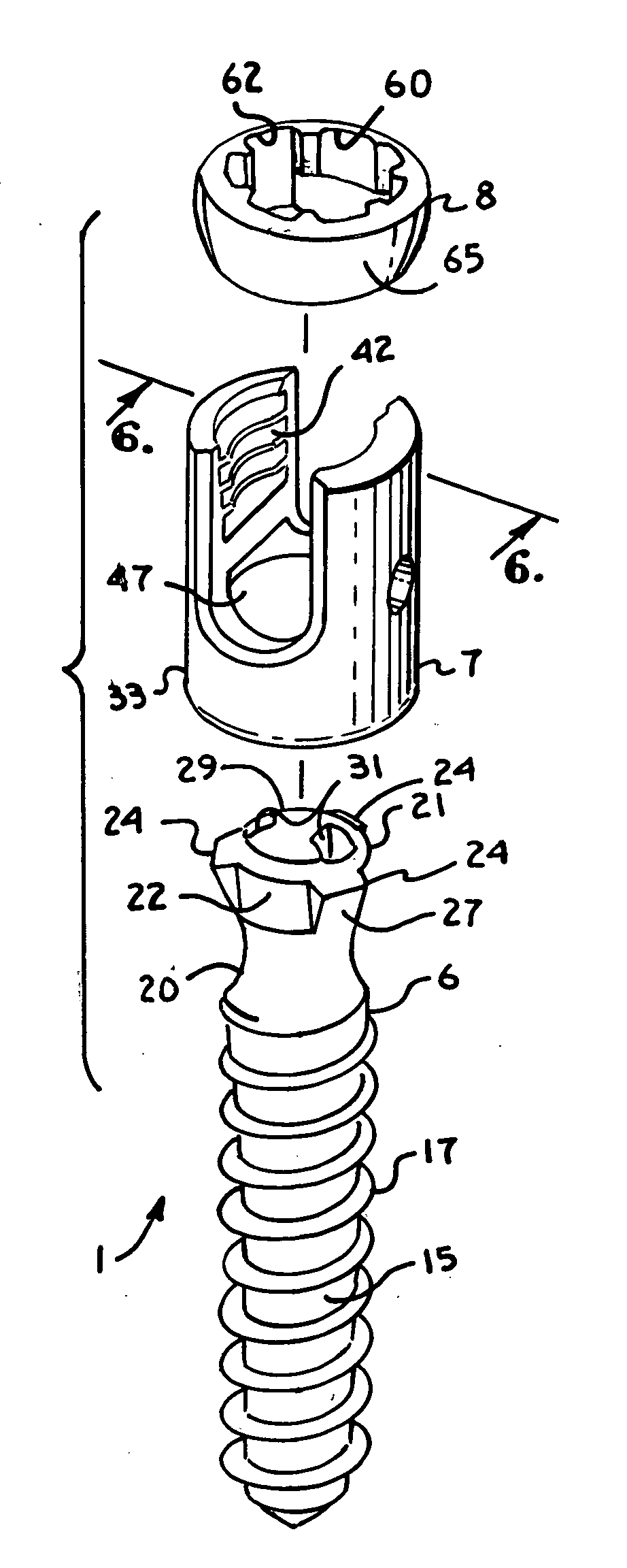

Upload shank swivel head bone screw spinal implant

a bone screw and head technology, applied in the field of polyaxial bone screws, can solve the problems of difficult or impossible to do, undesirable movement of implant parts within the body, and difficulty in transferring parts, so as to improve mechanical properties, prevent further rotation, and reduce the height of the screw head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

