Filterless and bagless vacuum cleaner incorporating a sling shot separator

a vacuum cleaner and separator technology, applied in the field of floor care equipment, can solve the problems of too much inertia of the large particles in the rotating stream to follow the tight curve of the stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

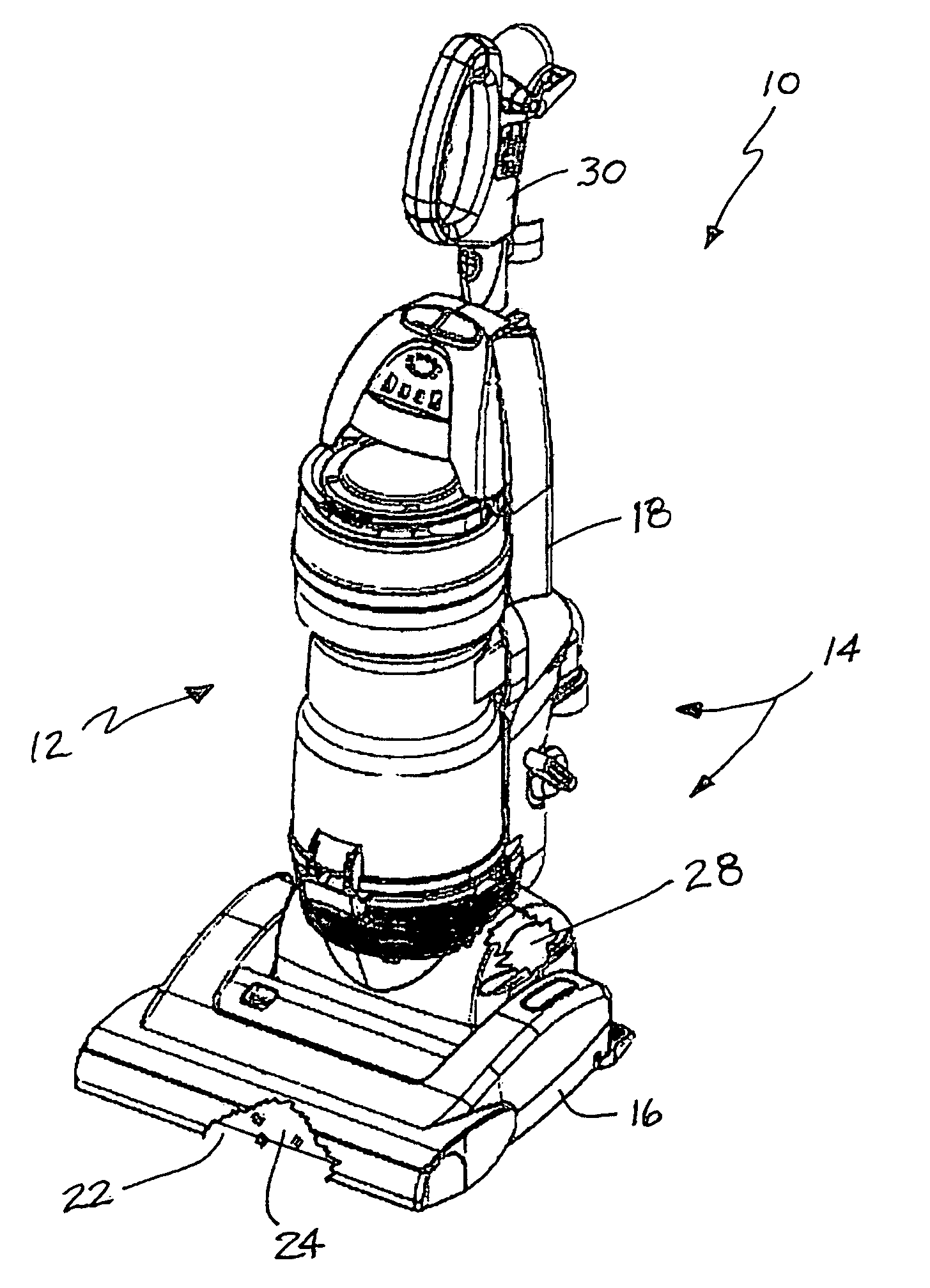

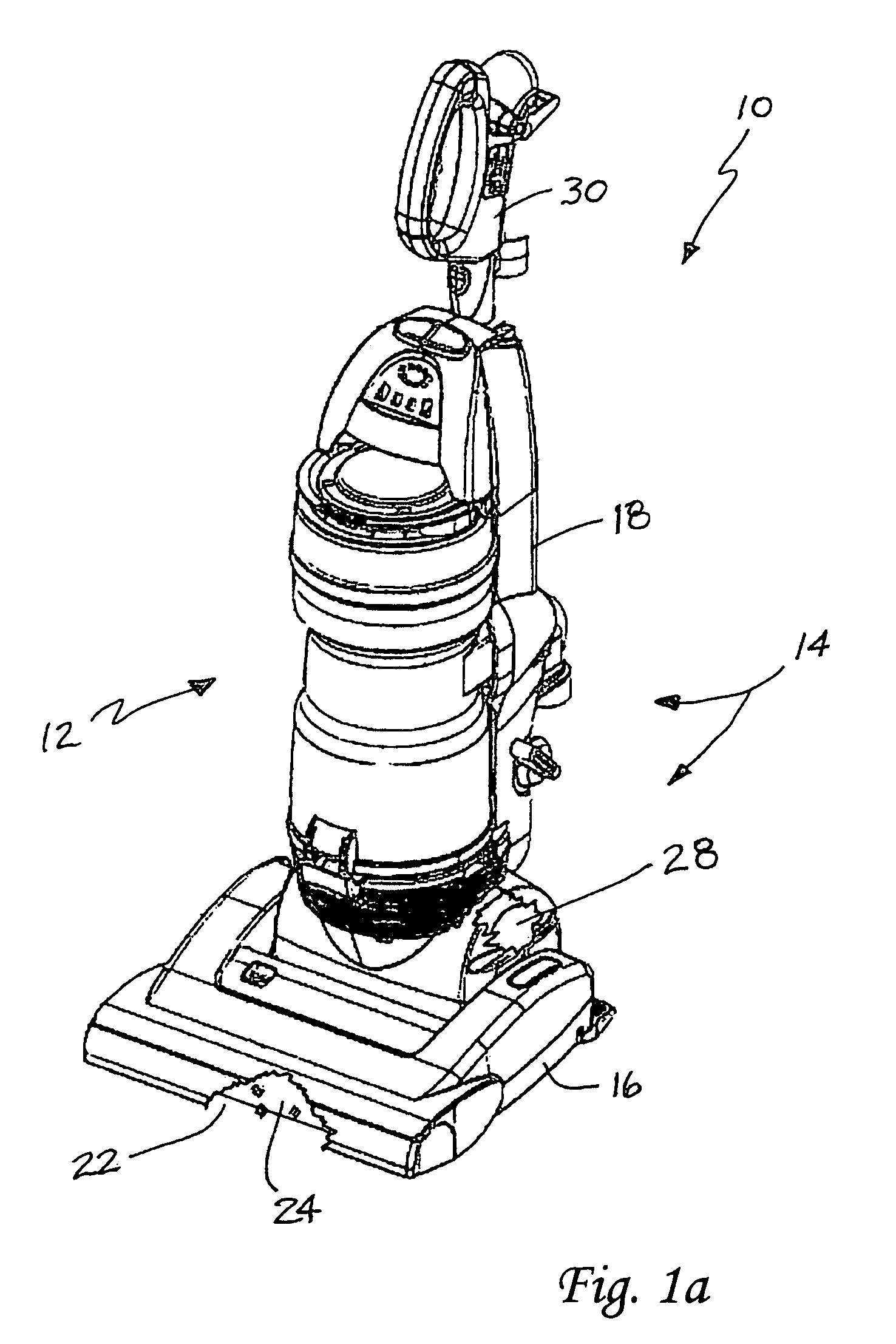

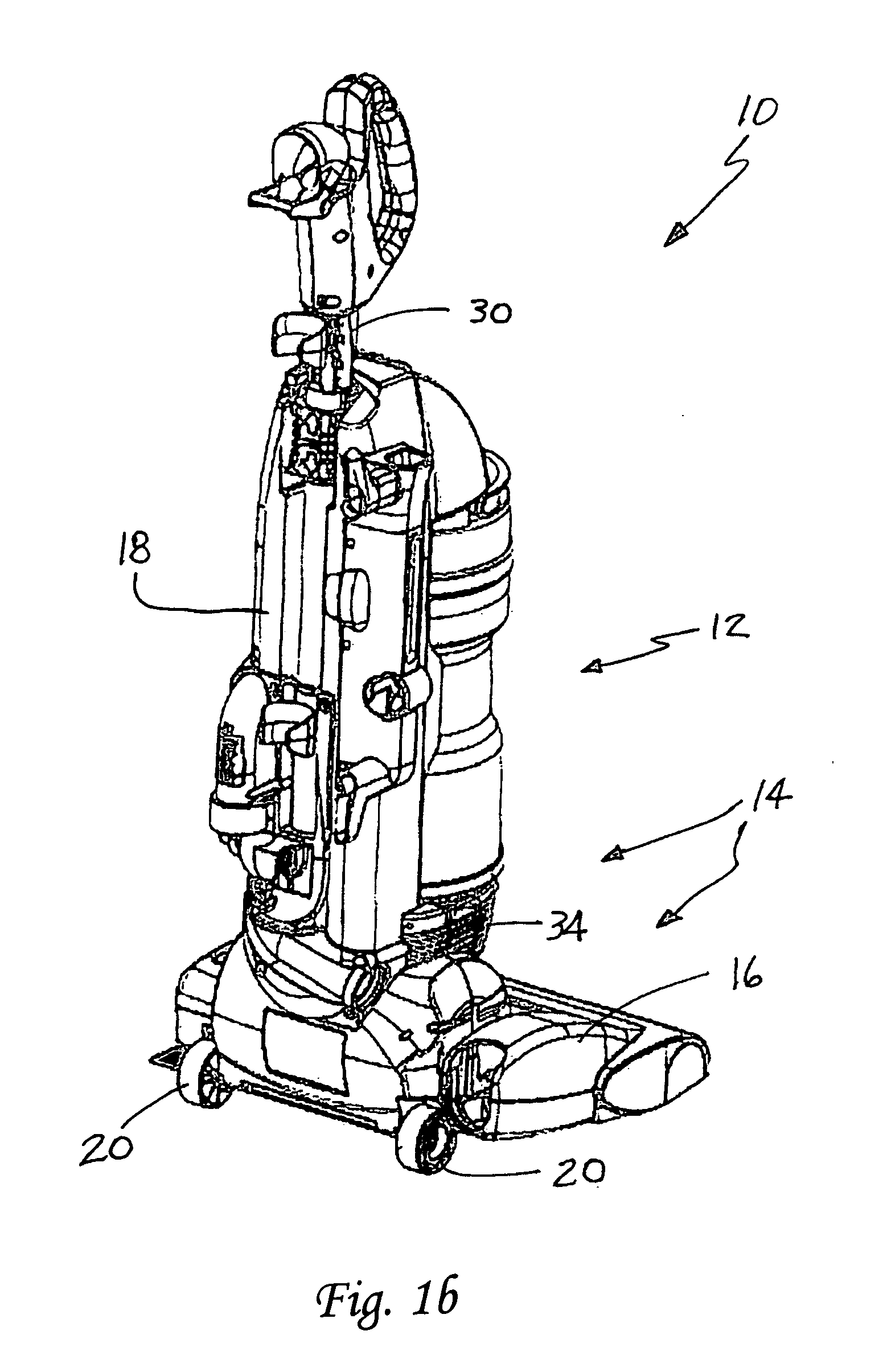

[0019]Reference is now made to FIG. 1 illustrating an upright vacuum cleaner 10 of the present invention. While an upright vacuum cleaner 10 is illustrated, it should be appreciated that the present invention is not limited to upright vacuum cleaners but instead covers any type of vacuum cleaner incorporating the novel dirt collection vessel 12 of the present invention. This includes but is not limited to, canister vacuum cleaners.

[0020]The vacuum cleaner 10 includes a body, generally designated by reference numeral 14. The body 14 includes a nozzle assembly 16 and a control or handle assembly 18. As is known in the art, the control assembly 18 is pivotally connected to the nozzle assembly 16 to aid the operator in manipulating the vacuum cleaner 10 back and forth across the floor. Wheels 20 (only two illustrated) carried on the body 14 allow the vacuum cleaner 10 to be moved smoothly across the floor. As illustrated, the nozzle assembly 16 is equipped with a suction inlet 22. A rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com