Tackless carpet strip

a technology of carpet strips and nails, applied in the direction of carpet fasteners, sheet joining, fastening means, etc., can solve the problems of not being able to install strips, need nails (tacks) to secure strips into the floor, and sometimes impossible to install concrete nails into old concr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

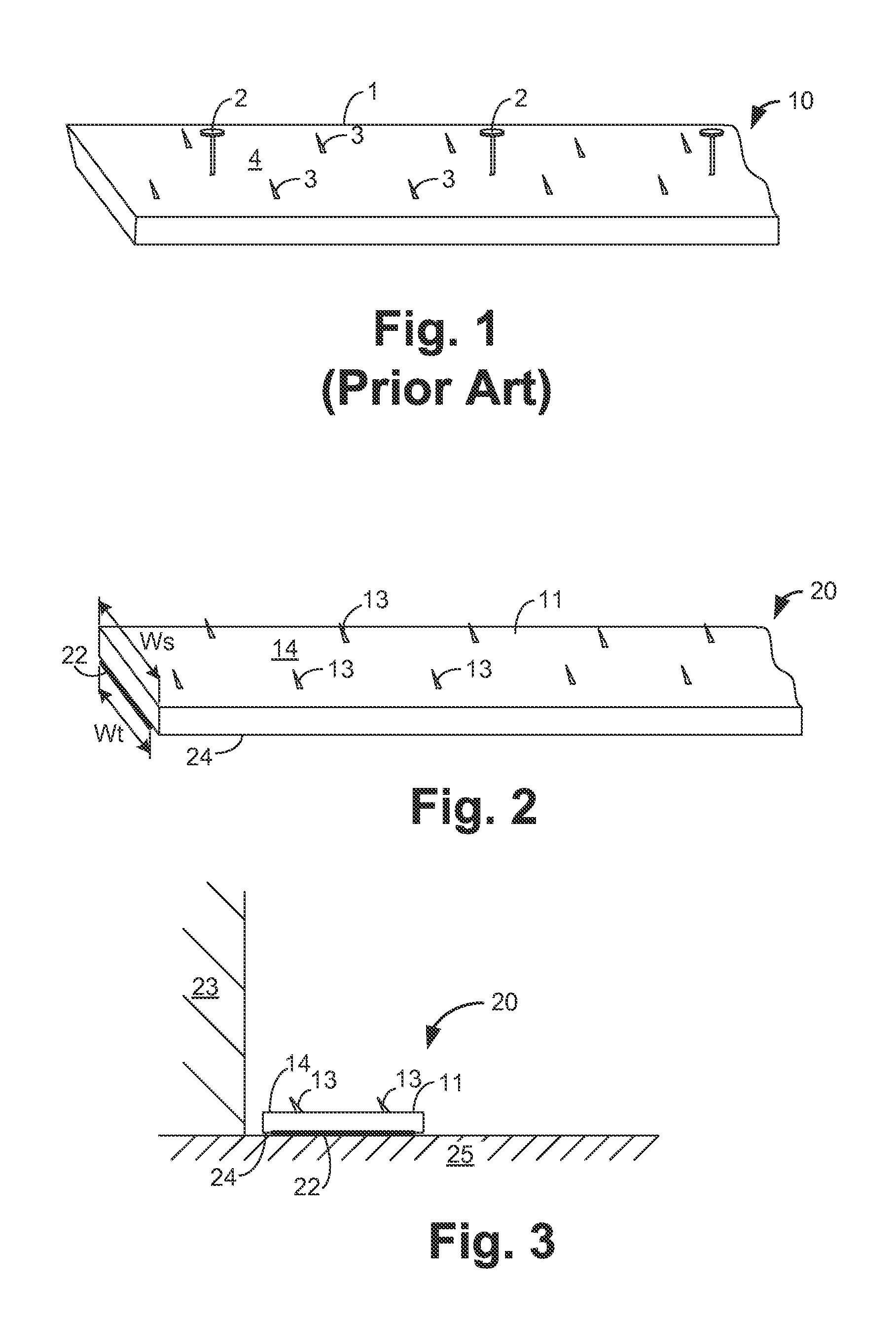

[0022]FIG. 1 is a perspective view of a prior art carpet tack strip 10. The strip 10 comprises a strip base 1 that is formed from wood or other suitable material. The strip 10 has a top surface 4 from which a plurality of spikes 3 protrude upwardly at an angle. A plurality of tacks or nails 2 extend through the strip base 1 and are driveable into a floor (not shown) to secure the strip 10 to the floor. The spikes 3 angle toward a wall (not shown) against, which the strip 10 is installed, and the spikes 3 anchor a carpet (not shown) that is installed on the floor and stretched from strip to strip.

[0023]FIG. 2 is a perspective view off the tackless carpet strip 20 according to an embodiment of the present disclosure. The strip 20 comprises a strip base 11, which is formed from wood or other suitable material, such as plastic or aluminum. The strip 20 has a top surface 14 from Which a plurality of spikes 13 protrude upwardly at an angle. No nails 2 (FIG. 1) are required to secure the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com