Trash receptacle vacuum release vent

a technology for trash receptacles and vents, which is applied in the field of trash receptacles, can solve the problems of requiring a person, unable to adapt to retrofitting an ordinary trash receptacle with a vacuum release mechanism, and the simple task of removing a trash bag from its receptacle is rendered difficult and awkward,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

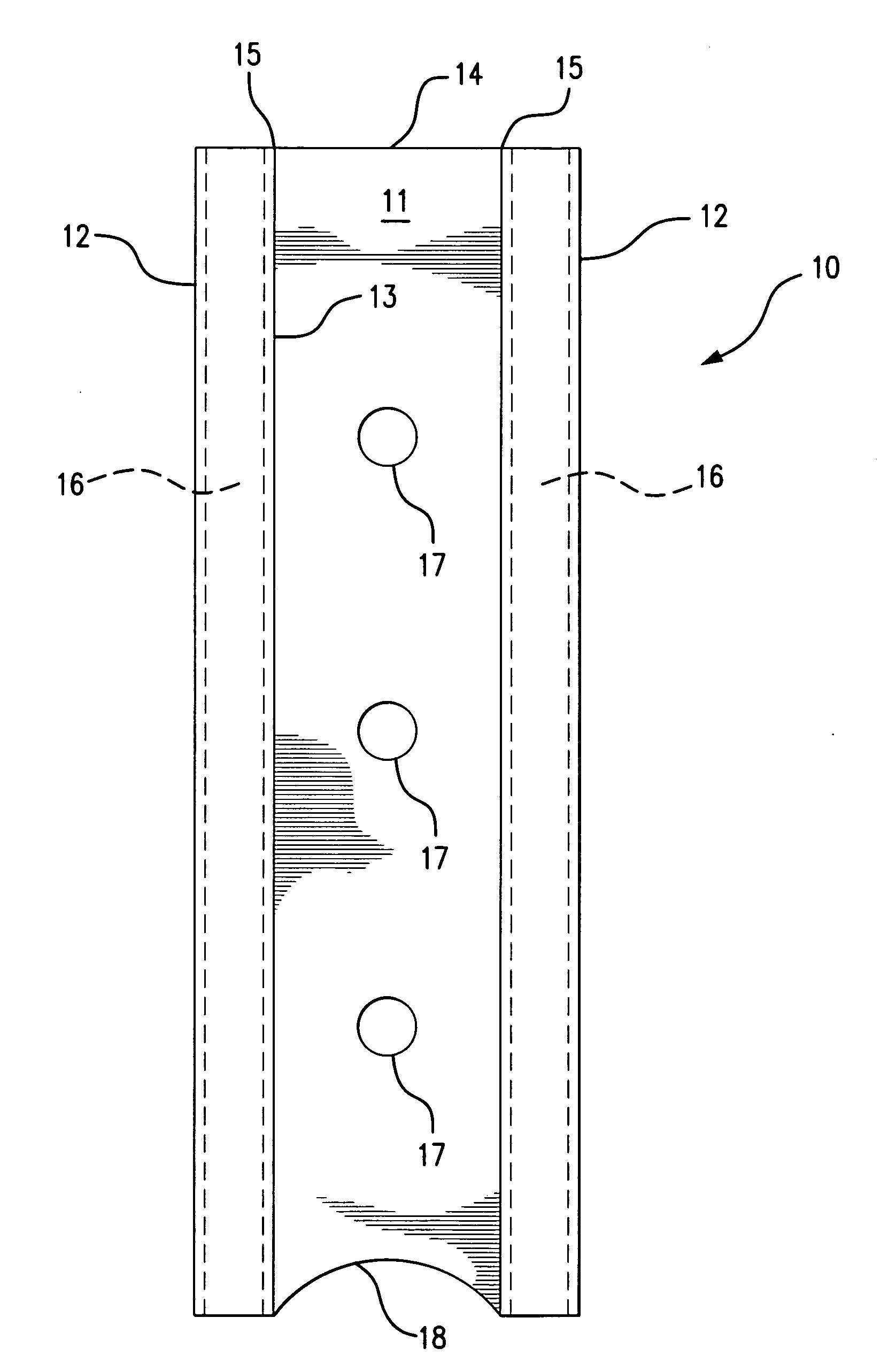

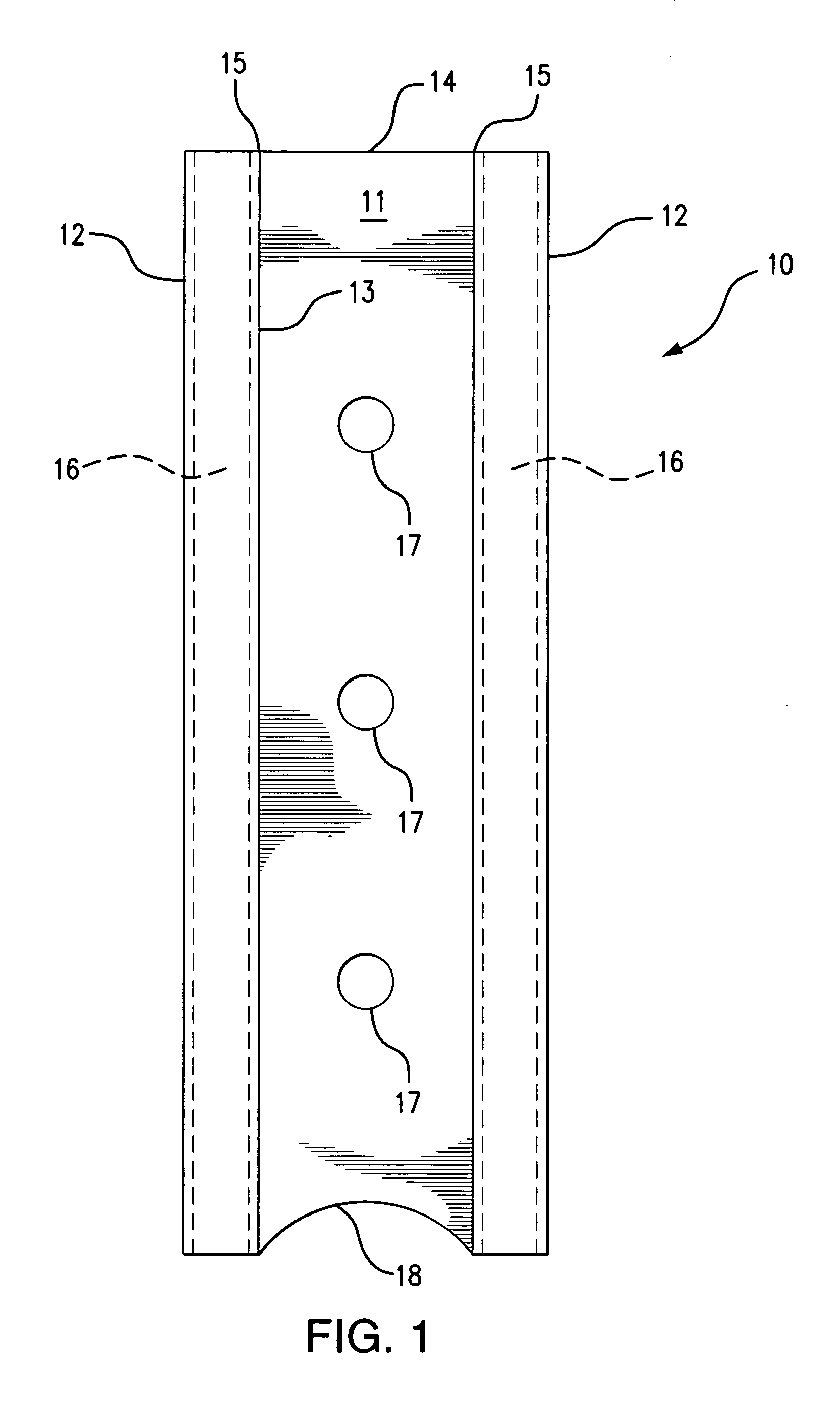

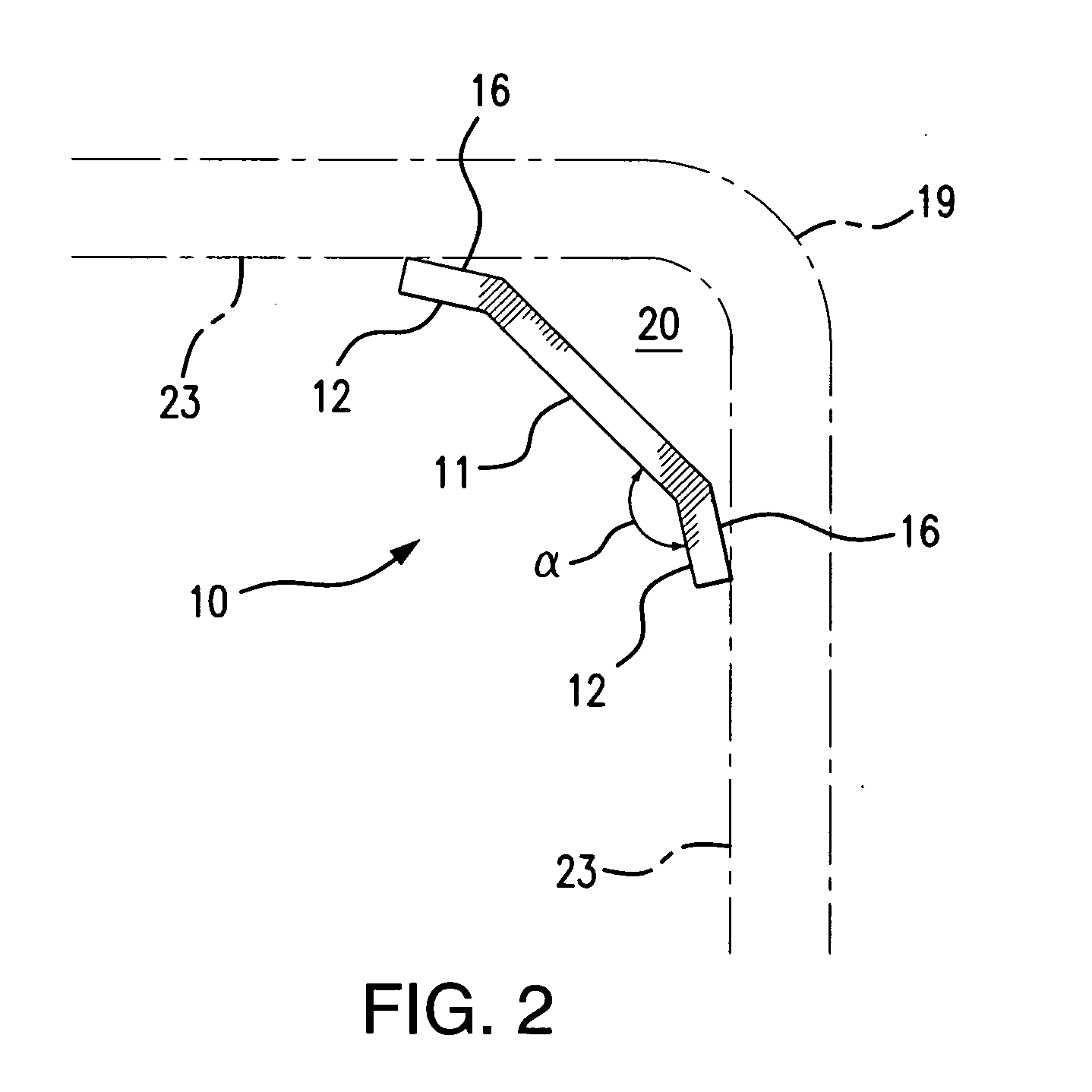

[0017]Referring to FIG. 1, the first embodiment of the present invention comprises a composite vent 10 having a central panel 11 to which are hingeably attached two side panels 12. The central panel 11 is rectangular in shape, with two elongated longitudinal sides 13 and two narrower lateral sides 14. Preferably, the length of the longitudinal sides 13 is in the range of 12 to 48 inches, corresponding to the height of the trash receptacle into which it will be inserted, while the width of the lateral sides 14 is in the range of 2 to 8 inches, depending on the size of the receptacle opening. The cross-section of the central panel 11 is preferably flat, but can be also be convex or concave, so as to better conform to the shape of the receptacle.

[0018]The two side panels 12 are hingeably attached along the two longitudinal sides 13 of the central panel 11. The length of the side panels 12 is equal to the length of the longitudinal sides 13 of the central panel 11, while the width of ea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap