Packer washout assembly

a technology for washing out and packing tools, which is applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of preventing the release of packing tools, time-consuming and expensive procedures, and the need for improved tools to be cost-effective and substantially maintenance-fr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

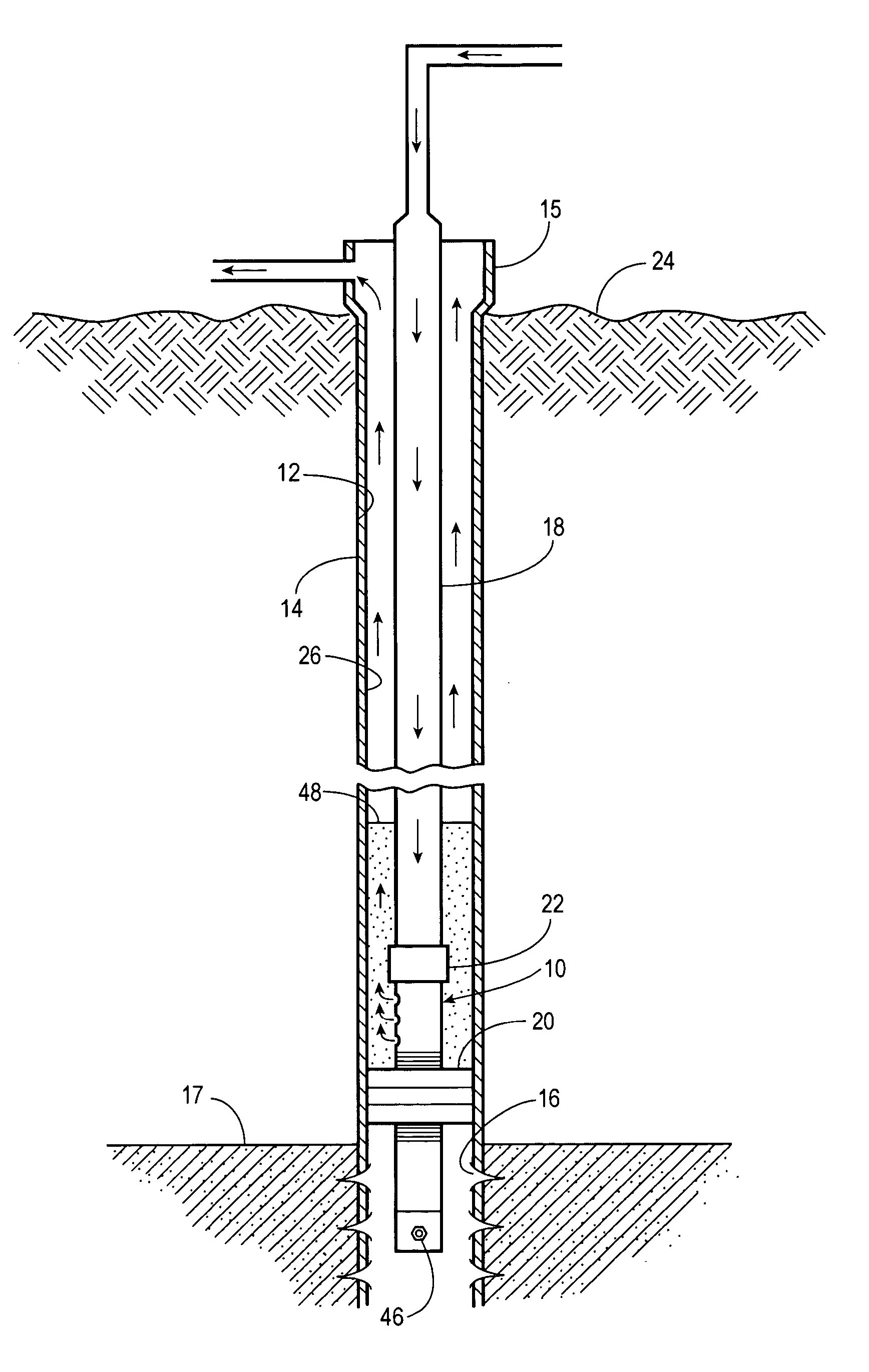

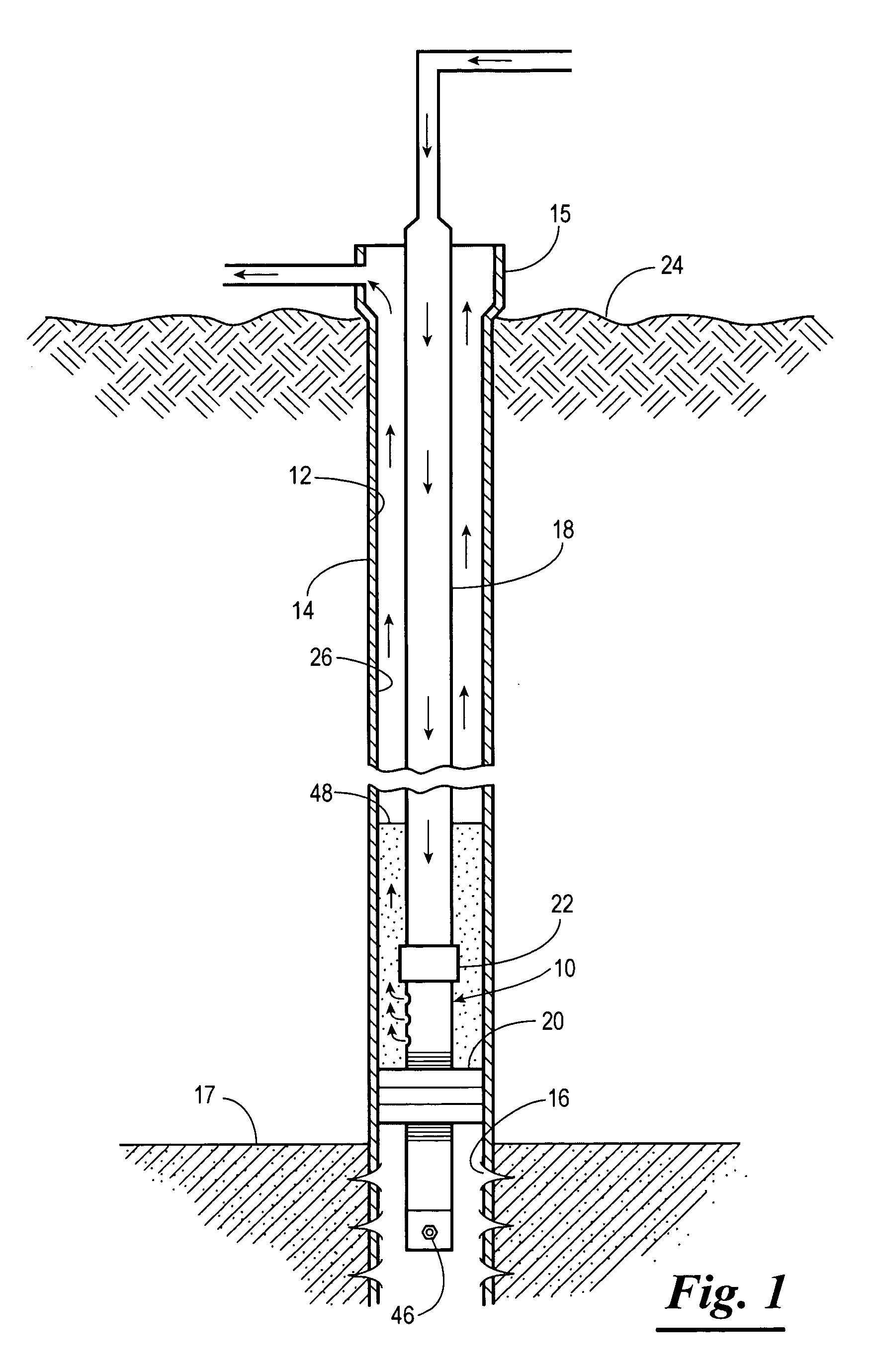

[0012] Referring now to FIG. 1, a packer washout assembly 10 constructed in accordance with the present invention for removing debris, such as sand, silt, shale, and rust, from the top of a packer 20 to permit the packer to be released is schematically illustrated. A well bore 12 is shown to be lined with a casing 14 extending down from a wellhead 15. The casing 14 provides a permanent borehole through which production operations may be conducted. The casing 14 is affixed in the well bore 12 in a conventional manner, such as by cement (not shown), and is provided with perforations 16 open to a producing subterranean formation 17.

