Wig and Method of Manufacturing the Same

a technology of wigs and wigs, applied in the field of wigs, can solve the problems of long work time, low productivity, difficult to achieve bulkiness, etc., and achieve the effect of easy manufacturing, excellent wigs, and easy tying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

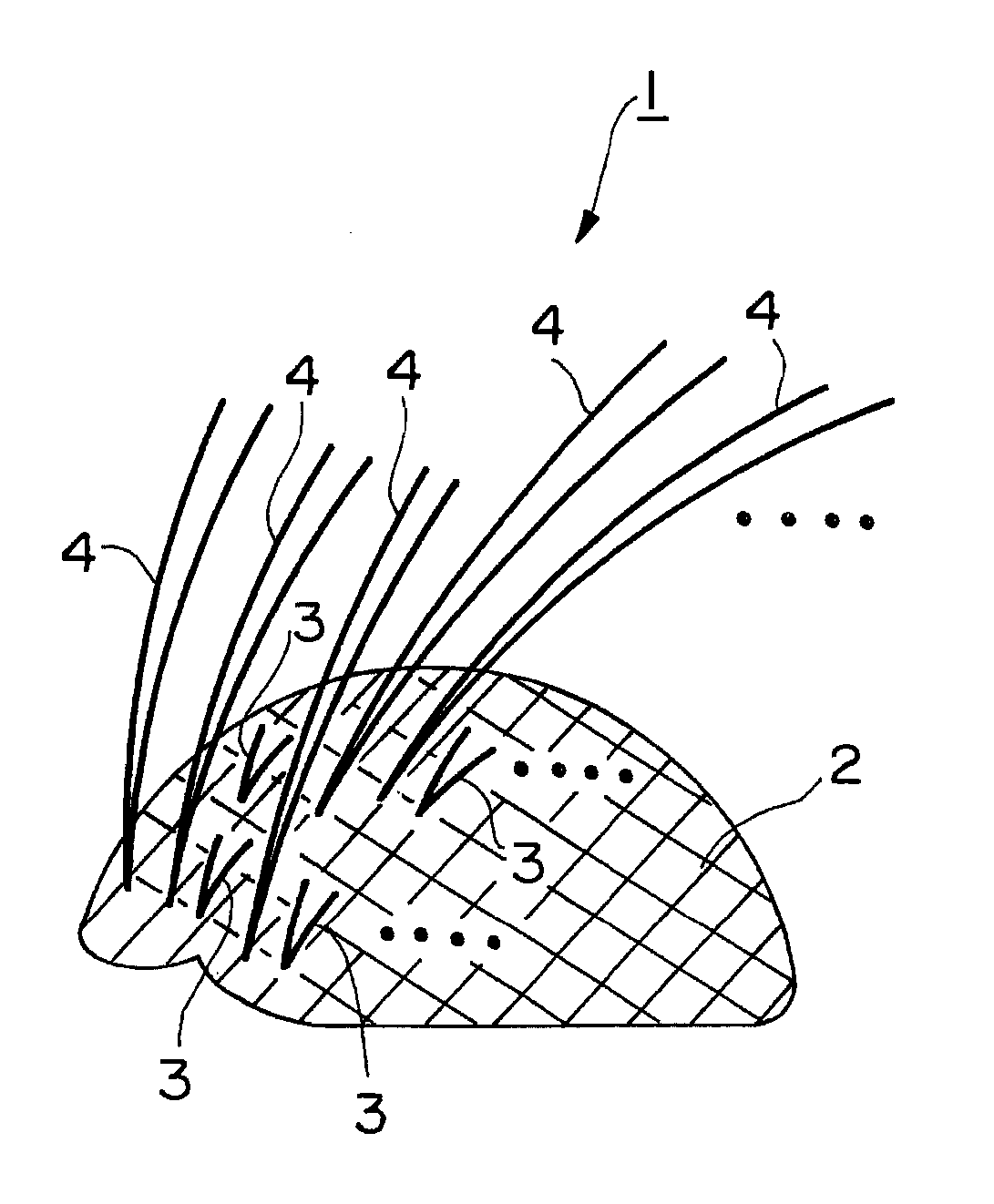

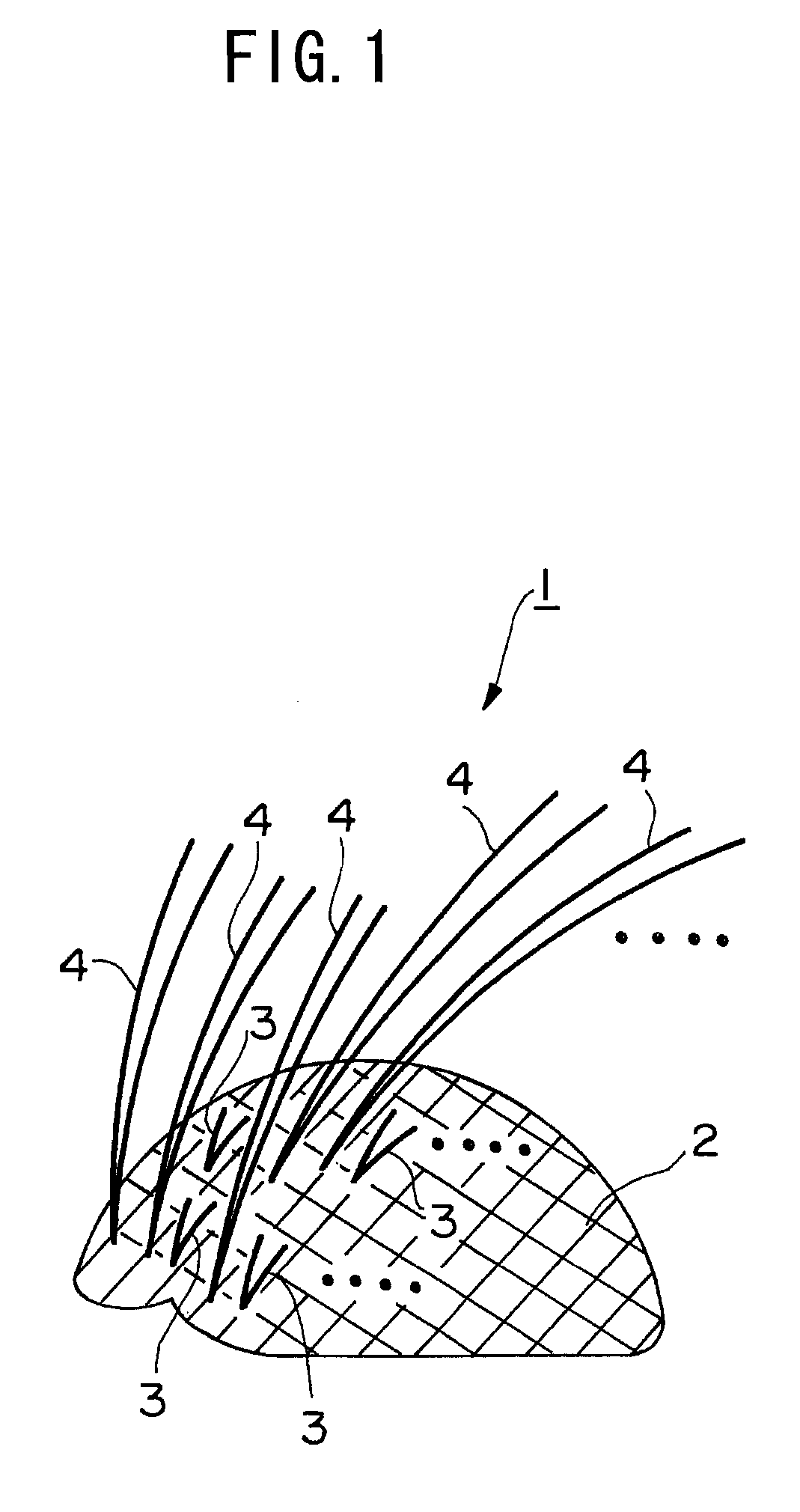

[0083] As Example 1, a wig 1 in accordance with the present invention was manufactured.

[0084] Utilizing a plaster pattern of the wig wearer's head shape prepared in advance, covering it with a net made of plastics such as nylon and polyester, coating thermosetting resin solution thereon, and heating to about 100° C., a net base 2 as a wig base was manufactured by molding to a curved shape as the head shape.

