Moveable Armrest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

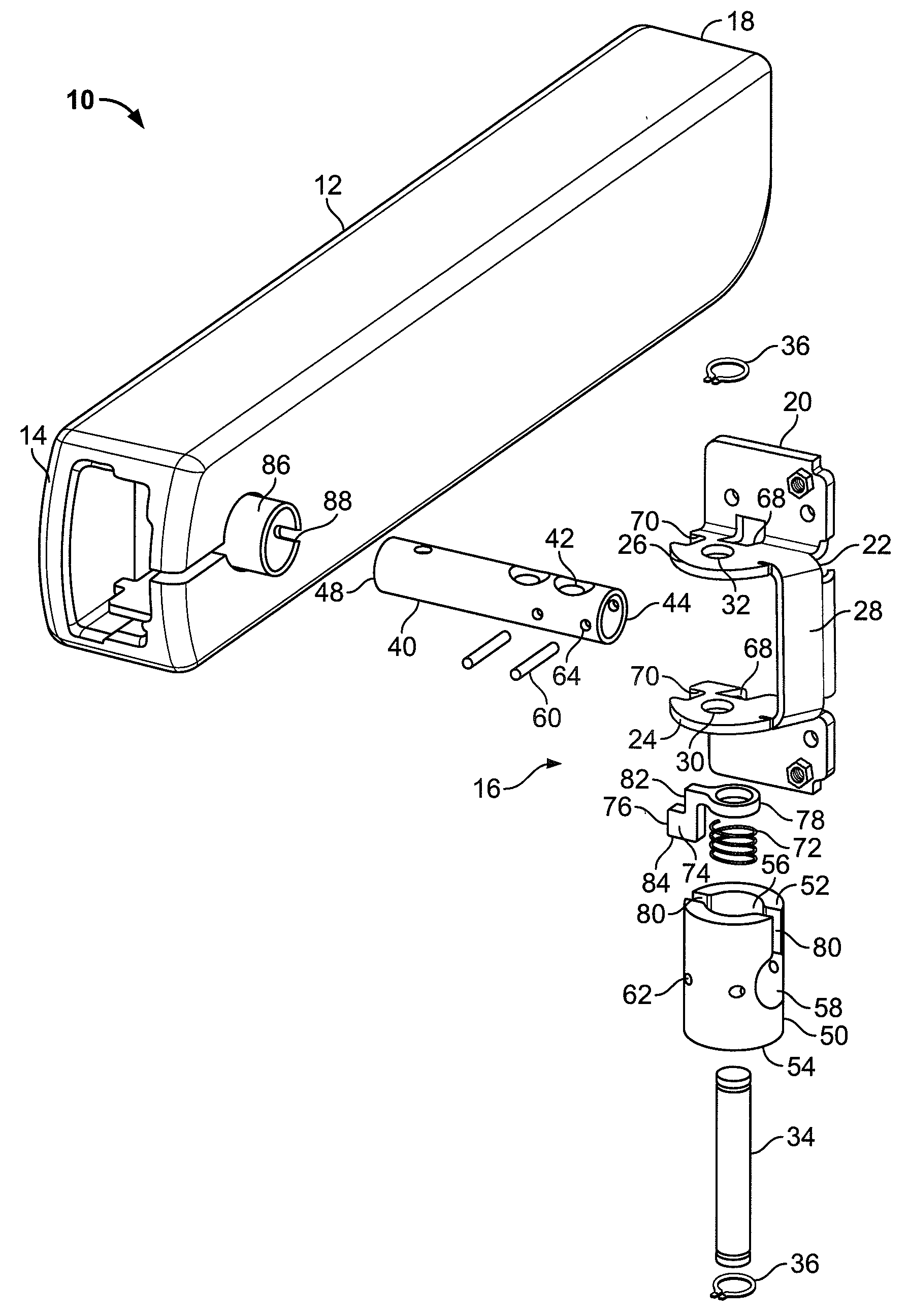

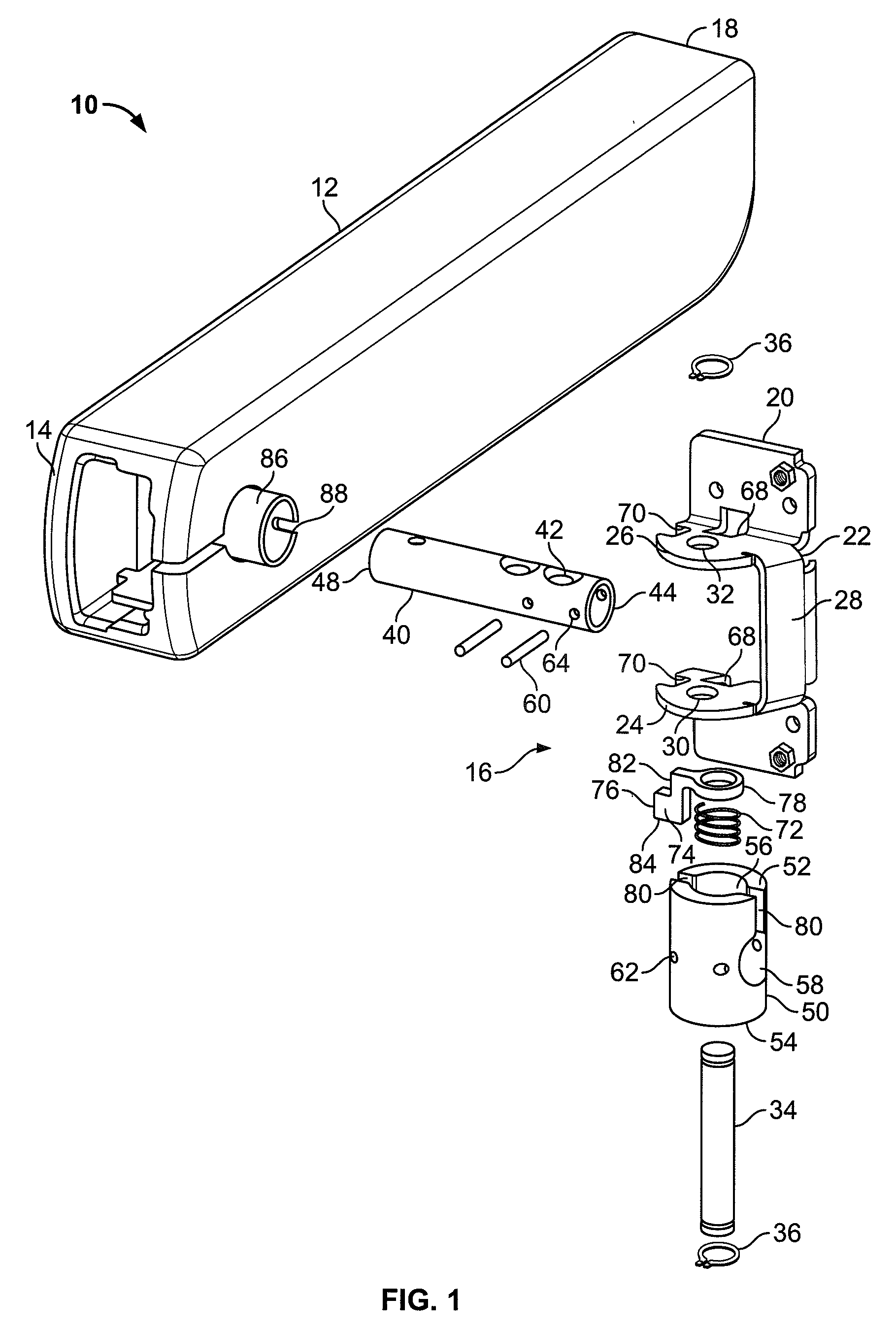

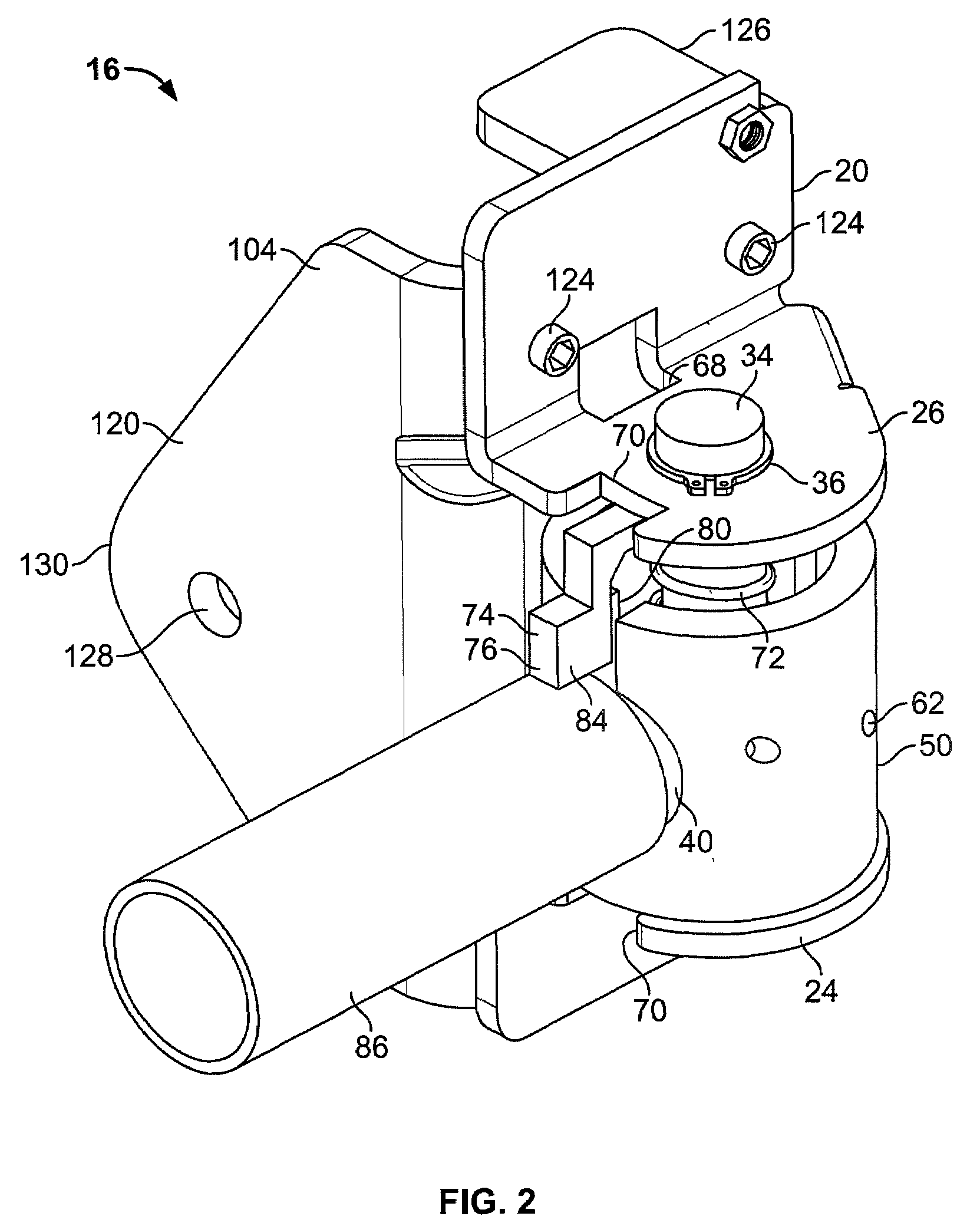

[0019]FIGS. 1-10 illustrate an armrest assembly 10 with an armrest 12 that moves from a “use” position, where the armrest extends generally horizontally along side of a seat for use by the occupant, to a “stowed” position, where the armrest is behind the seat to maximize pass-through room between adjacent seats. The armrest assembly 10 enables four simple movements, including about two pivot axes, to move the armrest 12 between the use position and the stowed position. For example, with respect to moving from the use position to the stowed position, the armrest 12 is (1) pivoted about a horizontal axis to an upright orientation, (2) raised vertically to operate the locking mechanism, (3) pivoted about a vertical axis to locate it behind the backrest of the seat, and then (4) lowered vertically to operate the locking mechanism. The locking mechanism restrains movement of the armrest 12 to prevent unintended movement of the assembly 10 when in the use and stowed positions.

[0020]With r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com