Joining member having pivotal components for net support structure

a technology of pivotal components and net support structures, which is applied in the direction of ski bindings, water skis, skiing, etc., can solve the problems of sleeve type connecting devices that are not reliable, patents suffer from couple, and net support structures tend to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

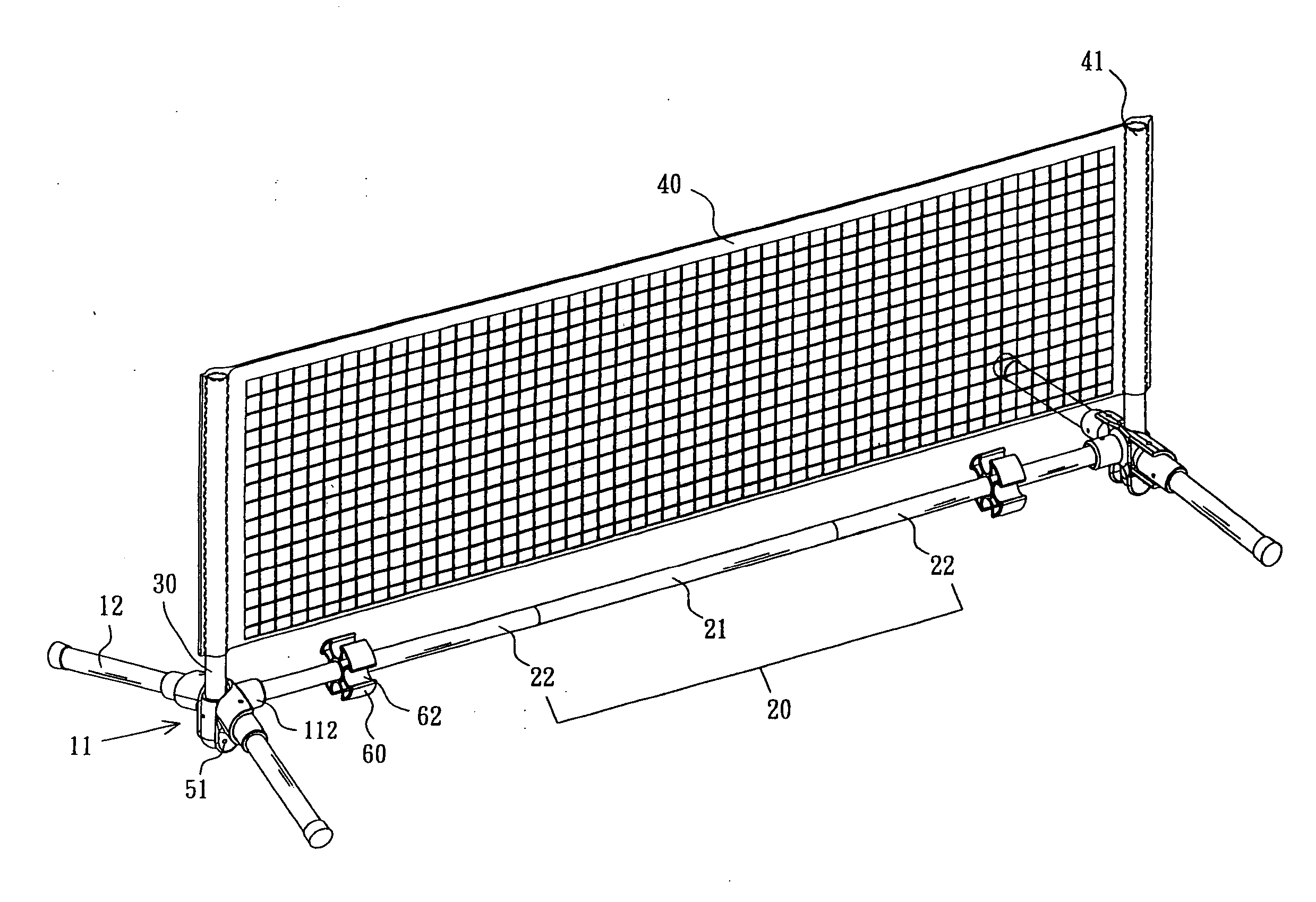

[0019] Referring to FIGS. 3 to 7, a net support structure in accordance with a first preferred embodiment of the invention comprises two leg devices 10, a cross member 20, two uprights 30, and a net 40. Each component is discussed in detailed below.

[0020] The leg device 10 comprises a substantially T-shaped joining member 11 including two opposite grooves 111 of U-section, a transverse socket 112, a longitudinal channel 113 having two opposite slightly projected detents 114 on its inner surface, the channel 113 being adapted to pivotably secure to the upright 30 by driving a pivot 51 through lower apertures thereof and a lower through hole 301 of the upright 30 with the detents 114 matingly engaged with corresponding members (not shown) of the upright 30; and two leg members 12 each adapted to connect to the groove 111 and pivotably secured thereto by driving a pivot 51 through apertures thereof and an end through hole of the leg member 12.

[0021] The hollow cross member 20 compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com