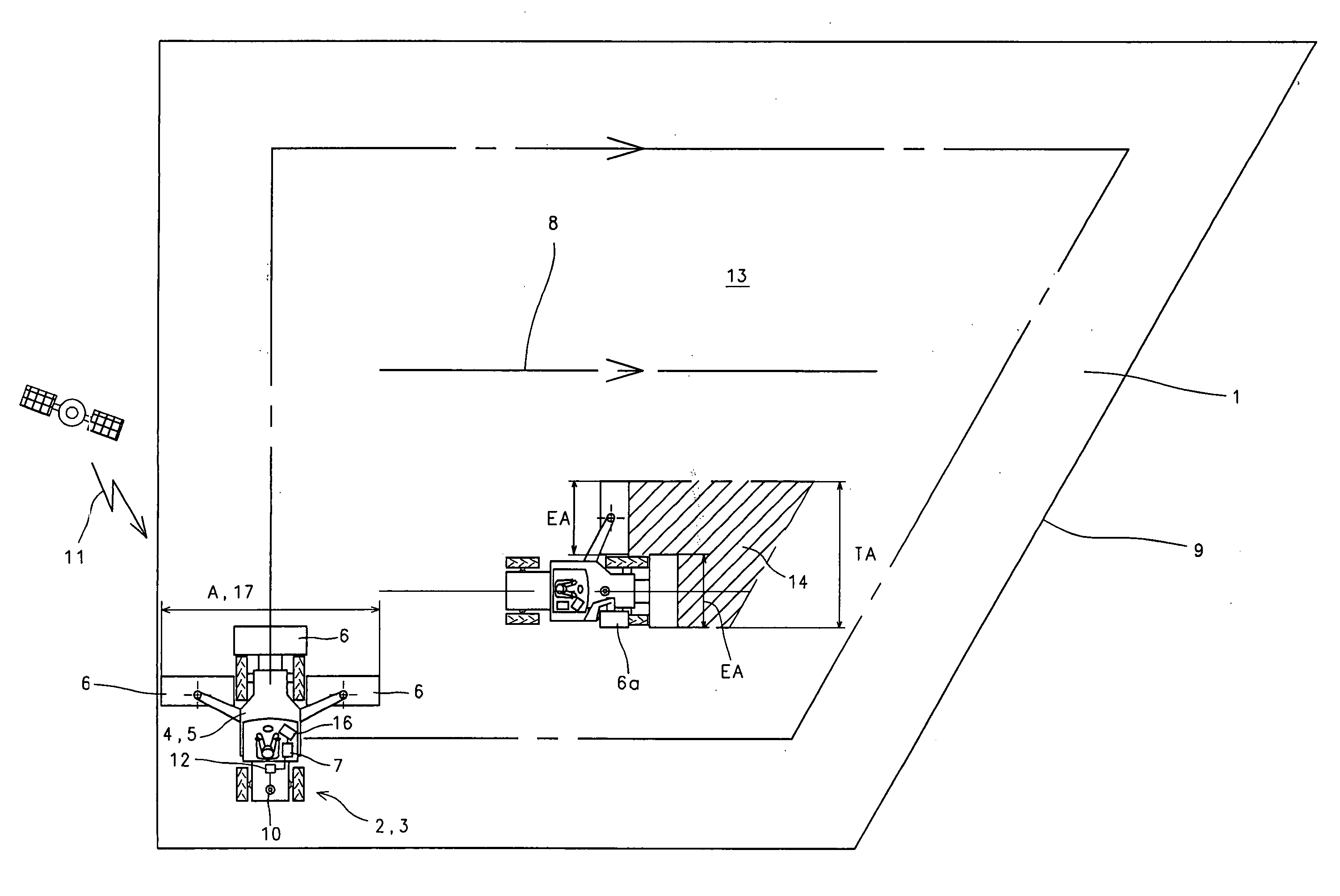

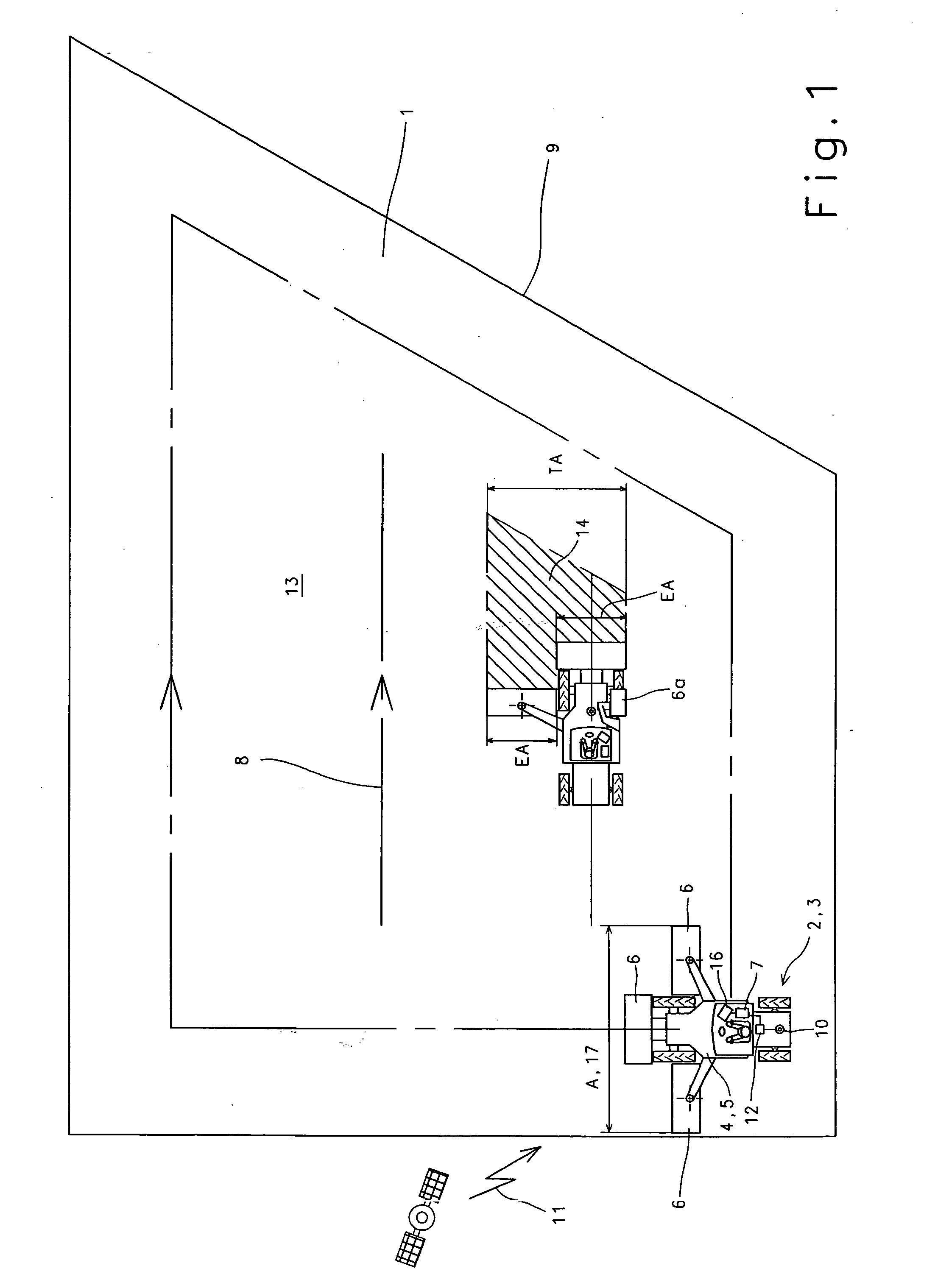

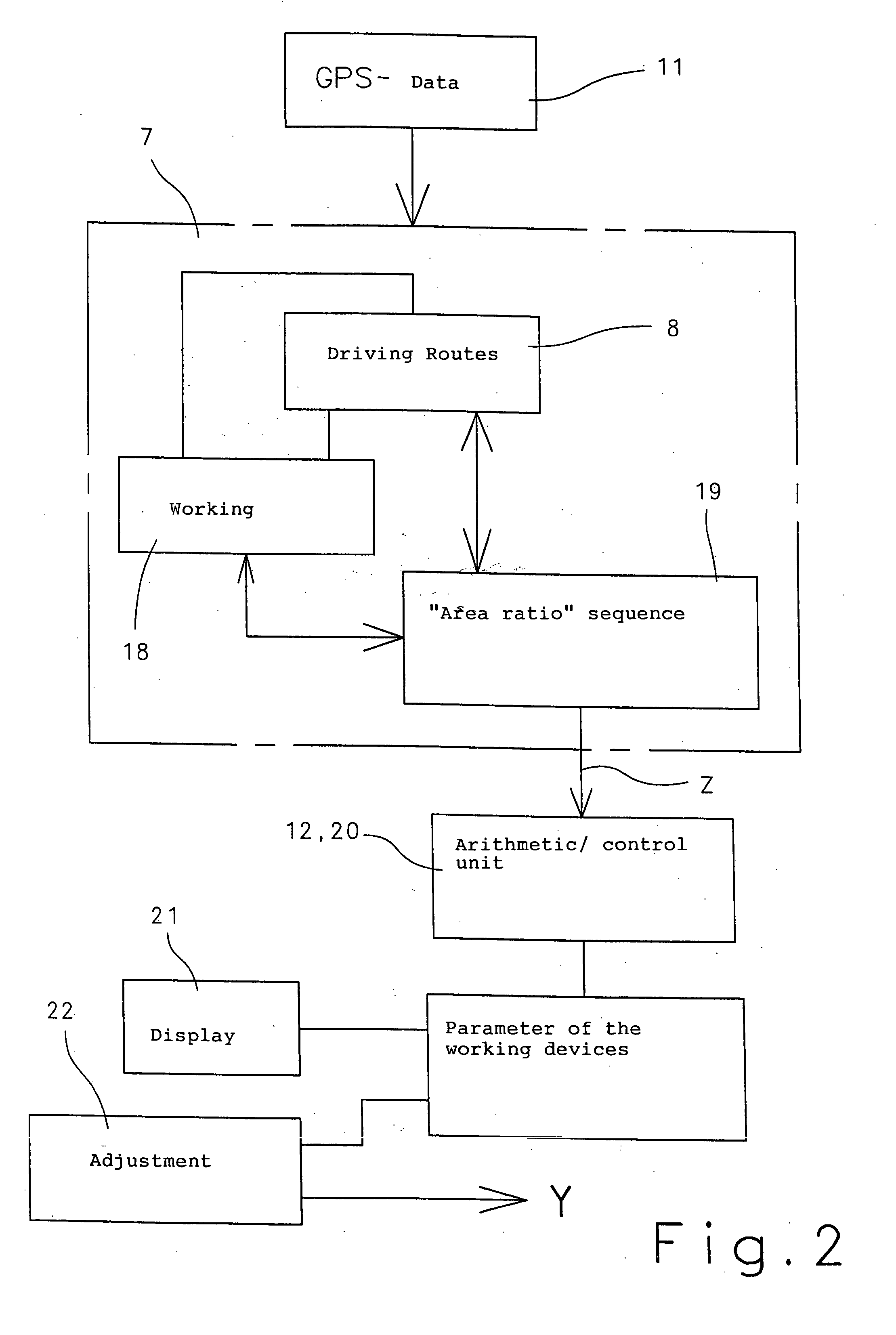

[0019]FIG. 1 shows a schematic illustration of a territory 1 to be worked, said territory being driven over and worked by an agricultural working machine 2 designed as a self-propelled mower mechanism 3. The self-propelled mower mechanism 3 is a carrier vehicle 4 which, in the simplest case, can be designed as a tractor 5, to the front and sides of which working attachments 6 designed as mowing units are assigned. In addition, the agricultural working machine 2 includes a route planning system 7 known per se that is capable of subdividing territory 1 to be worked into “driving routes”8 to be worked by the agricultural working machine 2. These driving routes 8 are usually generated in a first working step by the agricultural working machine 2 first driving around the territory 1 to be worked, following outer contours 9, so that the route planning system 7 can then determine further driving routes 8 as a function of working width A, thereby ultimately ensuring that the territory 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com