Potted plant cultivate assembly

a technology for cultivating plants and plants, applied in the field of cultivating assembly, can solve the problems of waste of water and insufficient space in the garden shop, and achieve the effect of reducing waste of water and increasing the area of the garden shop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

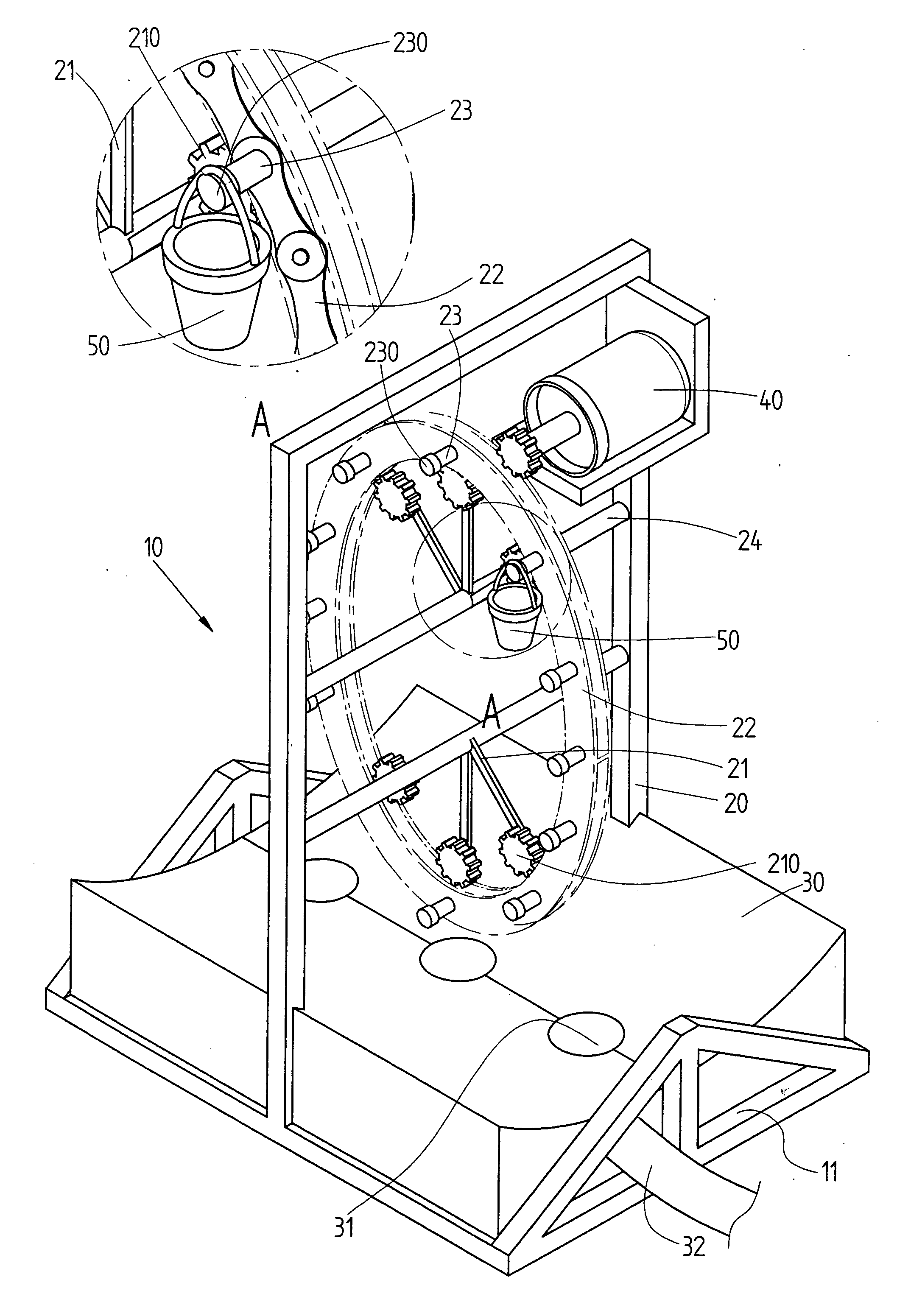

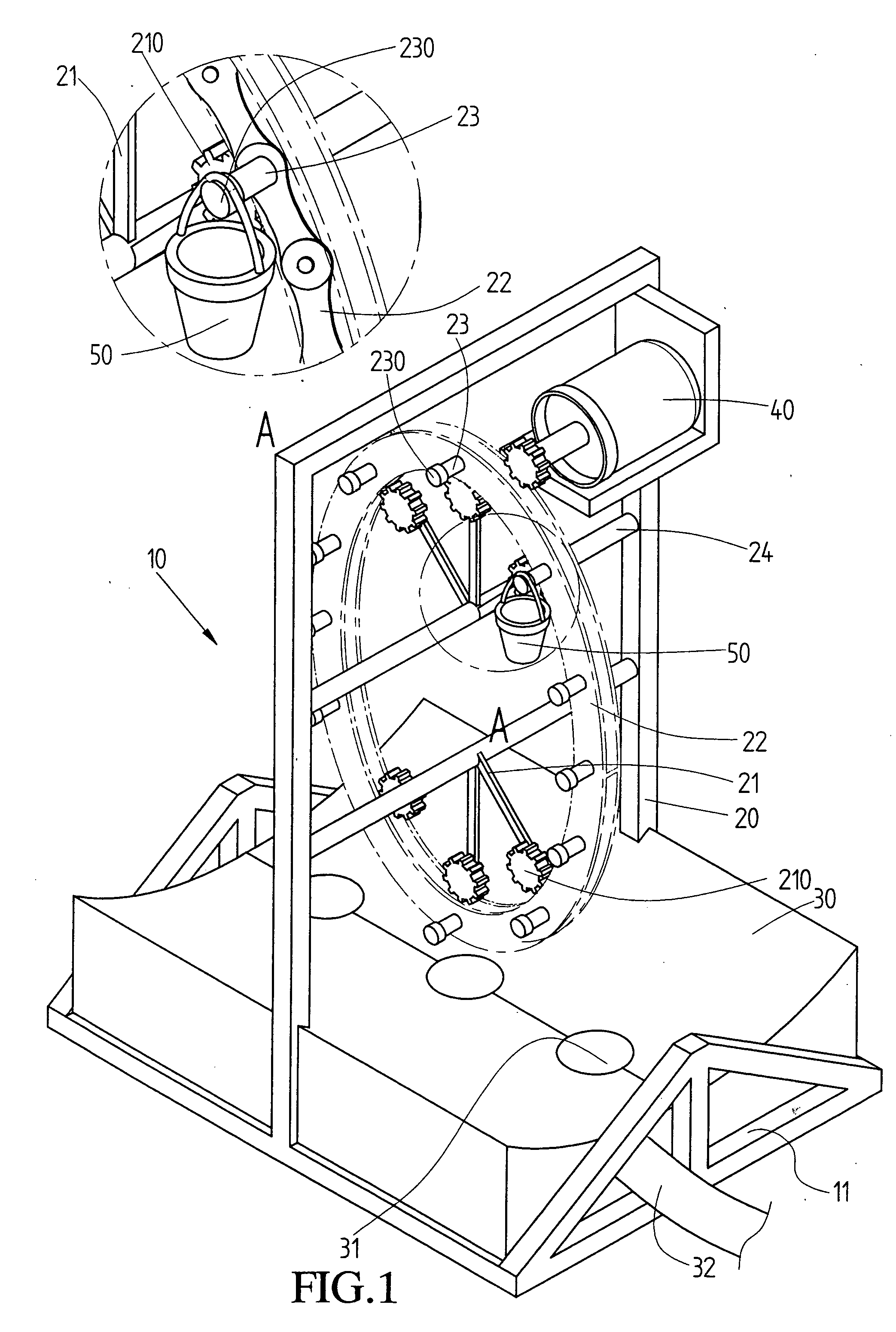

[0012] Referring to the drawings and initially to FIGS. 1-2, a potted plant cultivate assembly in accordance with the present invention comprises a frame (10) and a cycle device (not numbered) mounted on the frame (10).