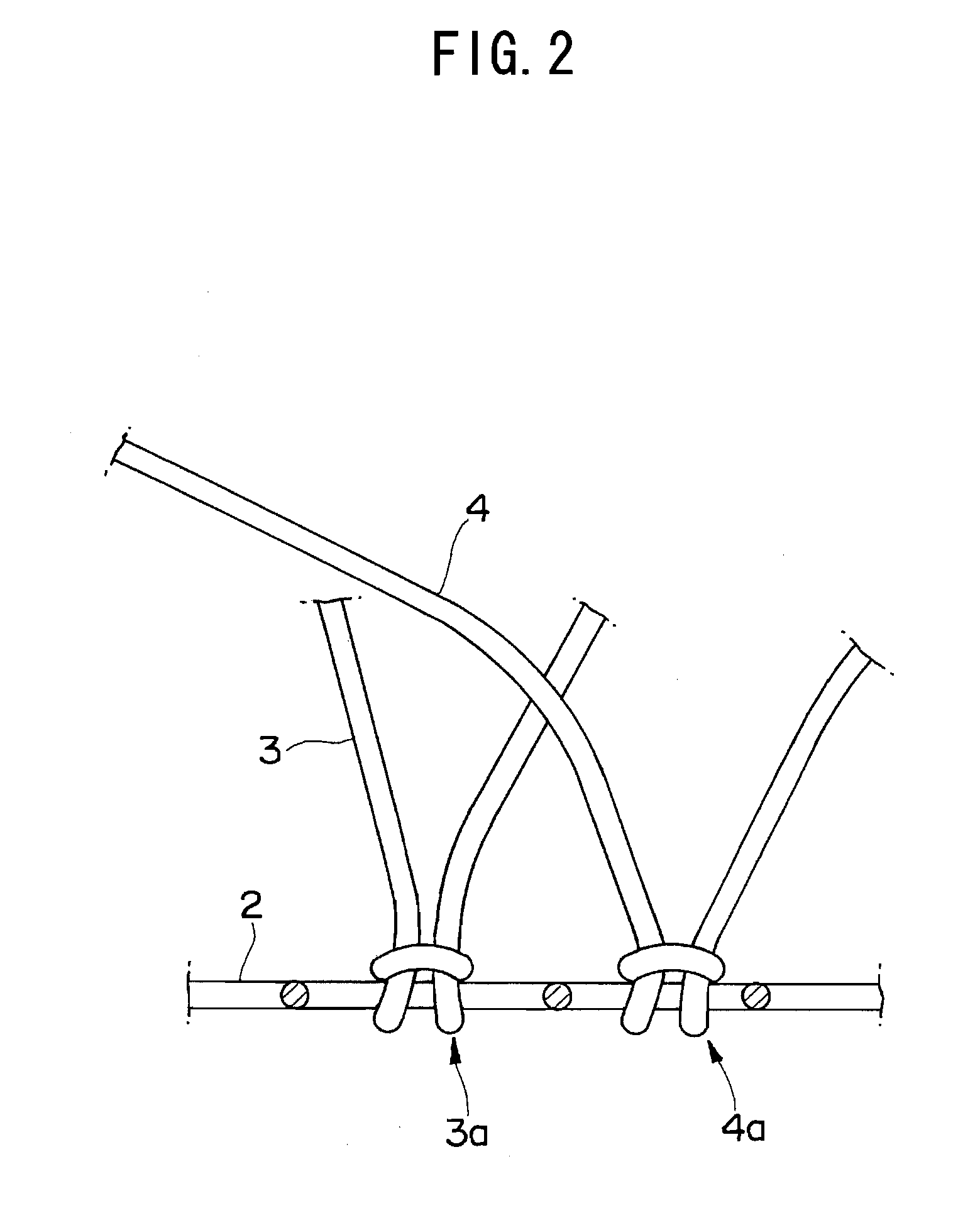

[0085] As the first step, curled hair 5 with a relatively small curl diameter of about 30 cm were tied to said net base 2 on matrix-like filaments of a net base 2 and at their cross sections. The hair 5 was tied by bending a strand to two at a center to form a pair, and by hooking their bent portions with a specific hooking needle to form knots 5a in the net base 2. The length of the hair 5 tied first was 15 cm, equal to that of long hair 4. Since the tied area of the net base 2 was 300 cm2, and the pre-determined density was 70%, the weight of 15 cm long hair was 50 g. Since al...

example 2

[0089] The same wig 1 as in Example 1 in accordance with the present invention was manufactured, except for the pre-determined ratio of short and long hairs 3 and 4 designed as 33% and 67%, respectively.

example 3

[0090] The same wig 1 as in Example 2 in accordance with the present invention was manufactured, except for dark brown as the color of short hair 3, and light brown as the color of long hair 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com