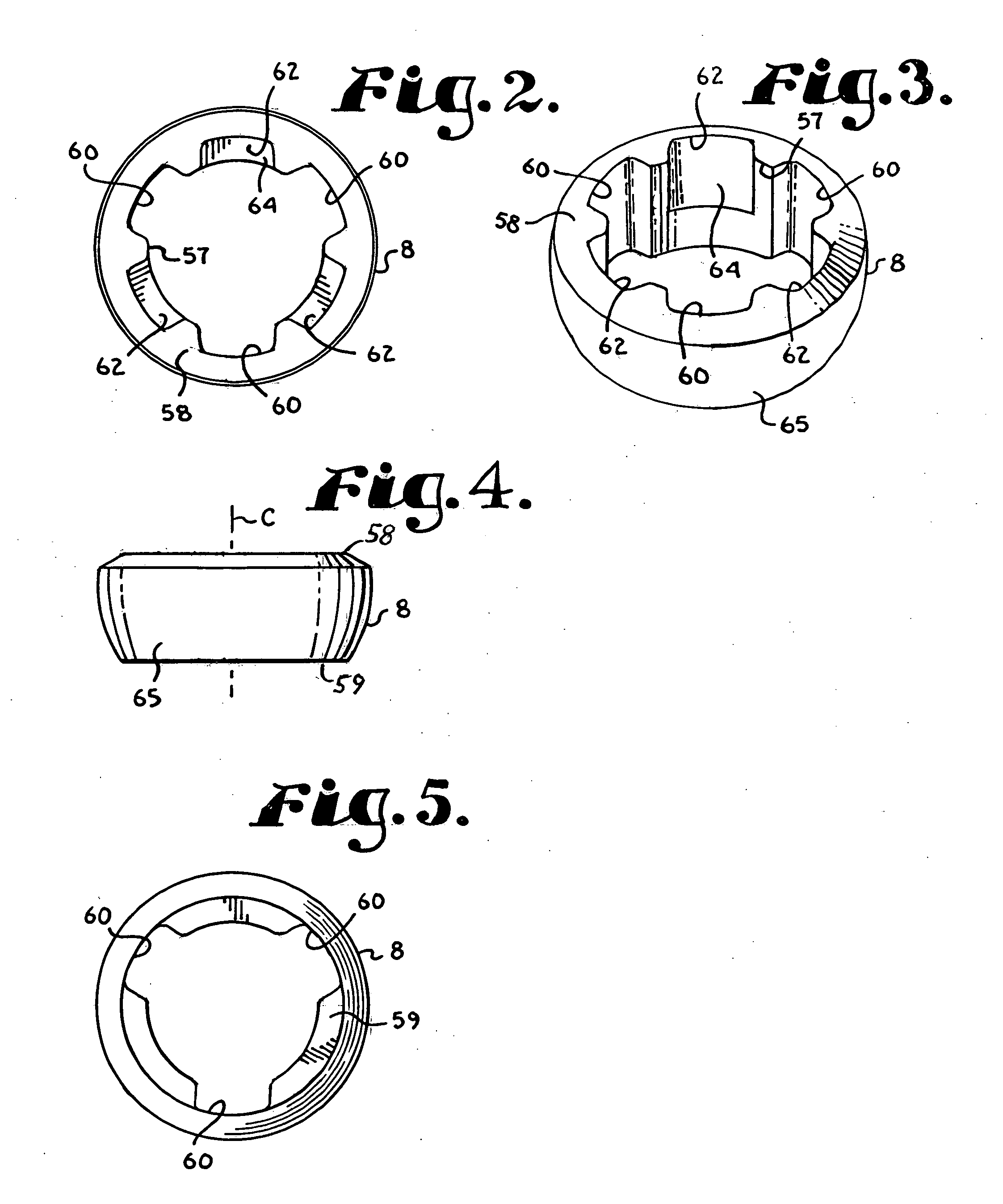

[0060]Illustrated in FIG. 19 is a retainer ring 88 in accordance with the present invention. The retainer ring 88 is quite similar to the retainer ring 8 of the previous embodiment except that it is noncontinuous and has a radially extending space or gap 90 from top to bottom along one side thereof. The gap 90 allows for expansion without requiring stretching of the material of construction of the ring 88, as is the case with the previous embodiment. The ring 88 includes a central bore 92, spline channels 93 and spline receivers 94 which are all similar to the similar structures described for the previous embodiment. The retainer ring 88 also has a partial hemispherical shaped surface 95 on the outer side thereof.

[0061]Illustrated in FIGS. 20 and 21 are elements of a third embodiment of the present invention including a shank 106 and a capture ring 107 which are used otherwise in the same manner as has been described in the first embodiment and, in particular, with a head such as he...

