Transfer layer for absorbent article

a technology of absorbent articles and transfer layers, applied in the field of formed films, can solve problems such as dampness and unpleasant feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

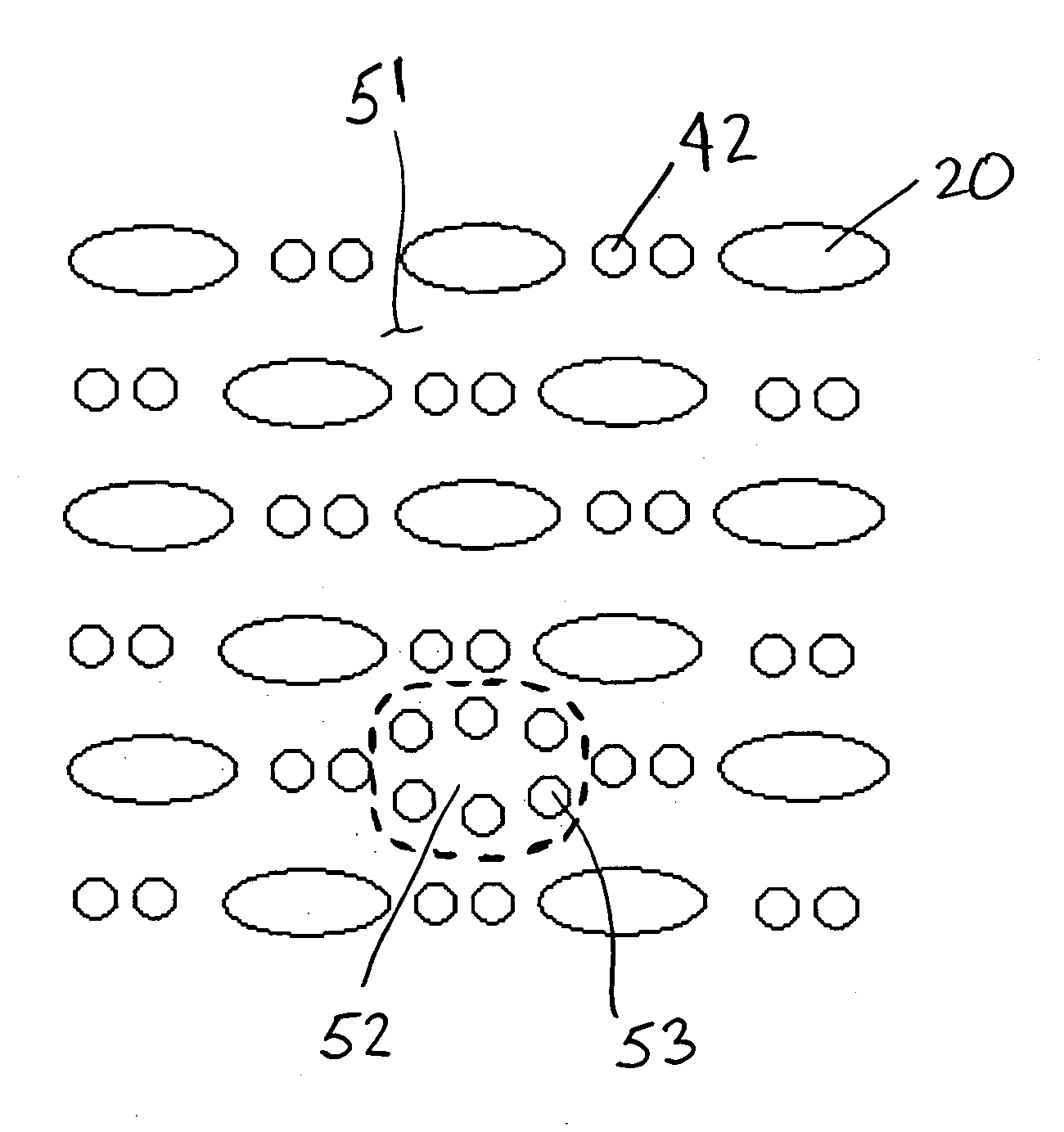

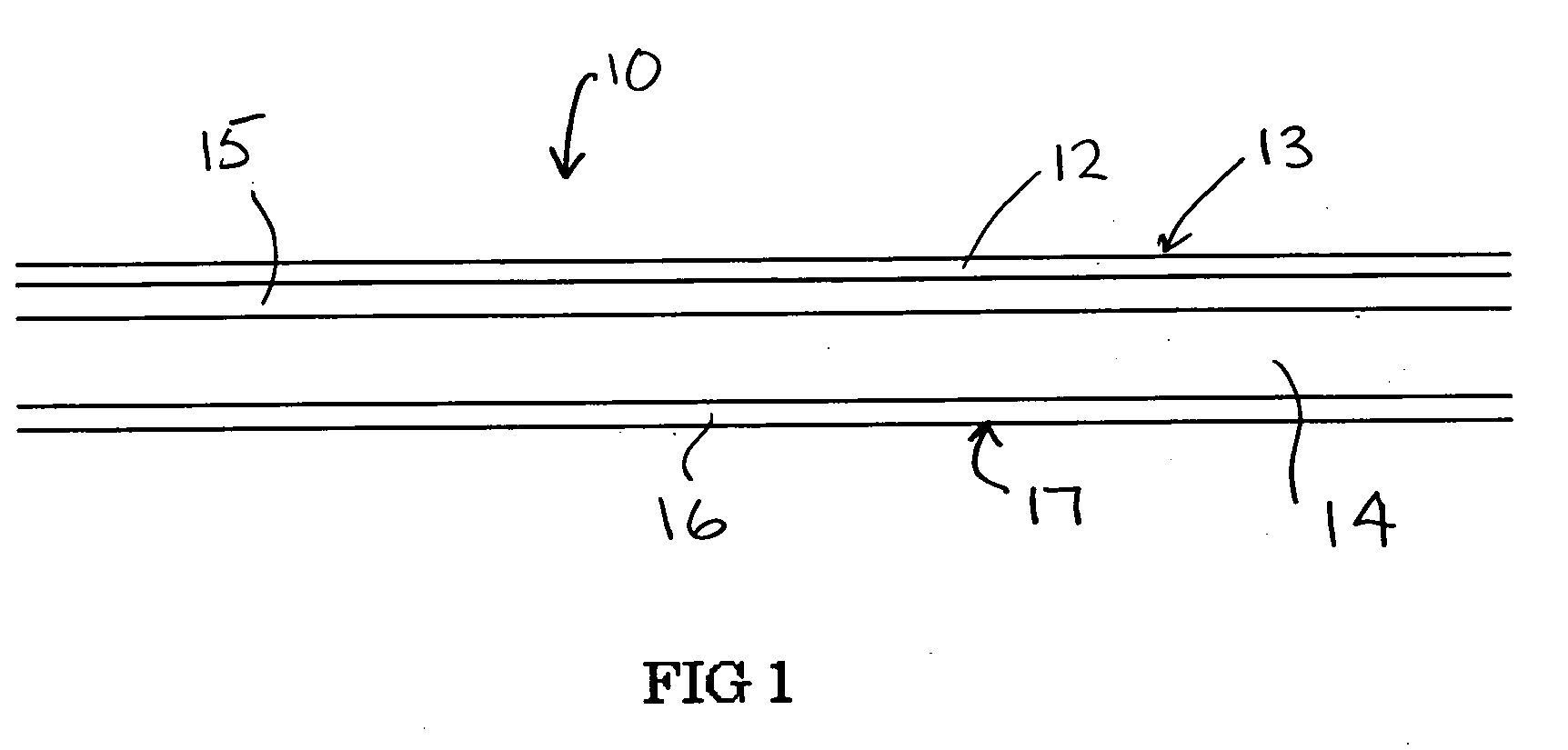

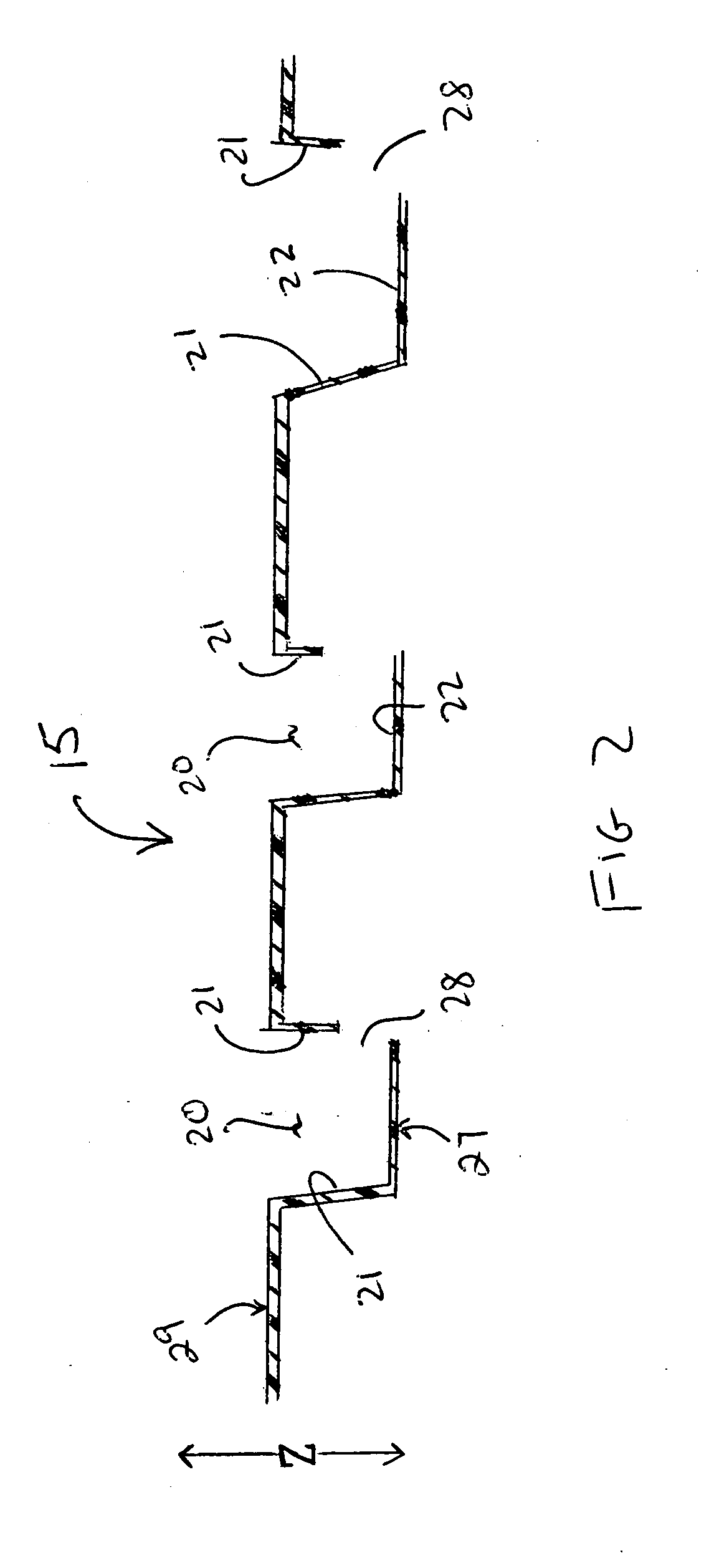

[0018]Absorbent articles generally comprise a topsheet, an absorbent core, and a backsheet. The topsheet is on the body facing side of the absorbent article and typically comprises a liquid pervious material that allows liquid from an insult to transfer from the body-facing surface of the absorbent article to the absorbent core. The term “insult” generally refers to an amount of a liquid or the act of adding a liquid on a topsheet of an absorbent article. An insult may occur during product use and during finished product testing. Consequently, “multiple insults” occur when the same absorbent article is insulted more than once. The topsheet is typically in close proximity or even direct contact with the wearer's skin during use and is typically made of a soft material such as a nonwoven material, an apertured film, or a combination of these materials made into a unitary composite. The topsheet is typically designed to retain a comfortable, dry feel to the wearer even after an insult....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com