Paver hopper flap suspension system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

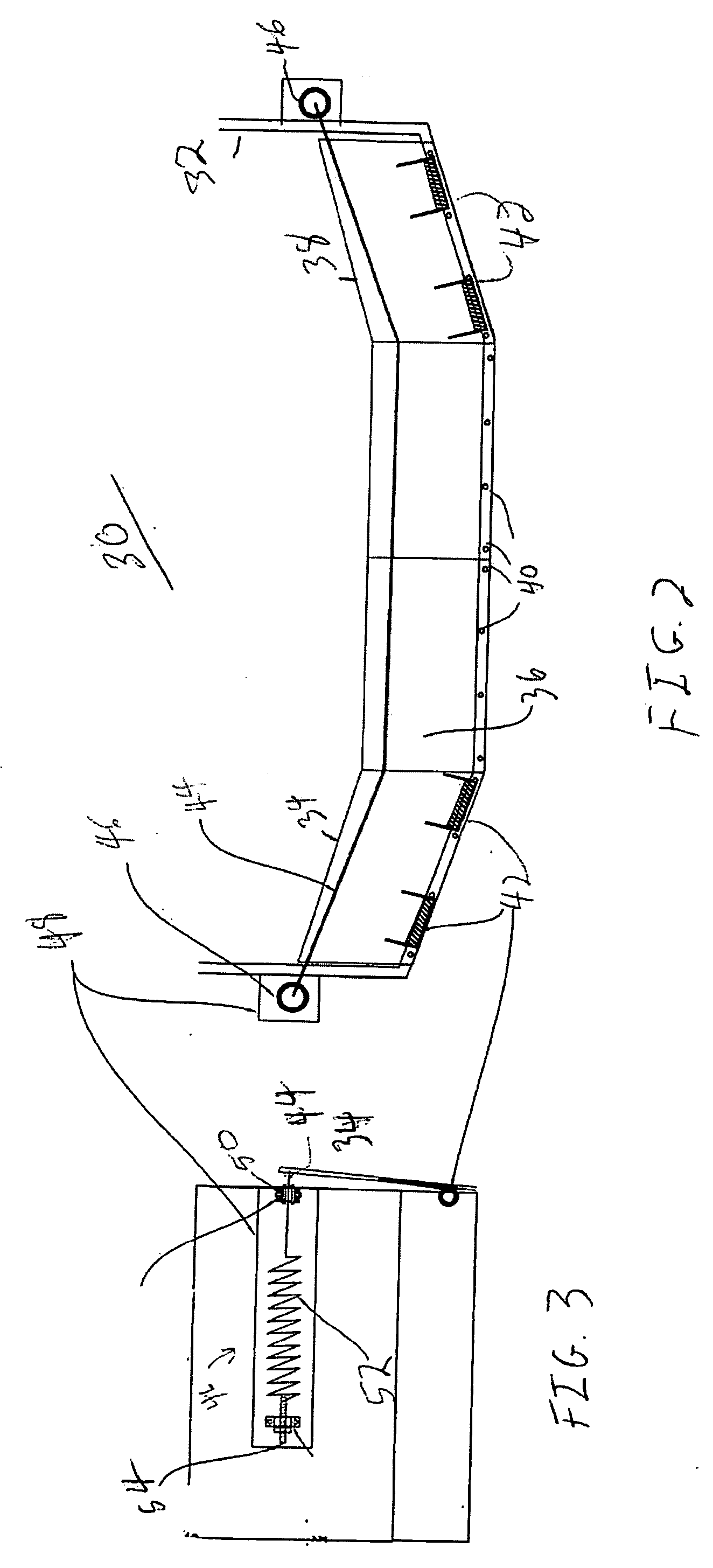

[0012]The paver hopper flap suspension system of the present invention has a number of flaps attached to the hopper frame. A cable restraint line is attached to the flaps. A tensioning system is attached to the cable restraint line. The tensioning system allows the flaps to distort as the loading truck body engages the hopper entrance. Once the truck exits the hopper entrance the hopper flap suspension system causes the flaps to spring back to their original shape. The suspension system may include a torsion spring biasing the flaps into a vertical position. The tensioning system may include a tension adjuster. Using this system the flaps are not torn and hold the asphalt in place as the loading trucks dump asphalt into the hopper.

