Wipe dispensing system

a wipe and dispensing system technology, applied in the field of thin profile wipe dispensing containers, can solve the problems of easy drying of wipes, difficult transportation and storage, and dry out of wipes in softpacks, and achieve the effect of improving the dispensing of one wip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

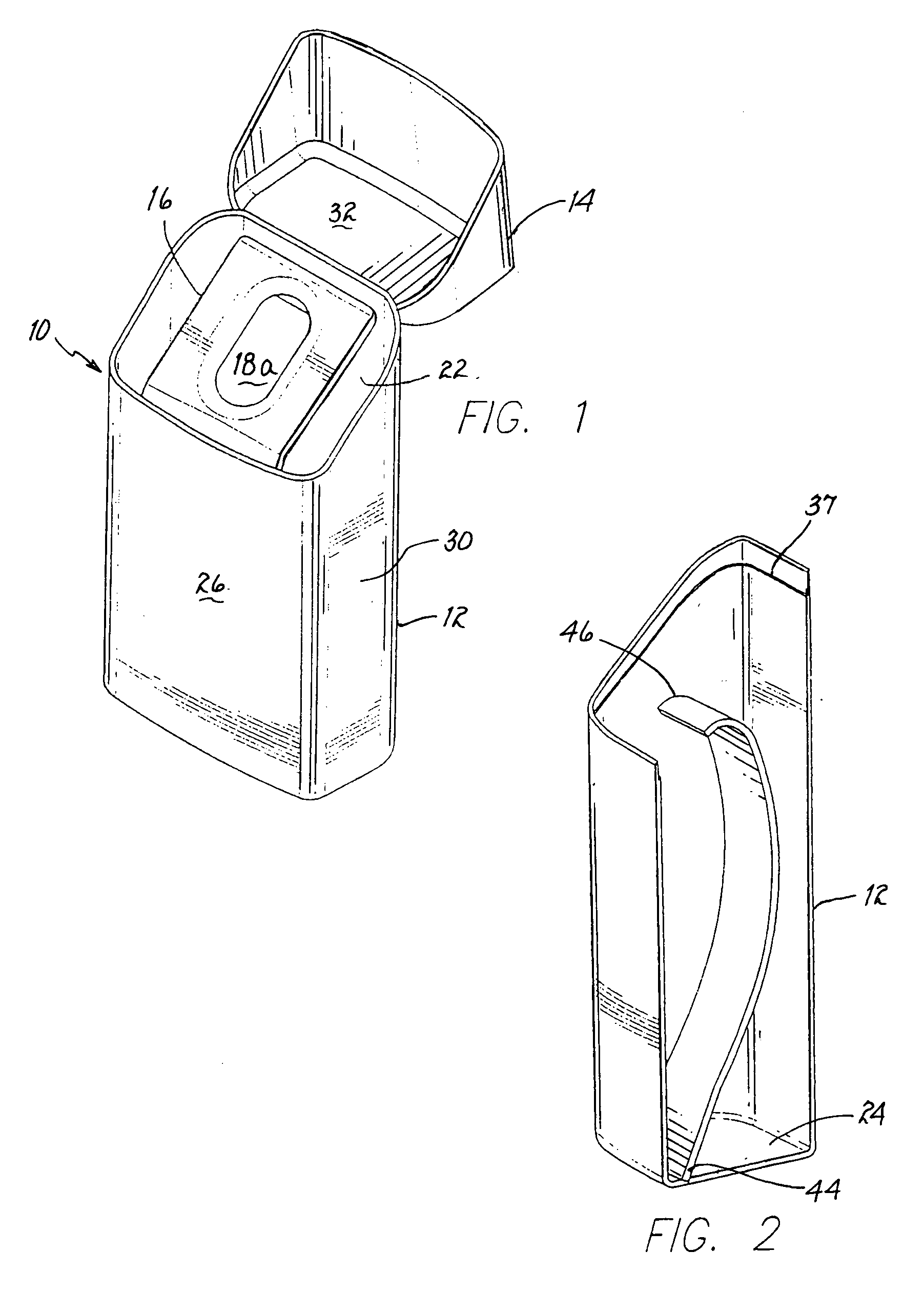

[0029] As shown in the drawings for purposes of illustration, the present invention relates to an improved dispensing container, generally designated in the accompany drawings by the reference number 10. The method for dispensing is also provided. The improved dispensing container is specifically designed to have substantially improved storage and dispensing features over conventional wipe dispensers.