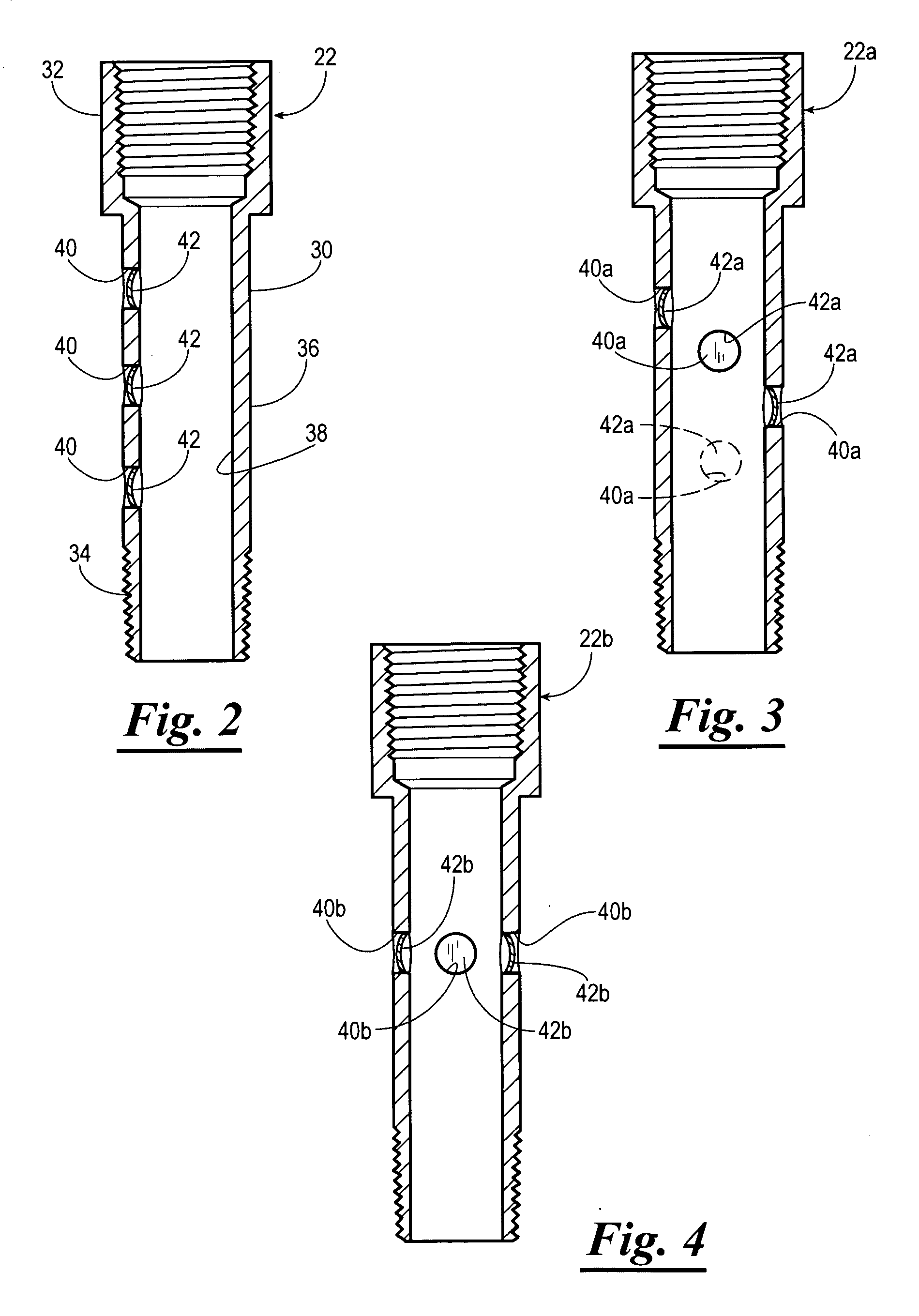

[0013] The packer washout assembly 10 includes a tubing string 18, a packer 20, and a packerwashout sub 22. The tubing string 18 provides fluid communication between the producing subterranean formation 17 and a surface 24 such that a reservoir fluid (not shown), for example oil and / or natural gas, is produced through the tubing string 18. The casing 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com