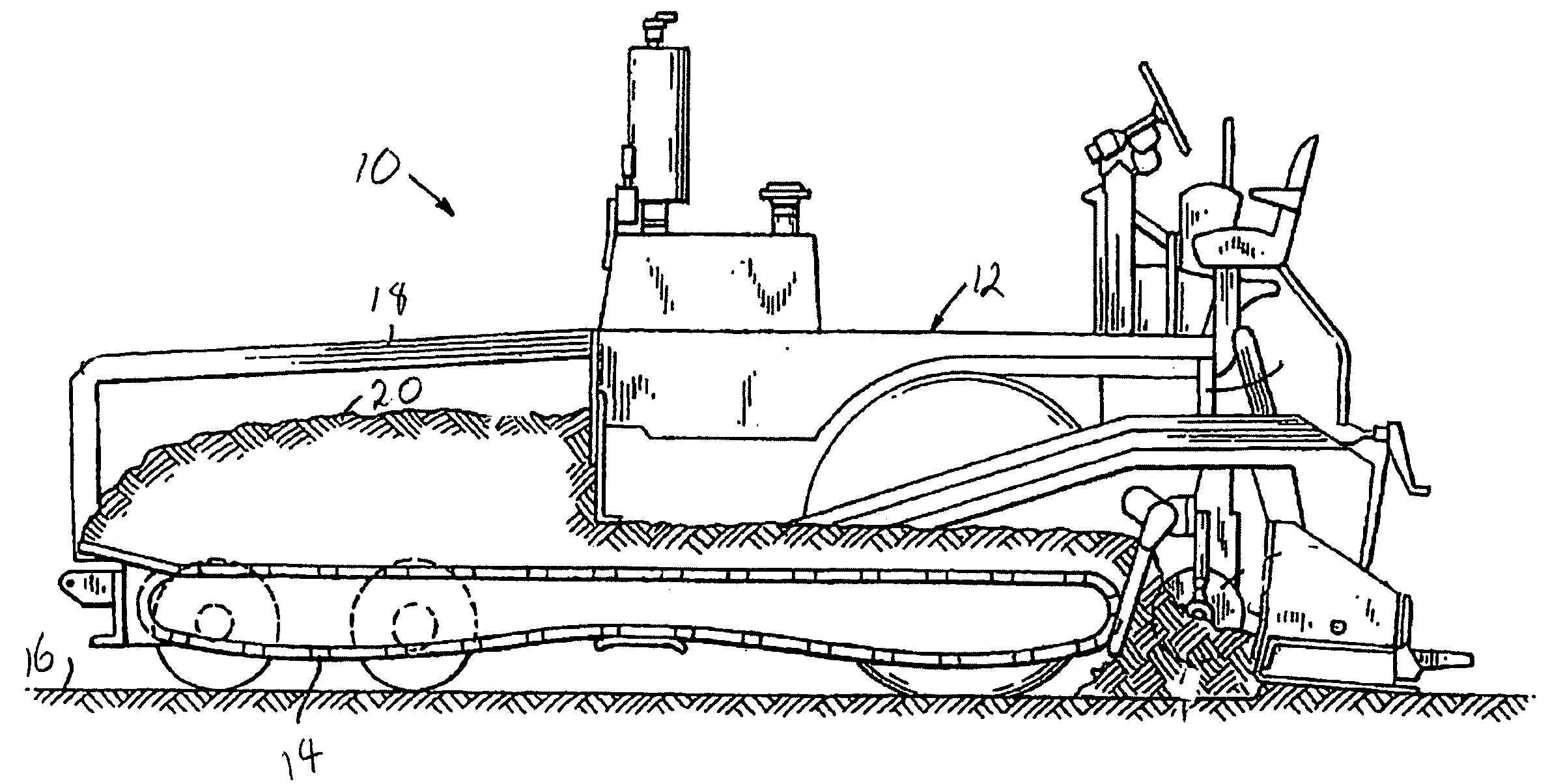

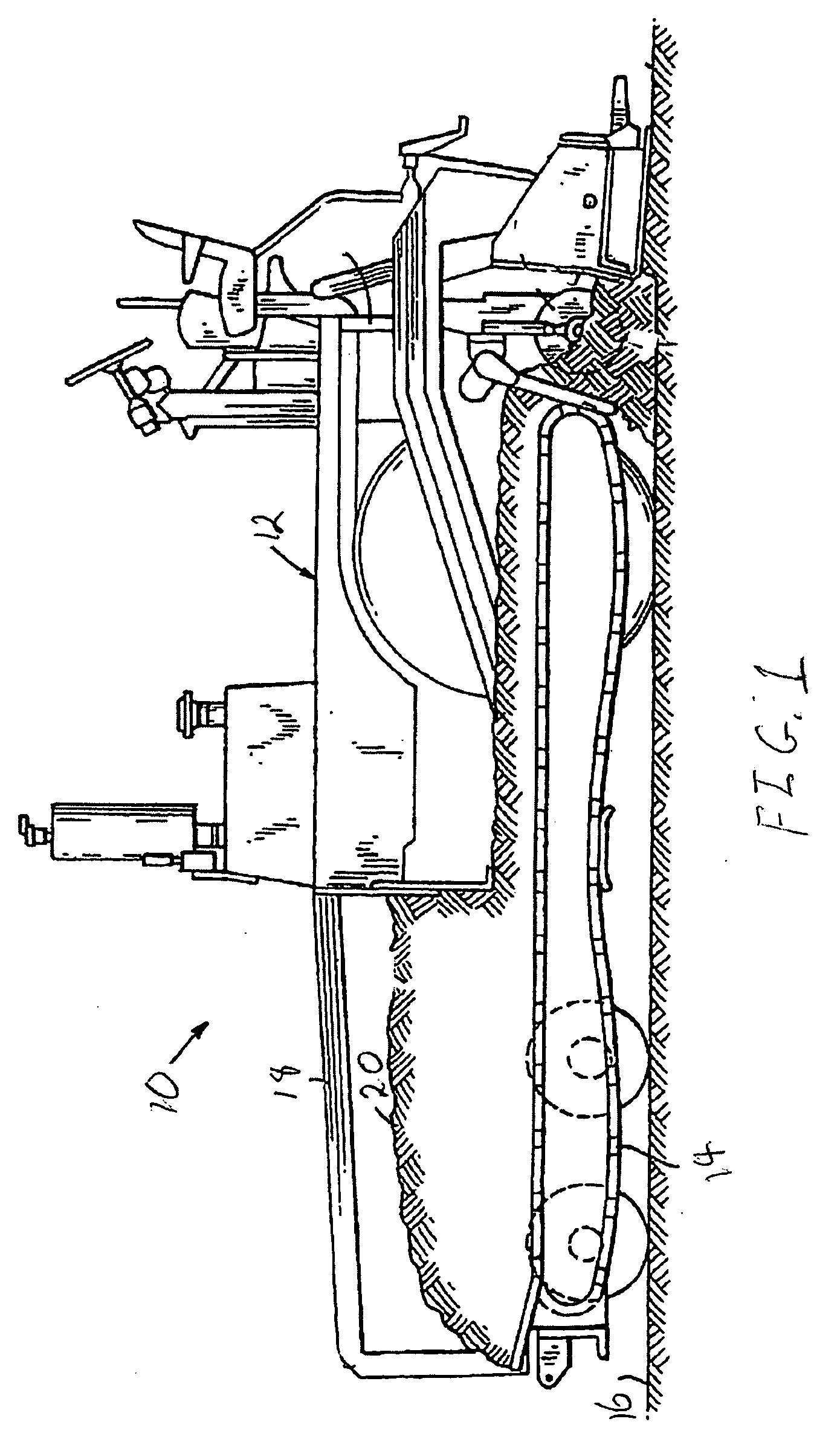

[0013]FIG. 1 is a side view of a paver 10 in accordance with one embodiment of the invention. The paver 10 has a chassis 12 that moves on tracked wheels 14 over the ground 16. A hopper 18 is attached to the chassis 12. The hopper 18 holds the asphalt 20. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com