Drilling device and process

a drilling device and drilling technology, applied in the field of drilling holes, can solve the problems of high cost, wear and tear of drill bits, and the loss of drilling days to replace bits once or twice a week,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

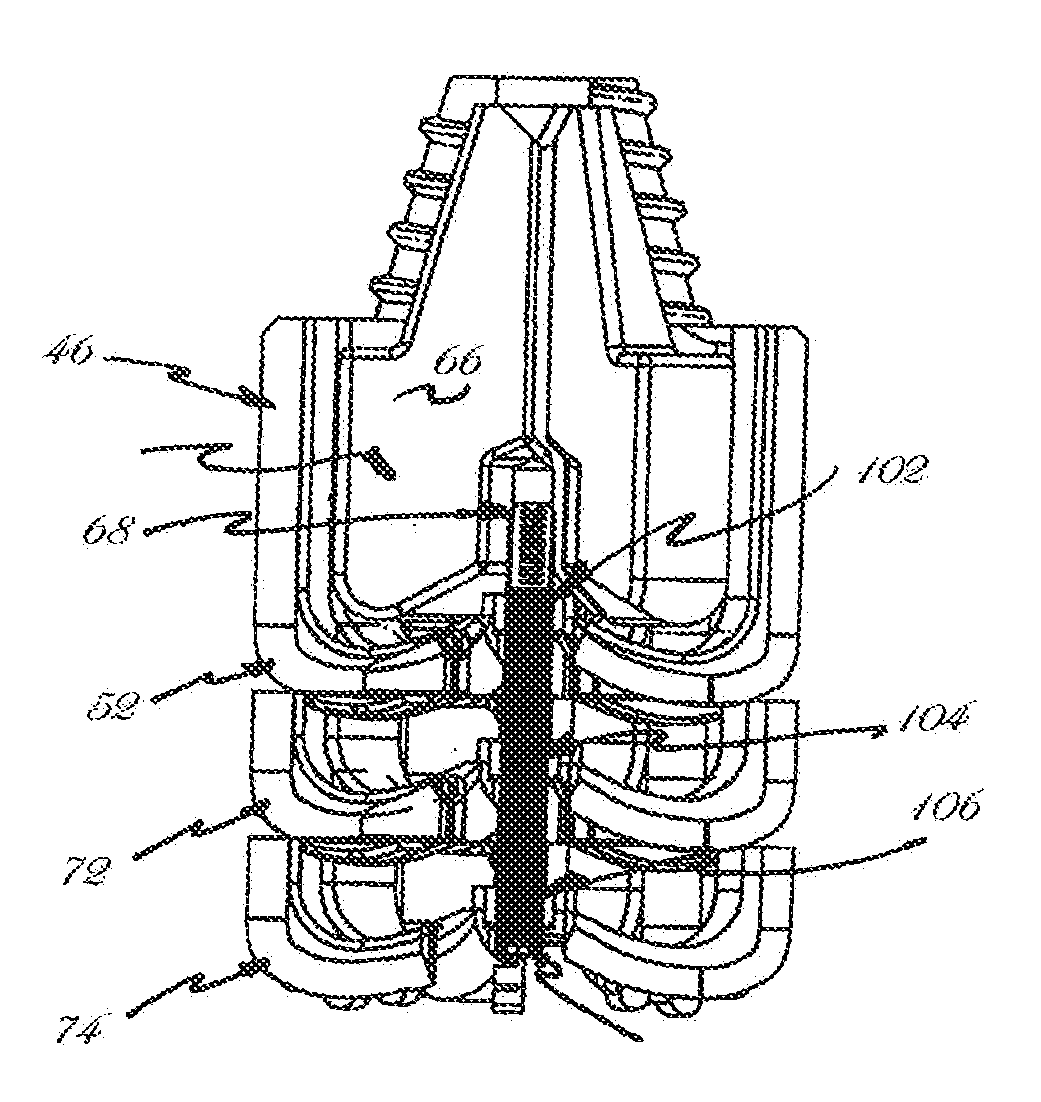

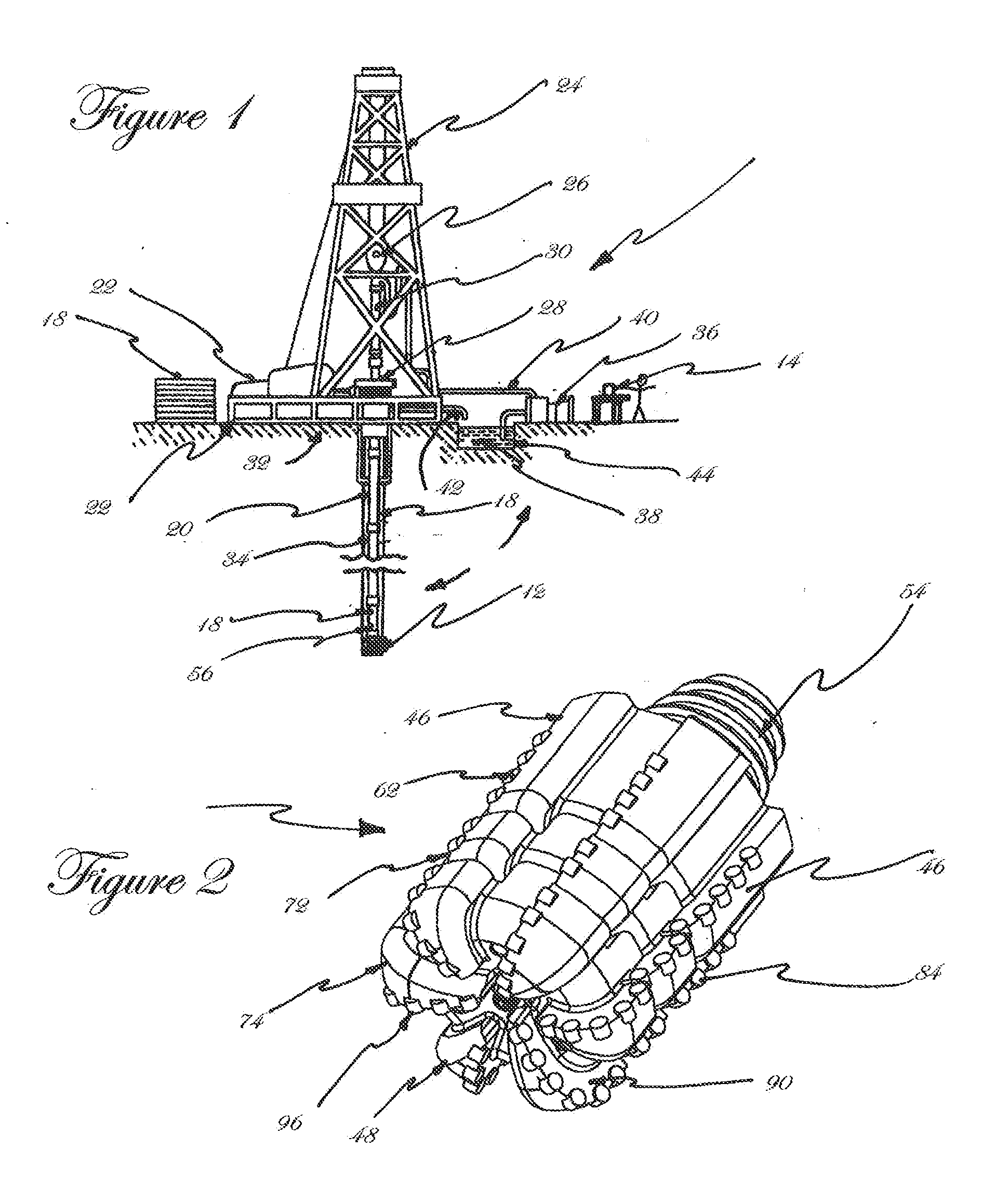

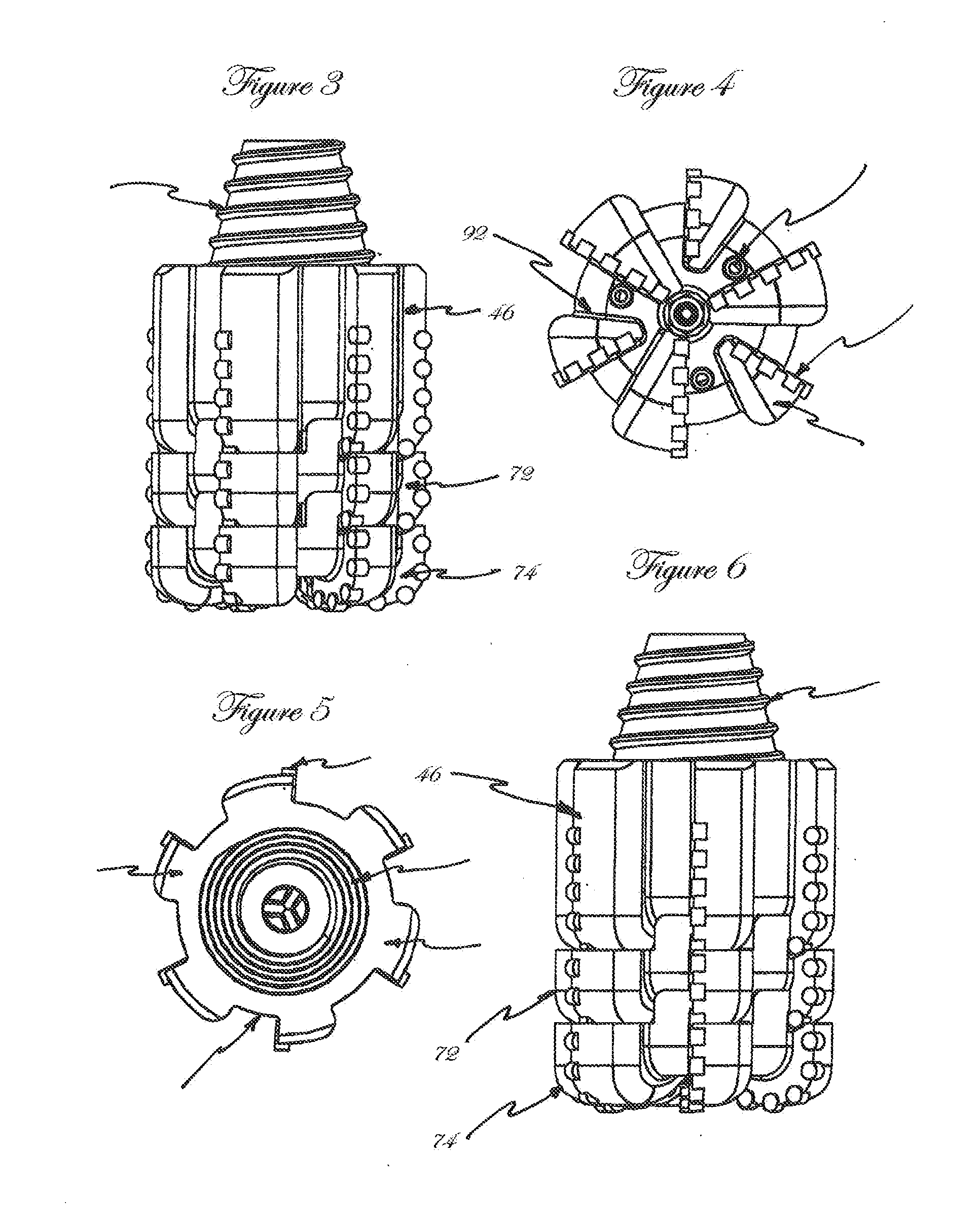

[0028]Now referring to the Figures, a preferred embodiment of a drilling device of the present invention is indicated generally by the numeral 10. Drilling device 10 comprises drill bit 12 and remote control 14 and is shown in FIG. 1 in use in an otherwise typical oil drilling rig 16. Drill bit 12 is attached to the lowest of the many pipe sections 18 which have been connected end to end to comprise drill string 20. Additional pipe sections 18 are shown in FIG. 1 as stored on site for use during the drilling process. As illustrated in FIG. 1, drilling rig 16 also includes platform 22 which supports derrick 24 and has traveling block 26 for raising and lowering drill string 20, rotary table 28 for rotating drill string 20 and kelly 30 which allows drill string 20 to rotate while it is lowered or raised. It will be appreciated by those skilled in the art that drilling device 10 is useful with a wide variety of drilling rigs and that oil drilling rig 16 is shown as illustrative of one ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap