Shock-absorbing facemask attachment assembly

a technology of attachment assembly and face mask, which is applied in the field of attachment assembly, can solve the problems of little, if any, shock absorption of conventional face mask mountings, and the presence of face masks in umpire masks and other helmets that include facemasks, and neither the design of conventional facemask mounts nor the materials used in conventional facemask mounts provide much impact absorption. , to achieve the effect of greatly improving shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

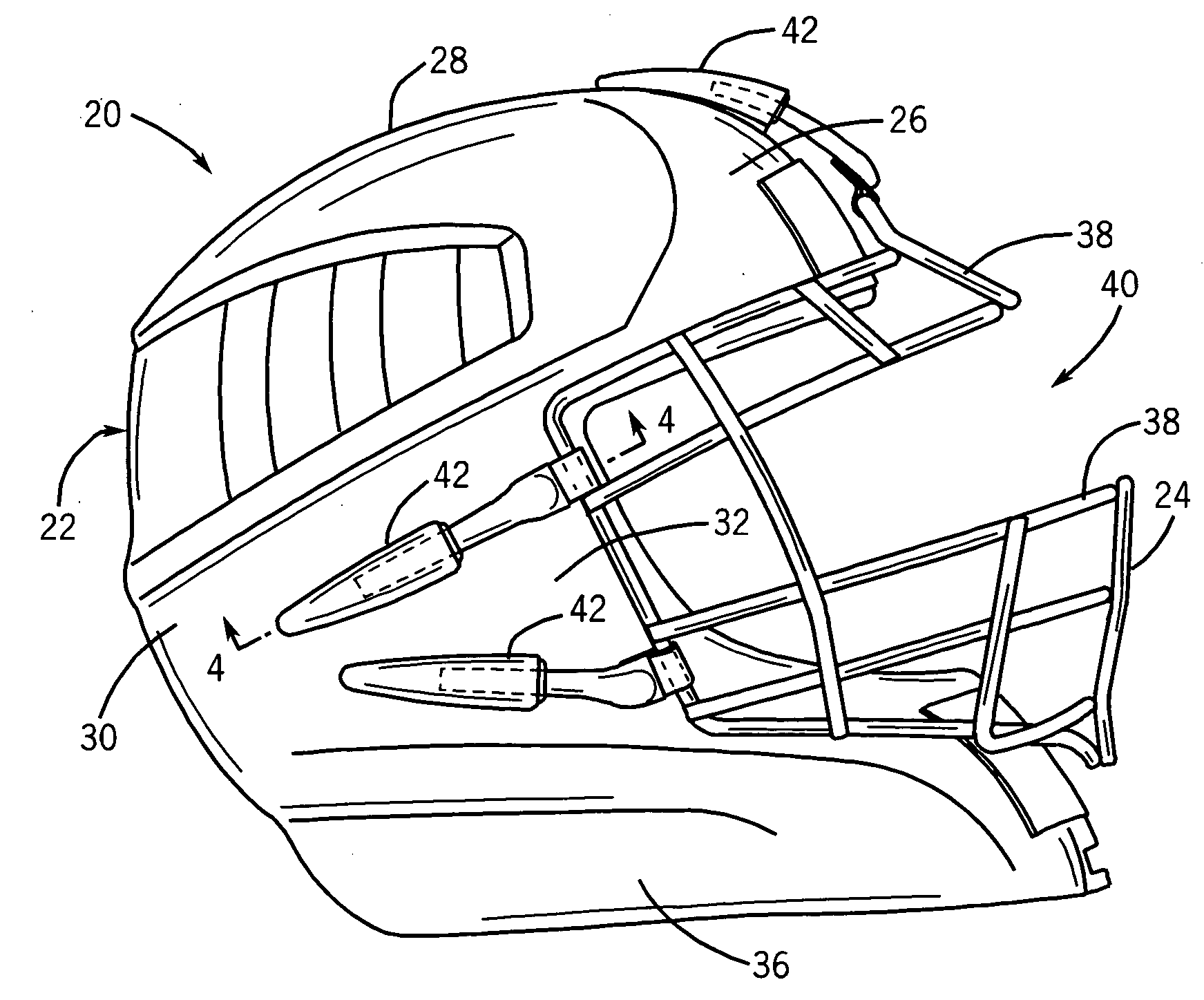

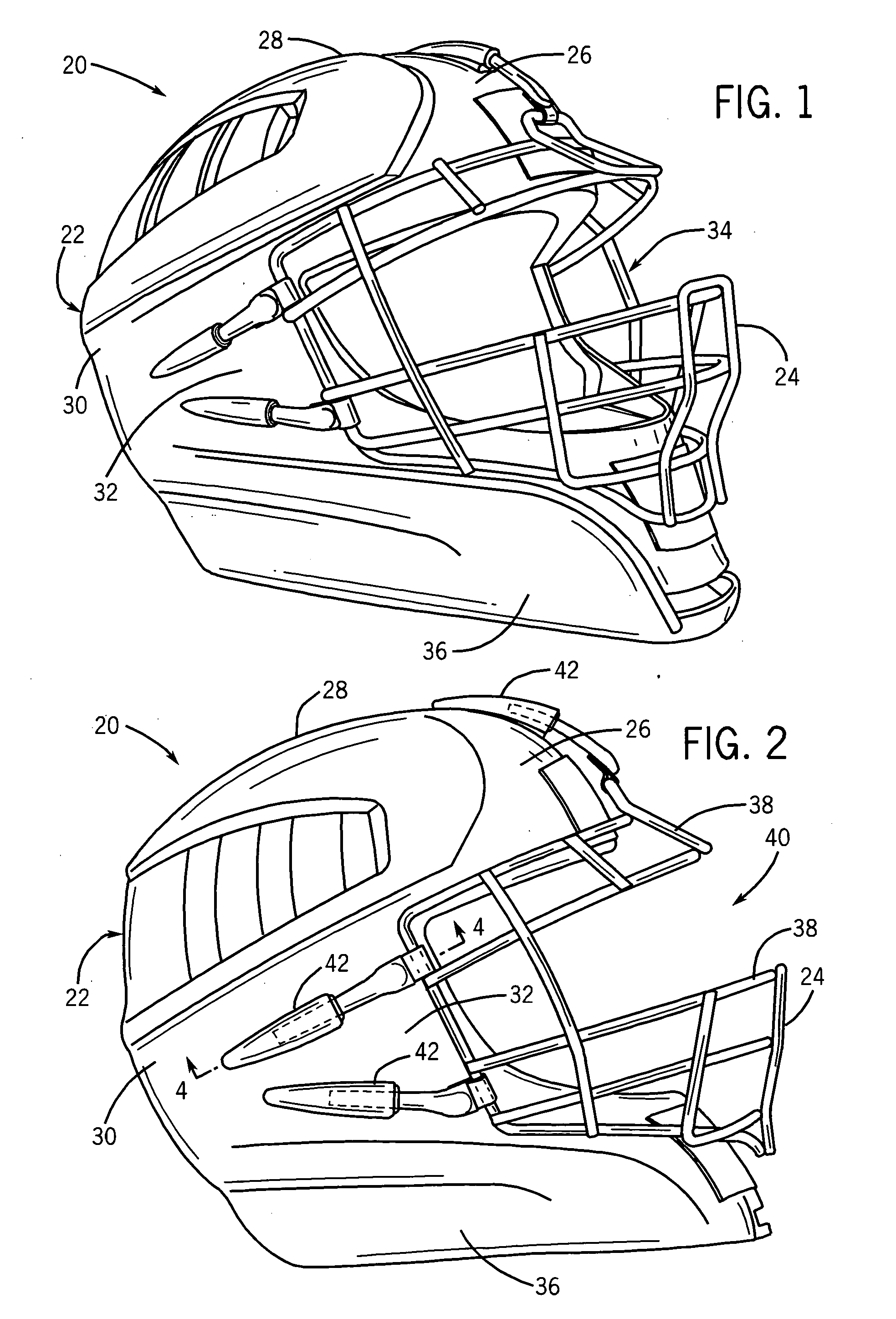

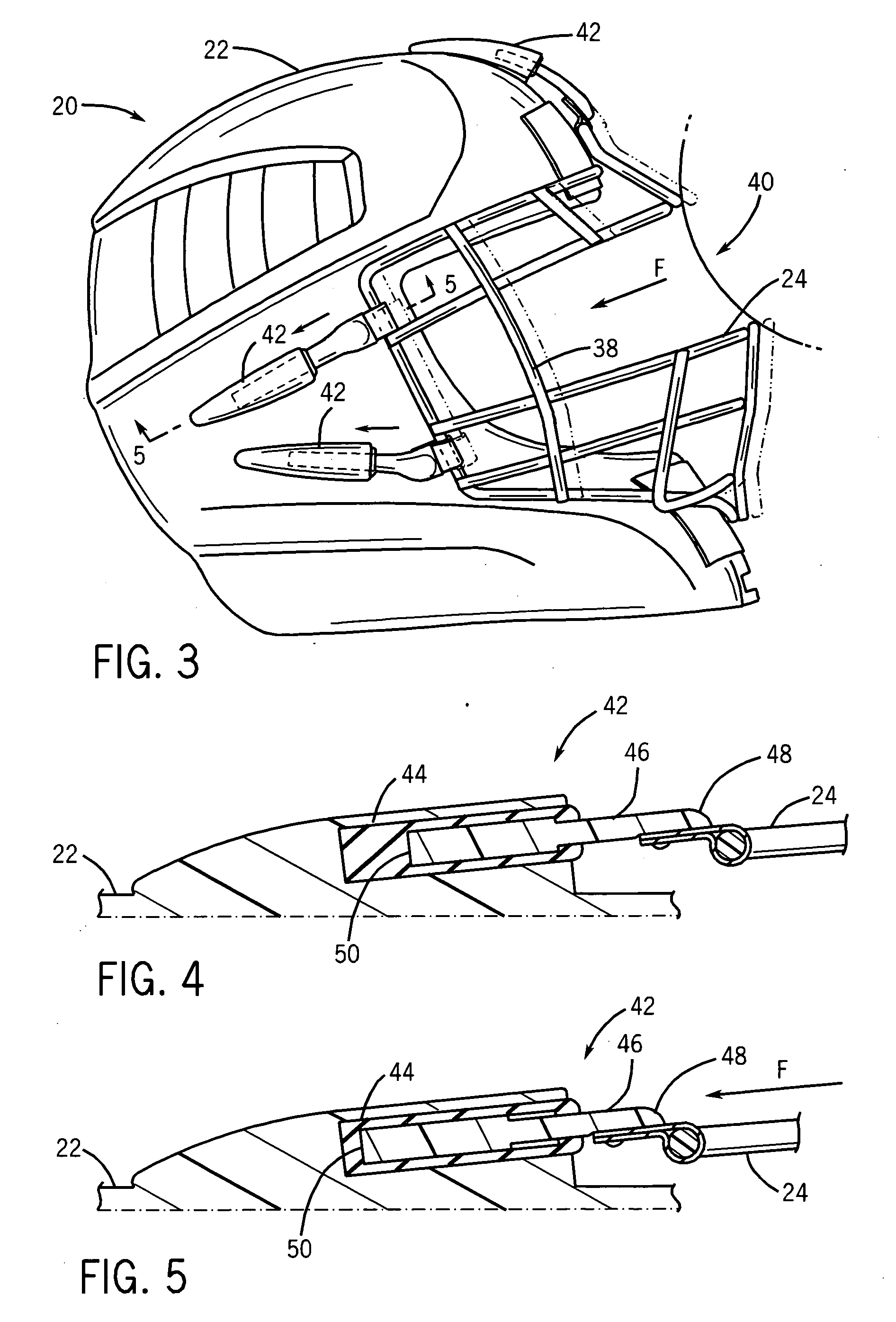

[0028]Referring to FIGS. 1 and 2, a helmet having a shock-absorbing facemask attachment assembly is indicated generally at 20. The helmet 20 of FIG. 1 is configured as a catcher's helmet; however, the invention can also be applied to other types of helmets, such as, for example, an umpire's helmet and / or mask, a lacrosse helmet, a football helmet, a hockey helmet, and practically any other type of helmet that includes a facemask. The helmet includes a shell 22, a padding assembly (or head support assembly) (not shown), and a facemask 24.

[0029]The shell 22 is a generally hemispherically-shaped head covering, which forms a cranial cavity 26 configured to generally cover and protect the upper portion of a user's head. The shell 22 has a dome-like crown 28, a generally continuous circumferential side wall 30, first and second ear protective regions 32 and 34, and a neck protective region 36 that surrounds a wearer's neck. Preferably, the crown 28, side wall 30, first and second ear prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com