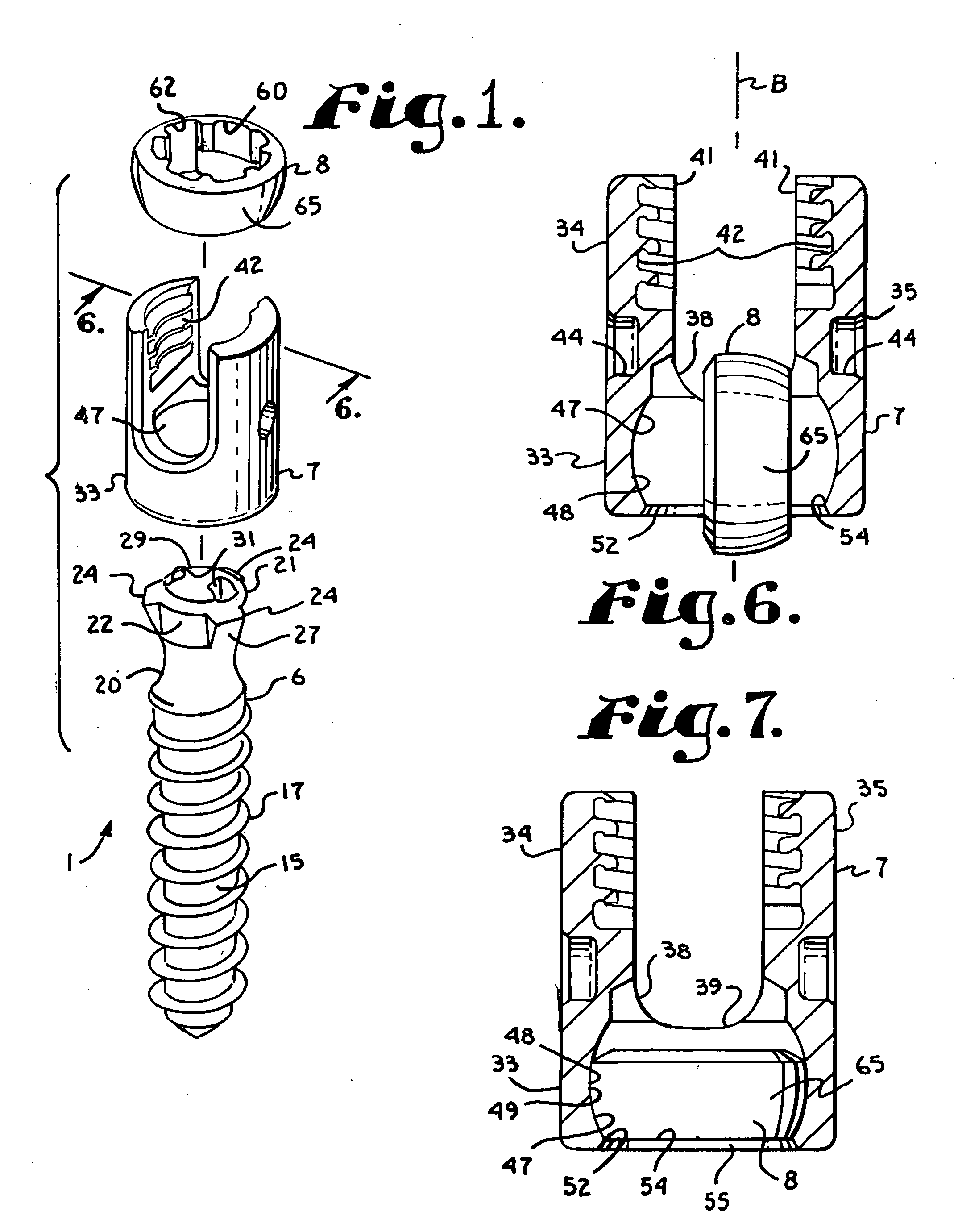

first embodiment

[0062]The capture ring 107, shown in FIG. 21, is otherwise similar to the retainer ring 8 except that it includes a set of four channels 126 and four recesses 127 that are sized shaped and positioned so as with respect to the channels 126 to allow the splines 120 to slidingly pass upwardly through and with respect to the recesses 127 to capture and receive the splines 120, as they move axially downwardly. The ring 107 has a partial hemispherical outer surface 129 that mates with the corresponding surface in the head 7 in the manner described for the

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com