Car wash roller

a technology for washing rollers and cars, applied in the direction of transportation and packaging, rope railways, train hauling devices, etc., can solve the problems of increasing the cost of car wash operators, difficult to manufacture rollers, and reducing the effectiveness, durability and life of the roller system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

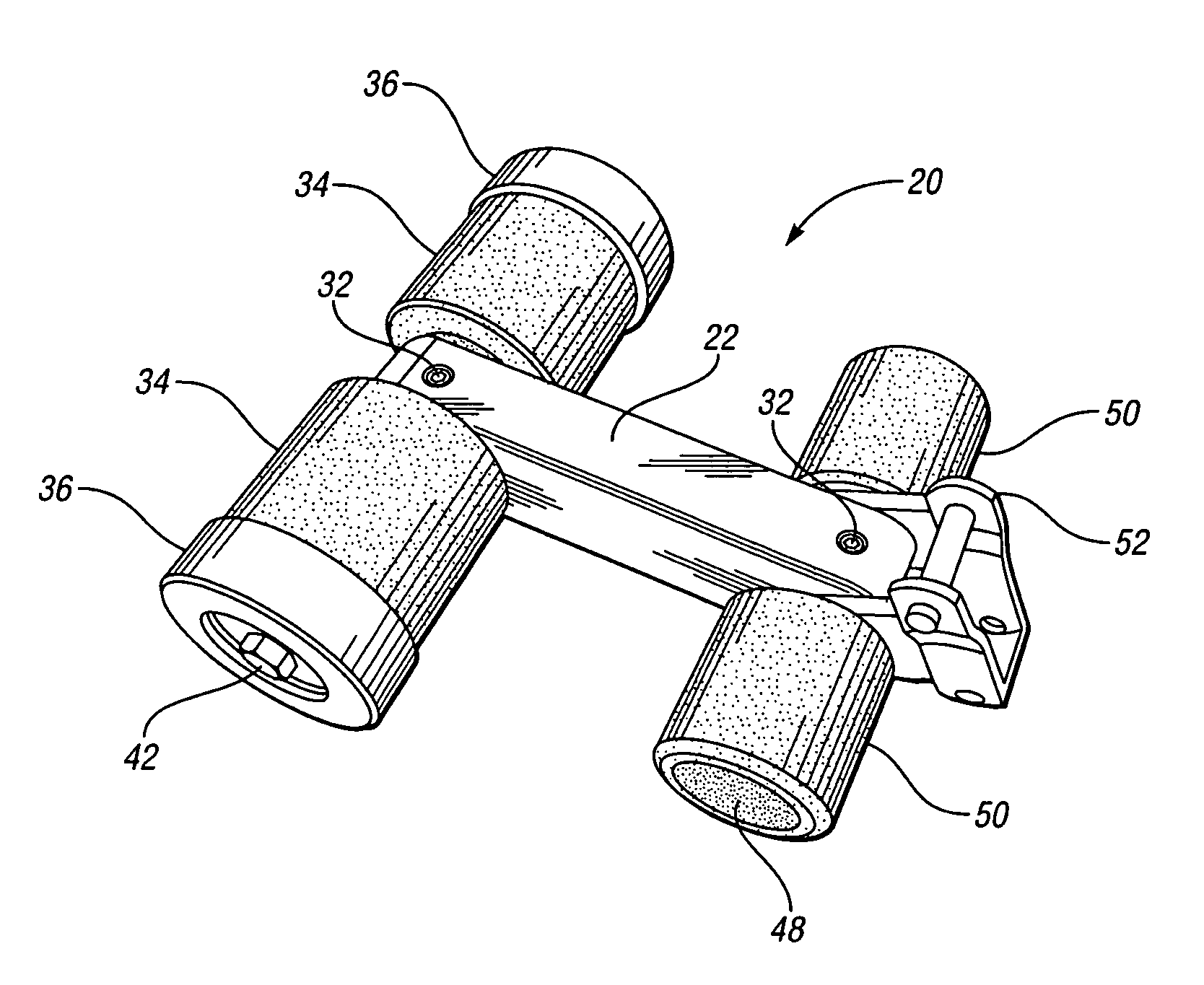

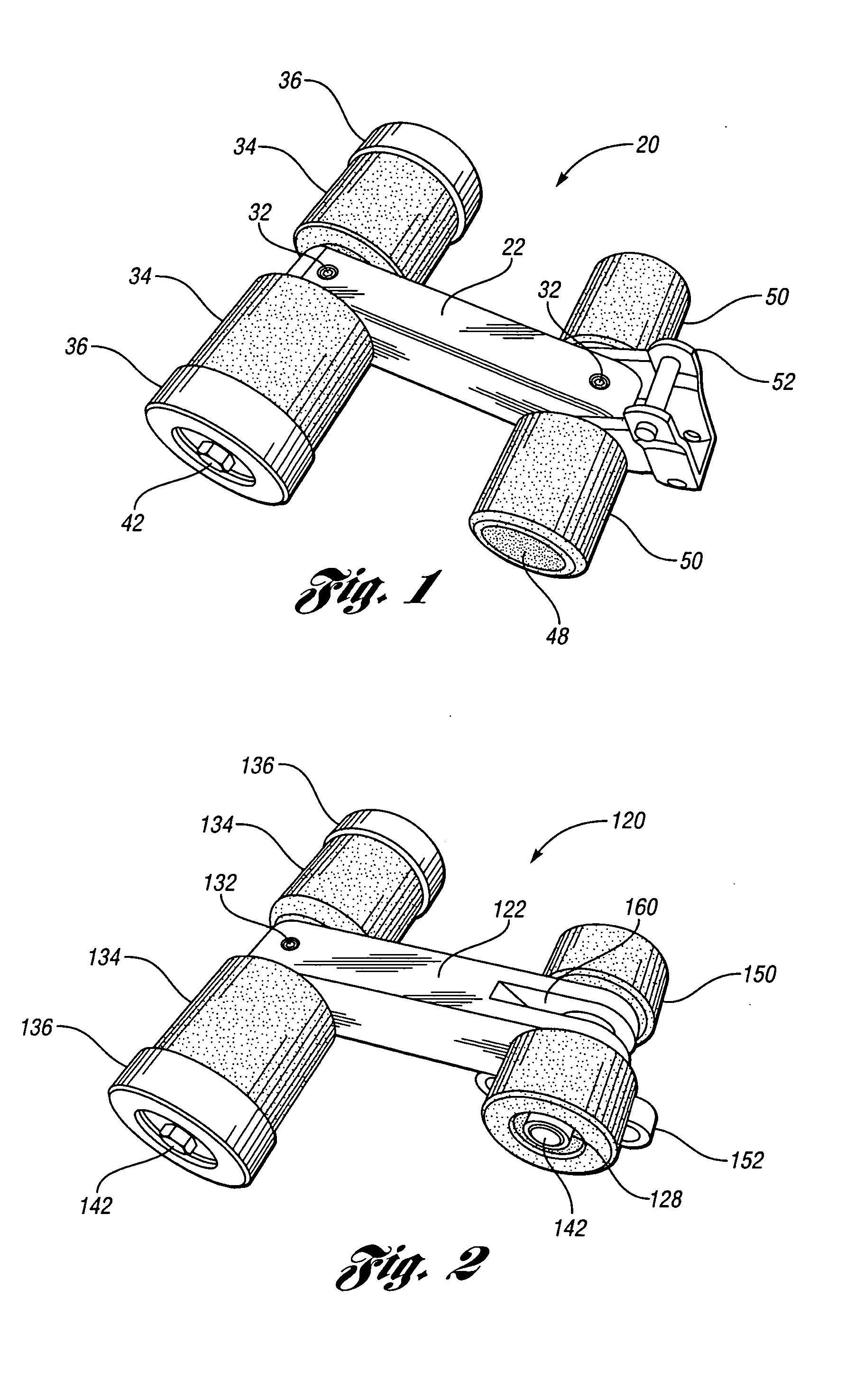

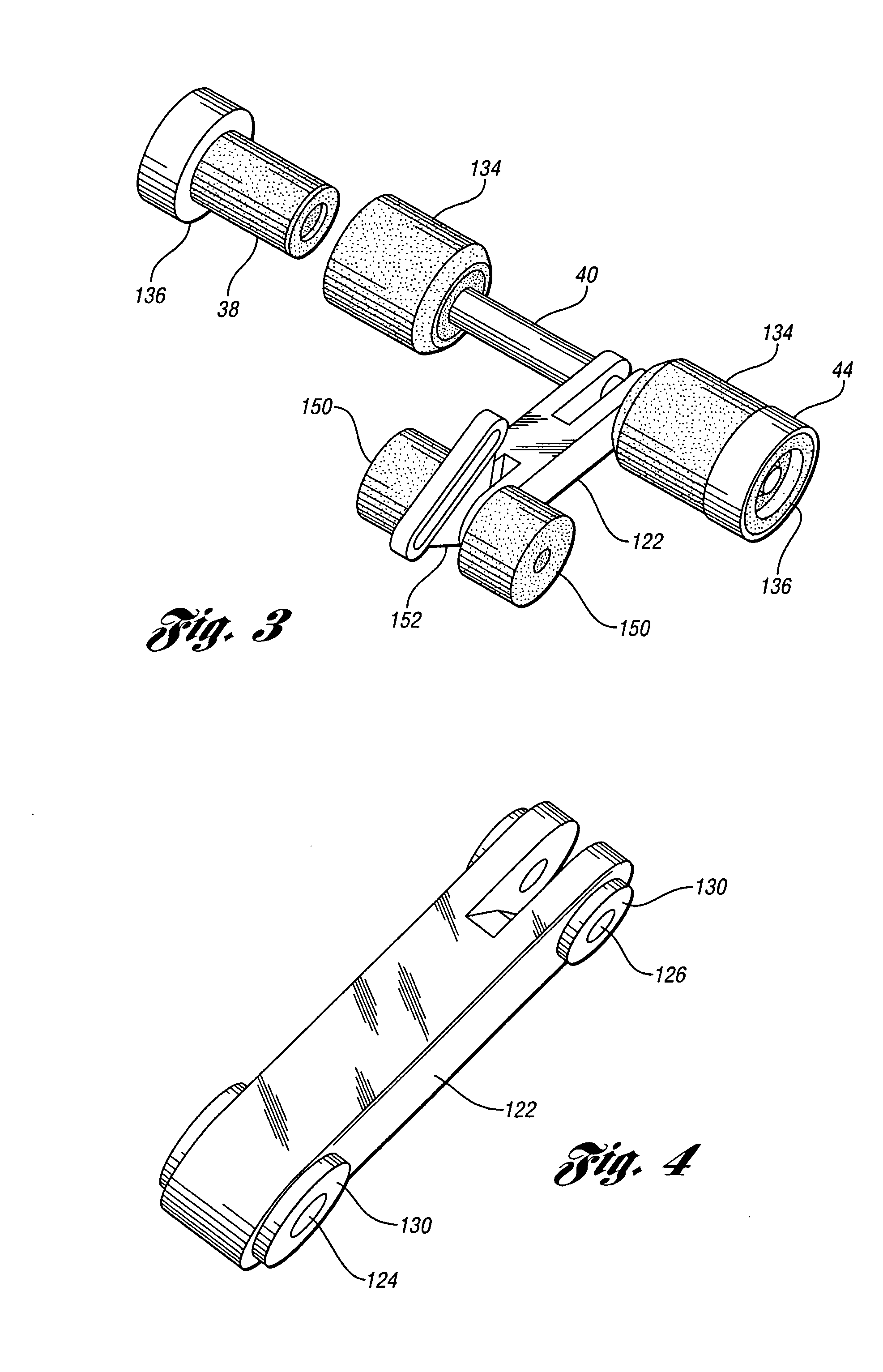

[0019]Referring to the drawings, FIGS. 1-13 show contemplated embodiments of a conveyorized car wash roller 20 according to the present invention. The car wash roller 20 can be used in any know conveyorized car wash system that includes a conveyor system for pushing or pulling an automatic vehicle through an automatic car wash system. It should be noted that the embodiments shown show two contemplated embodiments of the conveyorized car wash roller 20 according to the present invention however other contemplated embodiments exist but are not shown in the figures.

[0020]FIG. 1 shows the conveyorized car wash roller 20 according to one embodiment thereof. The car wash roller 20 includes a car wash roller body 22 that generally has a rectangular shape with a predetermined width and length. One embodiment of the present invention has a width of approximately 1-½ inches. It should be further noted that approximately 1.5 inches of plastic is generally adjacent to the shafts of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com