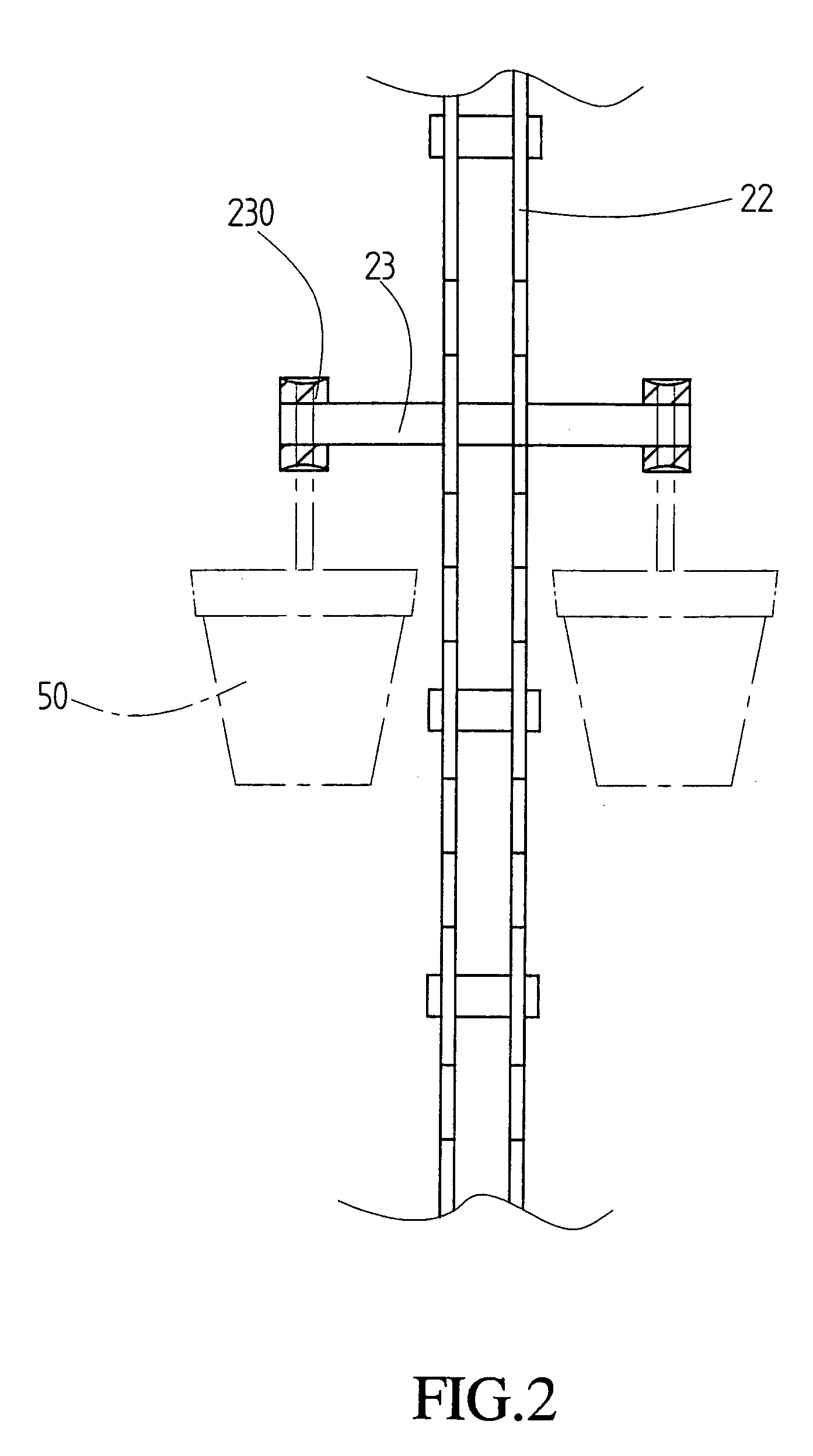

[0013] The frame (10) includes a base member (11) and a doorframe (20) is vertically mounted on the base member (11). Two lateral rods (24) horizontally mounted to two opposite sides of the doorframe (20). Three rods (21) radially extends from each of the two lateral rods (24). A chain wheel (210) is pivotally mounted to a free end of each of the six rods (24). An endless chain (22) is mounted around the six chain wheels (210) and supported by the six chain wheels (210). The endless chain (22) has two opposite sides each having a series suspensions (23) laterally pivotally extending therefrom by a first bearing (not numbered). Each suspension (23) is parallel to the base member (11). A second bearing (230) is laterally mounted to a free end of each of the suspensions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com