Mudflap Retainer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

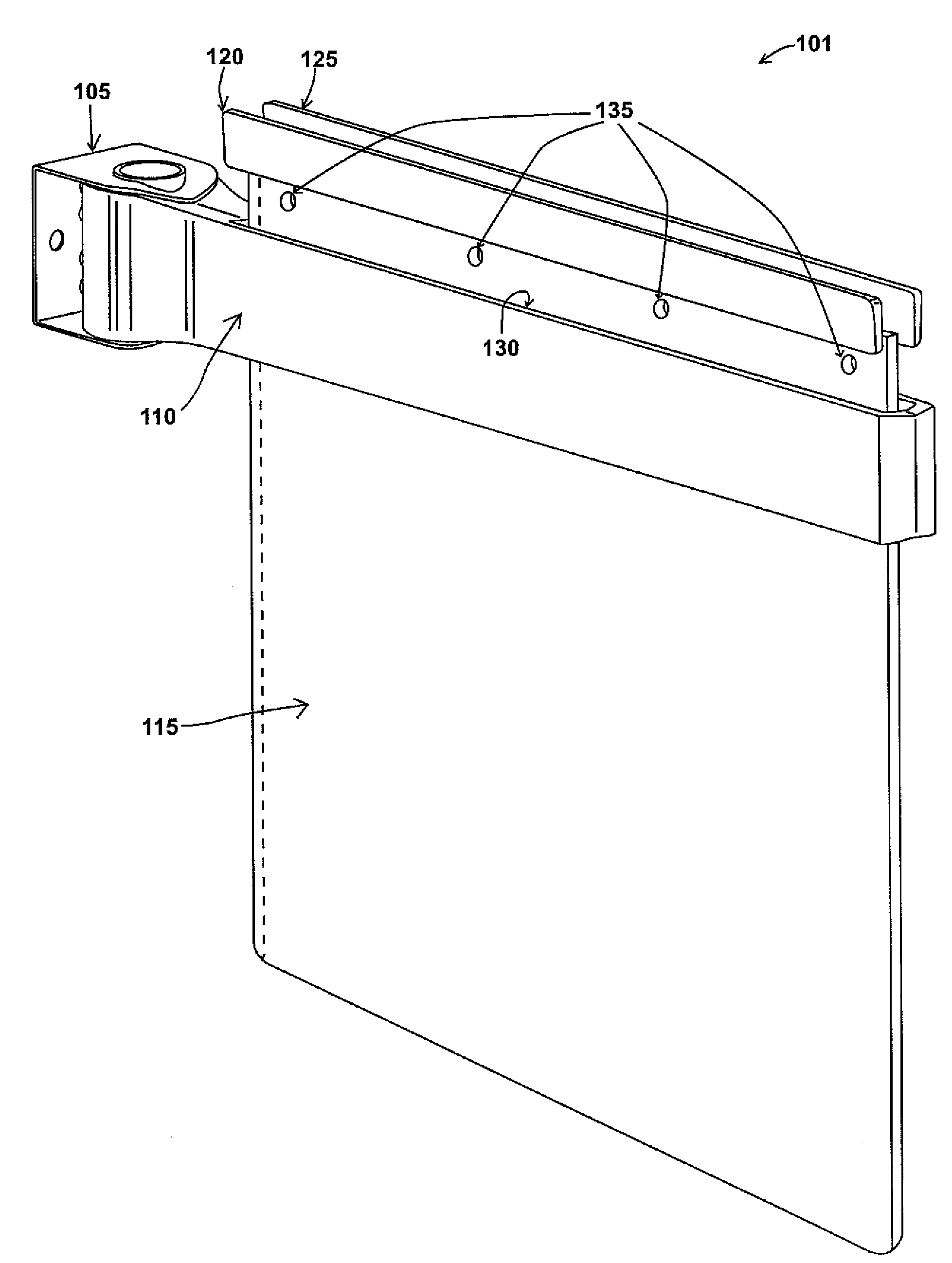

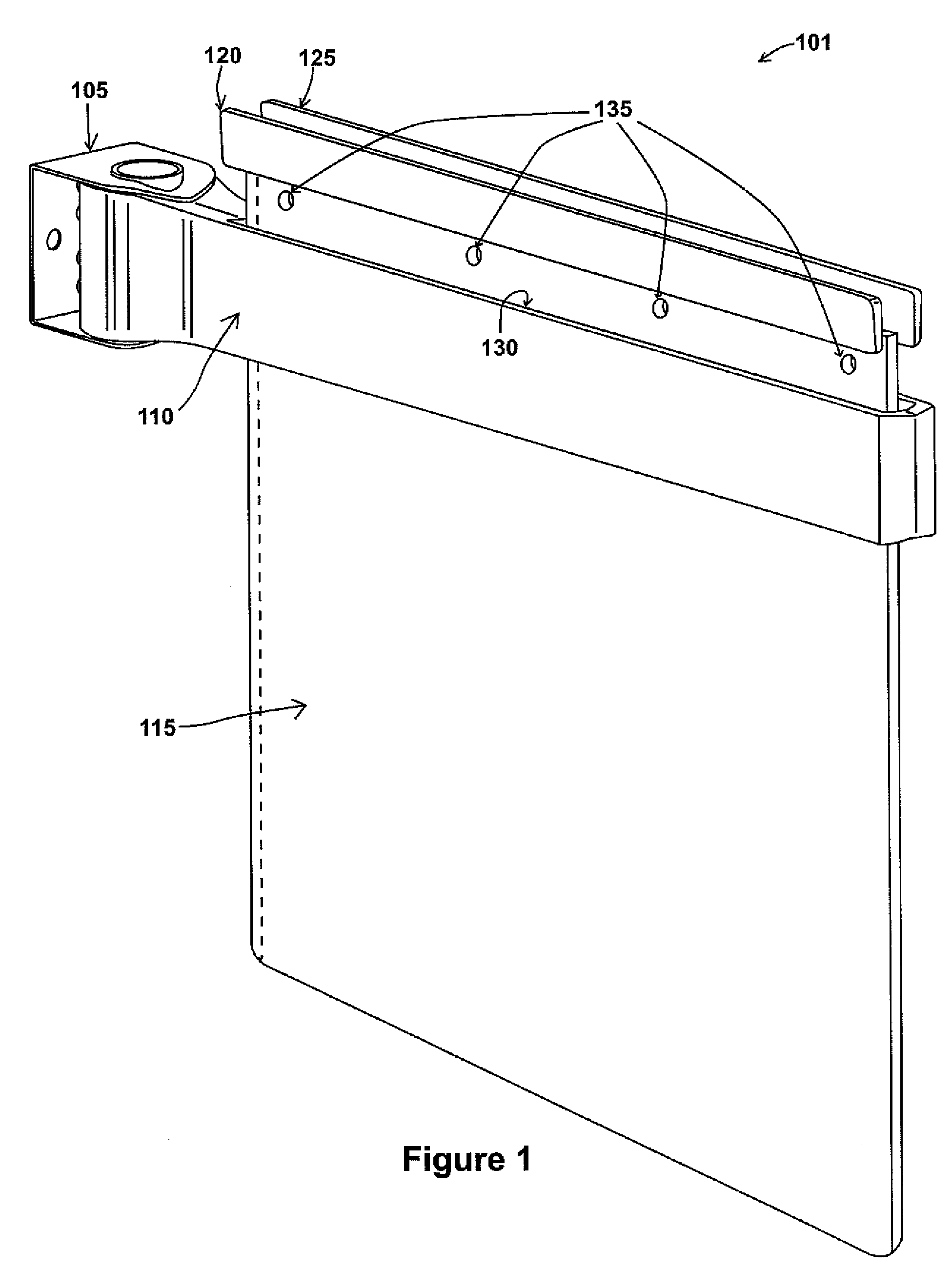

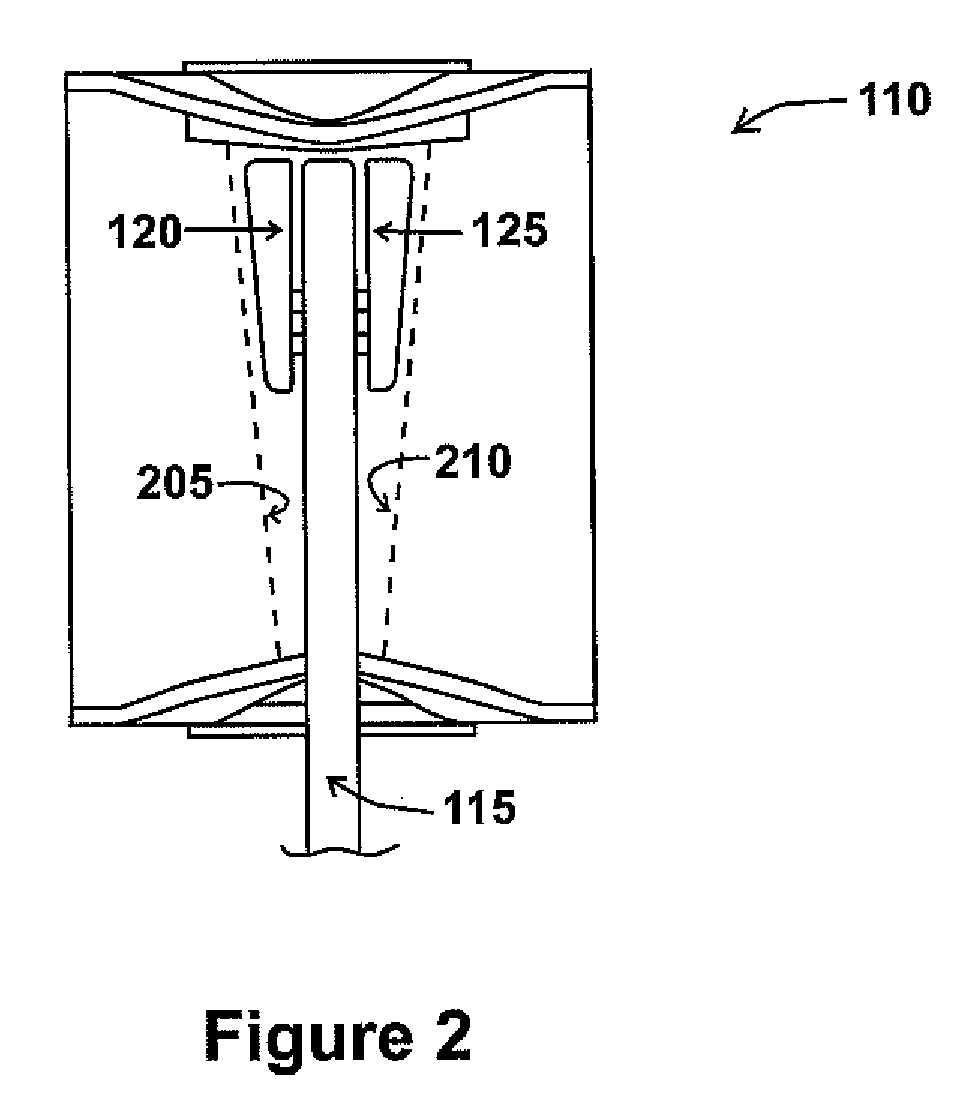

[0015]The various embodiments of the present disclosure and their advantages are best understood by referring to FIGS. 1 through 5 of the drawings. The elements of the drawings are not necessarily to scale, emphasis instead being placed upon clearly illustrating the principles of the disclosure. Throughout the drawings, like numerals are used for like and corresponding parts of the various drawings.

[0016]Referring now to FIG. 1, a mudflap assembly 101 comprises a bracket 105, a hanger 110, a mudflap 115, and two mudflap retainers 120, 125. The bracket 105 attaches to a vehicle (not shown) behind its wheel (not shown). A hanger 110 couples to the bracket 105 and extends away from the vehicle (not shown) in order to retain a mudflap 115 in a position to deflect flying debris (not shown). The mudflap 115 is coupled to the hanger 110 by two retainers 120, 125, wherein each retainer has a plurality of protrusions (FIGS. 3, 4, 5) which extend through the holes 135 of the mudflap 115. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com