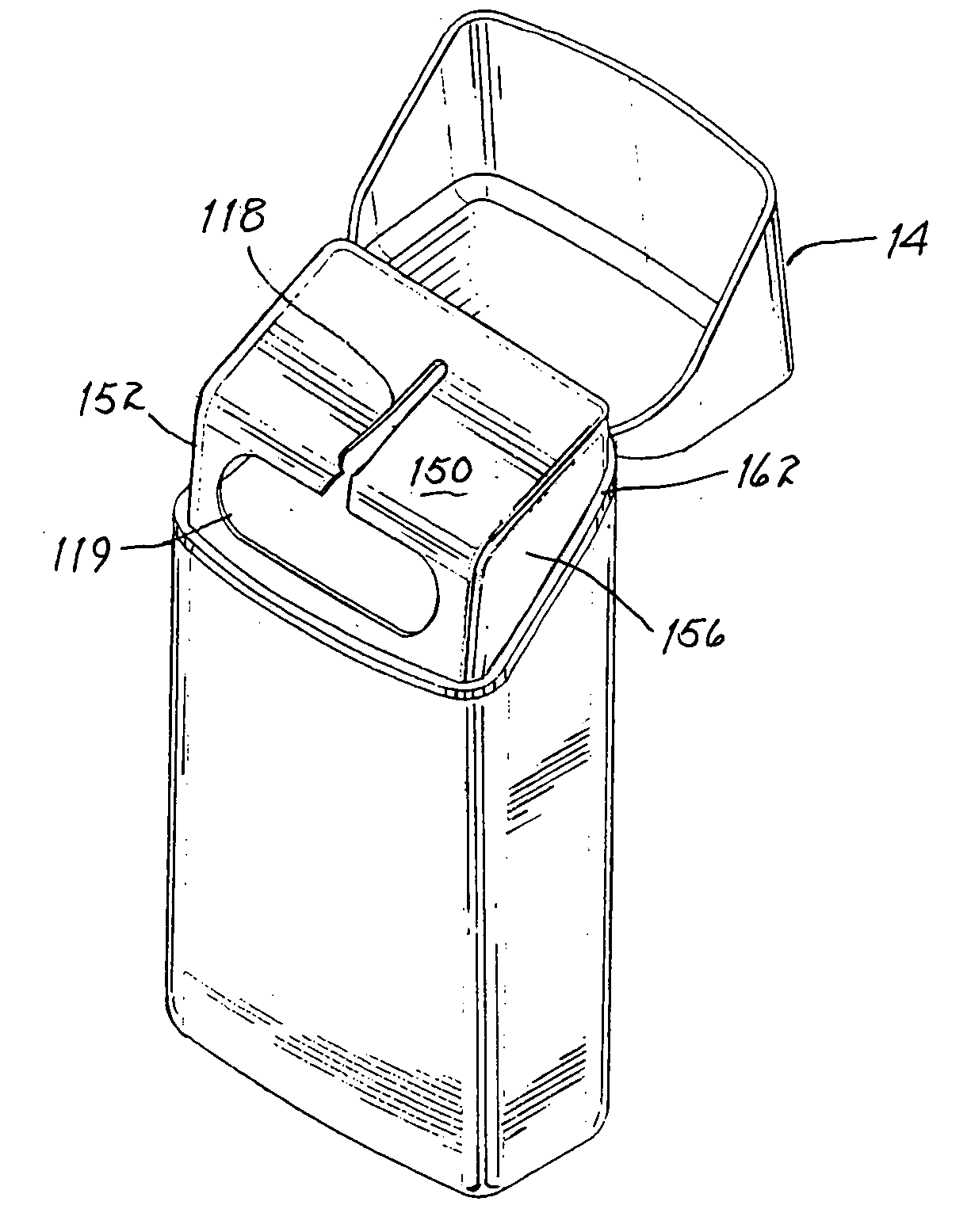

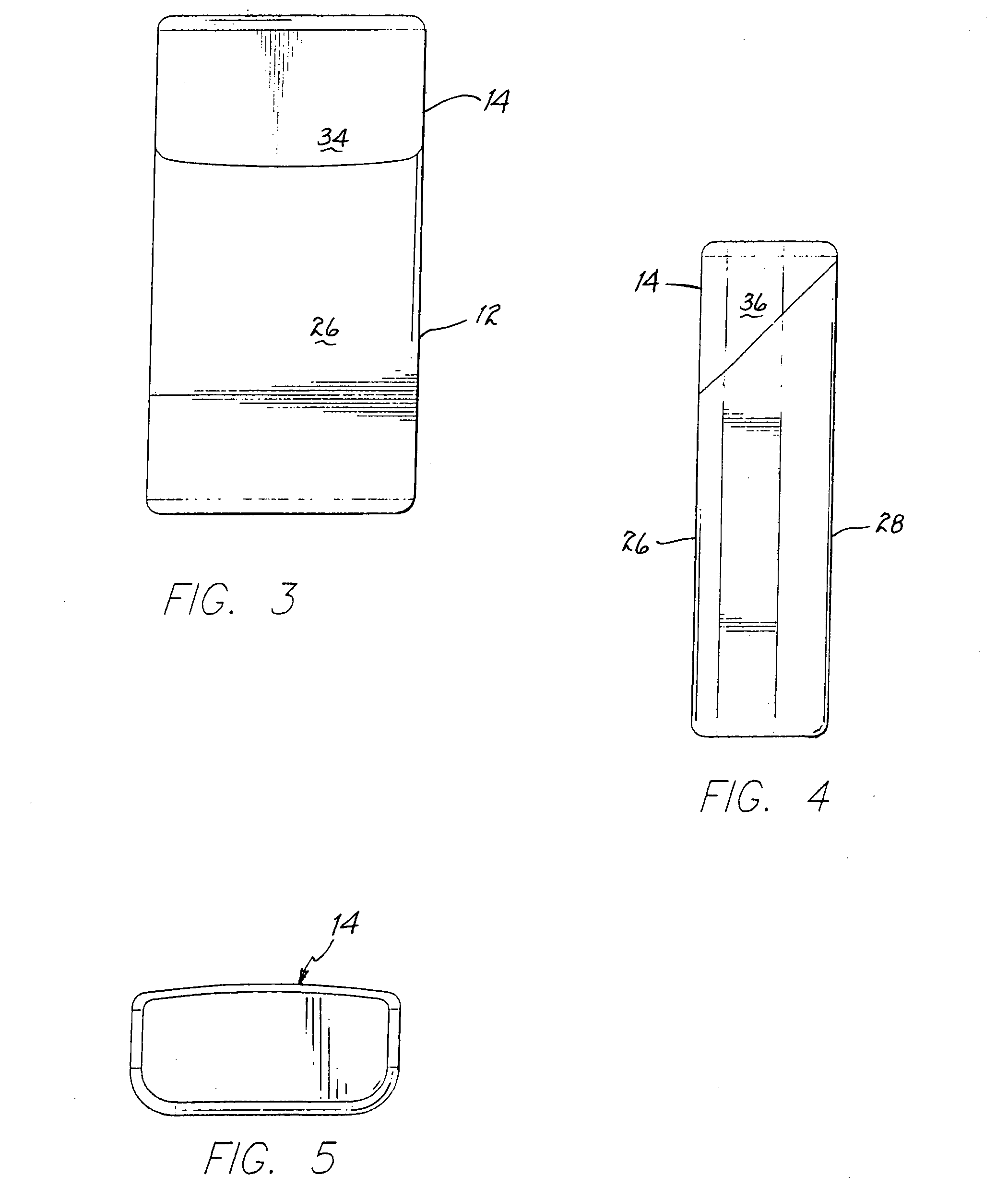

[0030] In accordance with the present invention, and as illustrated with respect to preferred embodiments in FIGS. 1-18, the dispensing container 10 comprises, generally, a substantially thin-profile container body 12 having a generally upright and open-ended shape for receiving and containing a stack of wipes (not shown), a hinged lid 14 that may be pivoted open to provide access to the wipes and pivoted closed to be substantially flush with the container body 12, and a bridge 16 or 116 defining a dispensing aperture 18a-18m or 118 in combination with a finger opening 119. The dispens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com