Mini-Face Putter with Non-Horizontal Grooves

a putter and non-horizontal technology, applied in the field of golf putter heads and putter heads, can solve the problems of not providing grooves or allowing for variable weighting of the putter, lindsay does not disclose a golf putter, and is difficult to foresee the development of the putter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

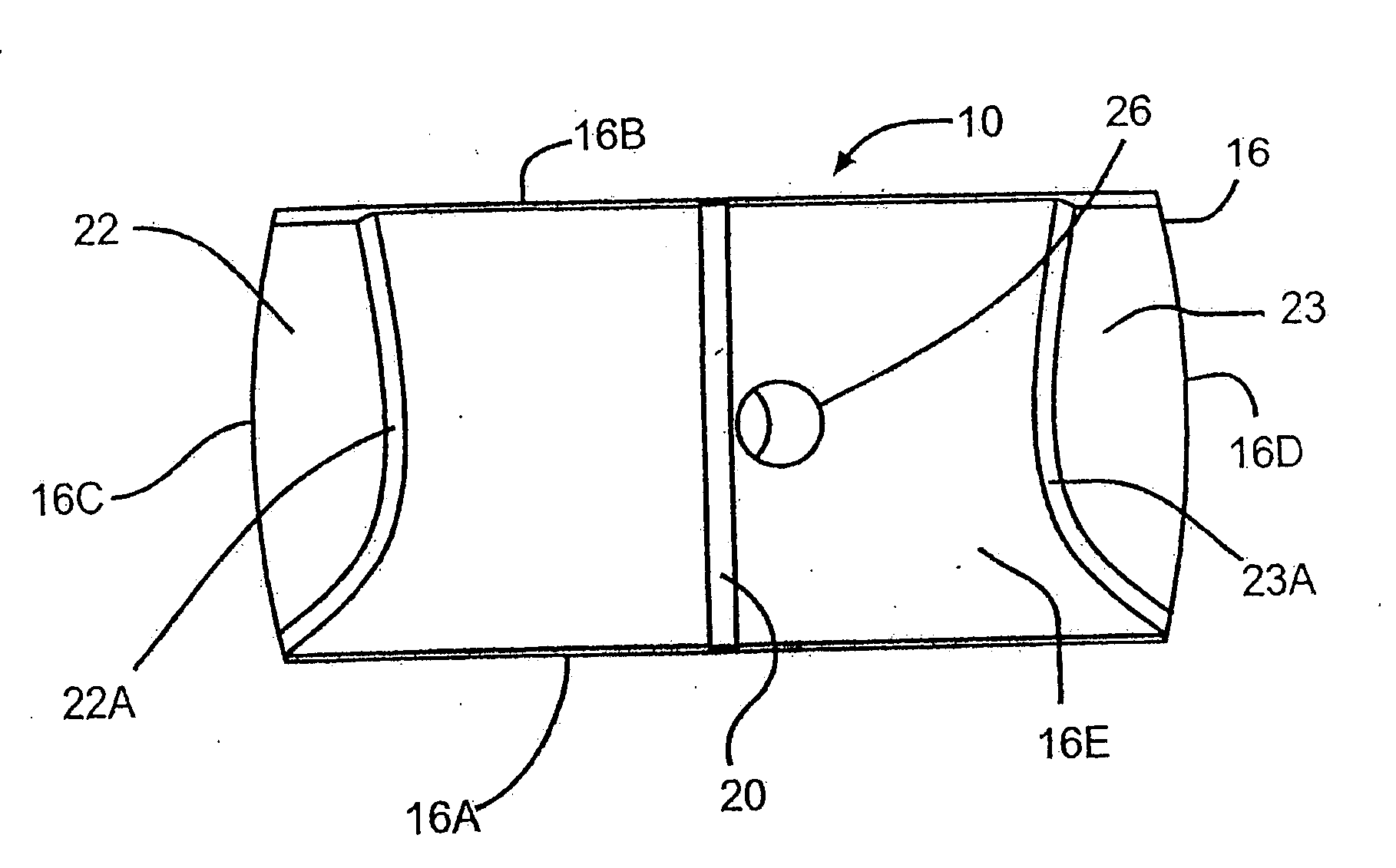

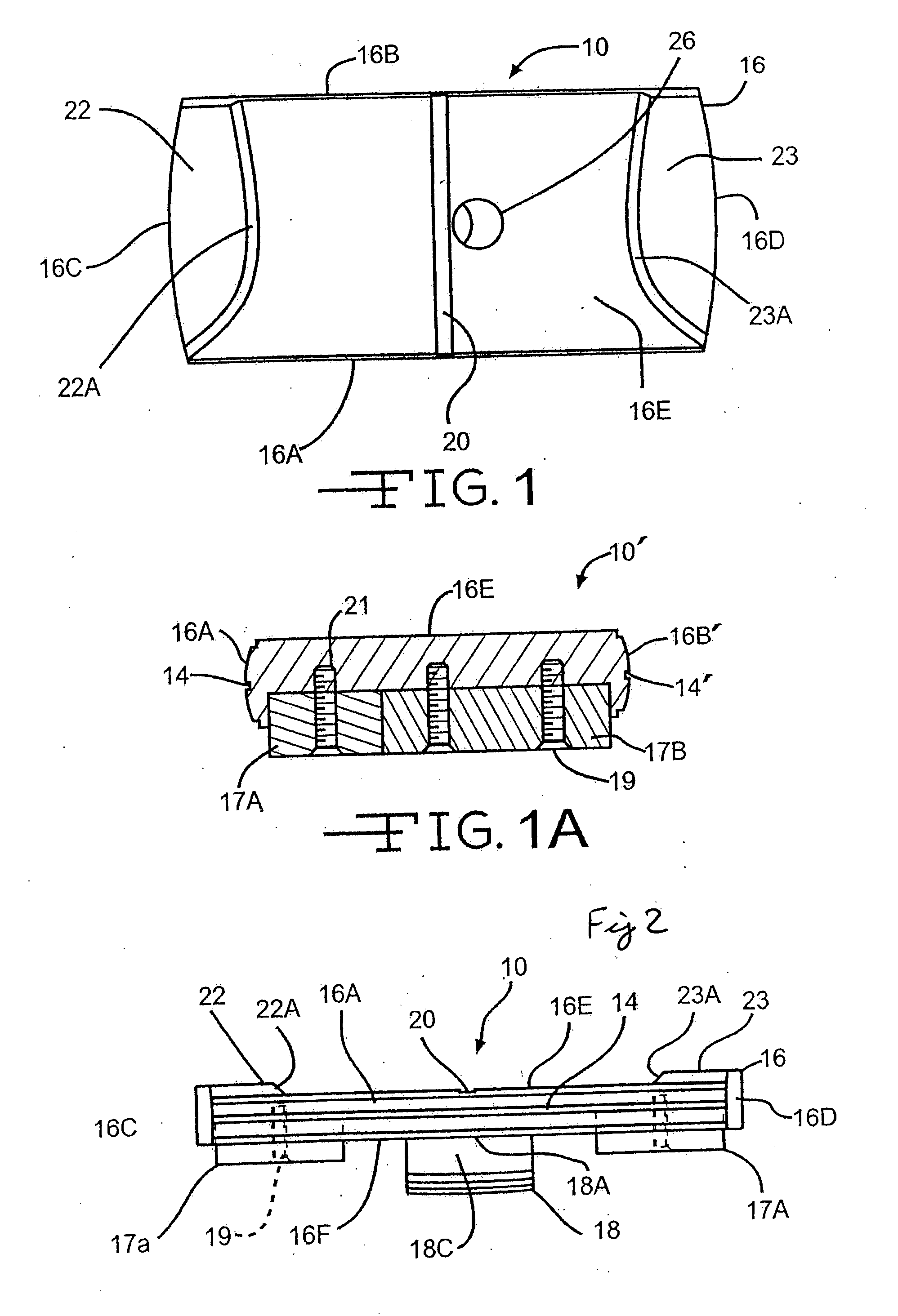

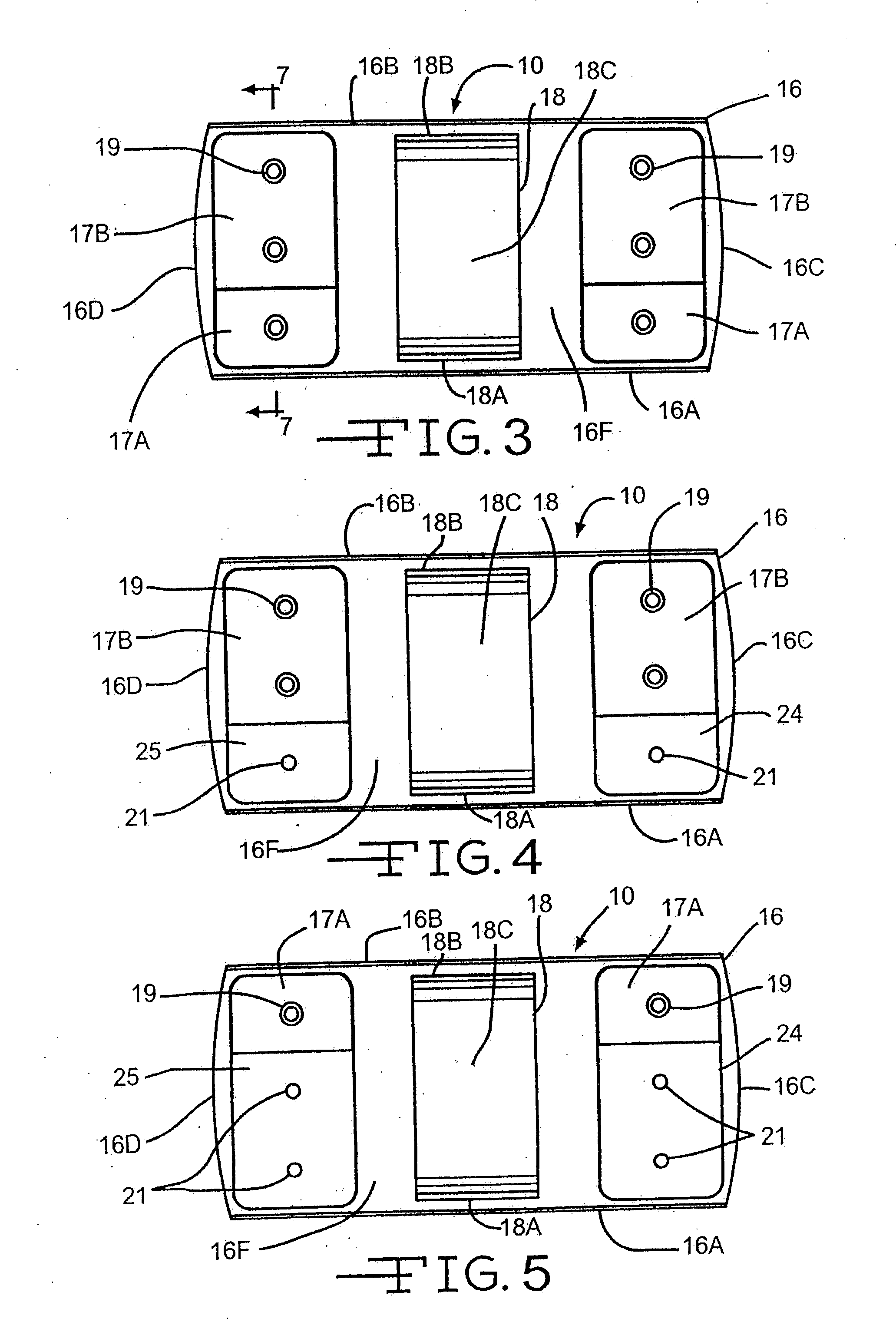

Image

Examples

example 1

[0146] The Sandwich #3 putter head 610 as illustrated in FIG. 30 through FIG. 36 was tested. The first independent test was on the rolled (rounded) face without a groove. The second was with a single groove as illustrated in the Figures. The Sandwich has two layers provided as top plate 620 and bottom plate 630. The bottom plate 630 of this putter head is brass, a heavier metal, and the top plate 620 of the putter head is aluminum, a lighter metal.

TABLE 1Testing data for the Sandwich #3 Putter Head 610.Skidface and groove configuration(inches)Putting Efficiency Indexrounded with only a seam:140.86rounded single groove140.87rounded three (3) grooves190.78

[0147] The first test showed surprisingly wide sweet spot which extends to ½ inch heel and toe from the center of the face. Contact at the center of face resulted in a Putter Efficiency Index of 0.857, the toe (contact near toe edge) resulted in a Putter Efficiency Index of 0.895 and the heel (contact near heel edge) resulted in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com