Safety magazine for firearms

a safety magazine and firearm technology, applied in the field of firearms, can solve the problems of increasing the probability of accidental, negligent or unauthorized discharge of various firearms, especially handguns, ammunition is unintentionally left in the chamber, and the probability of unintentional loading of firearms is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

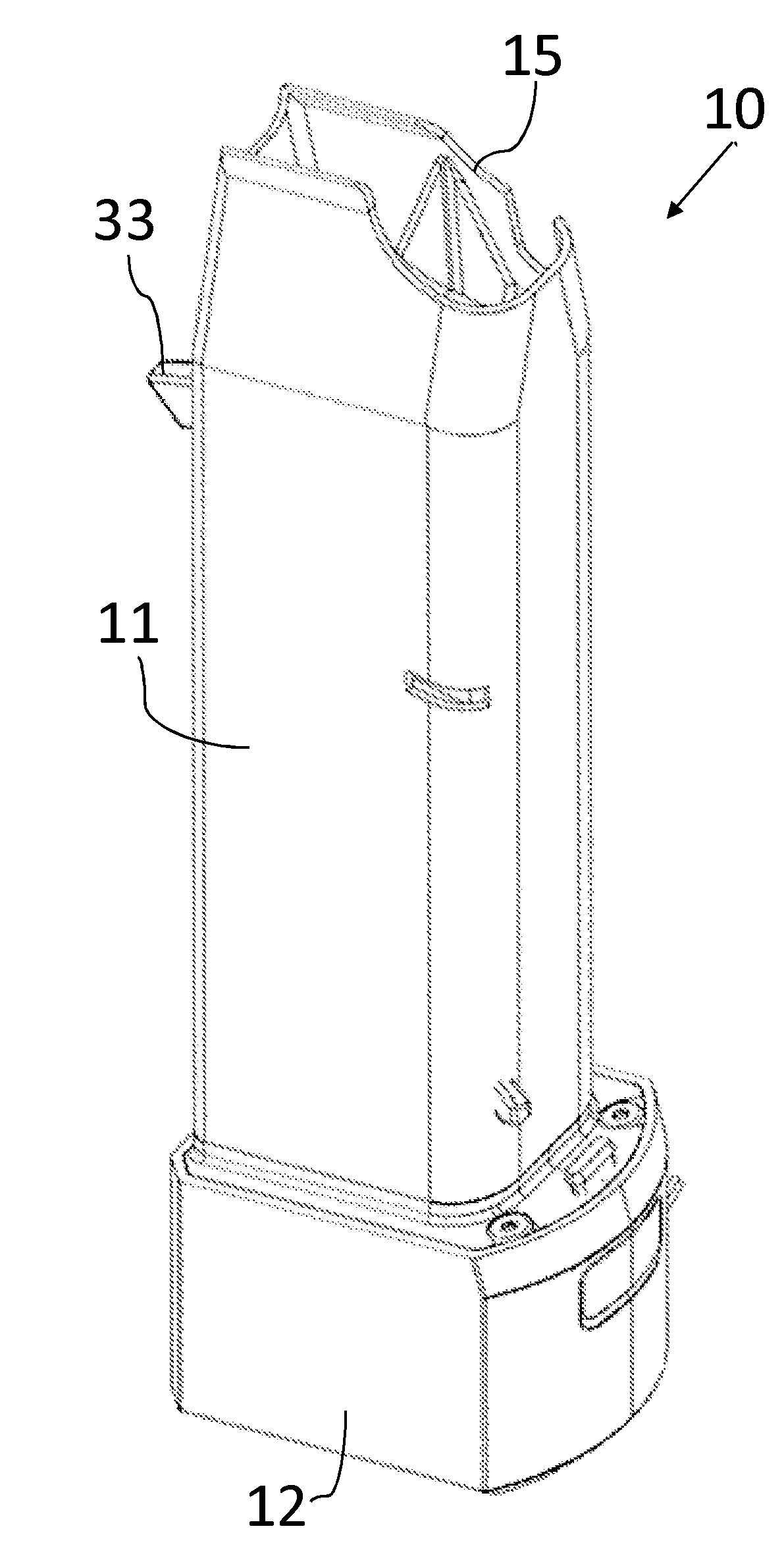

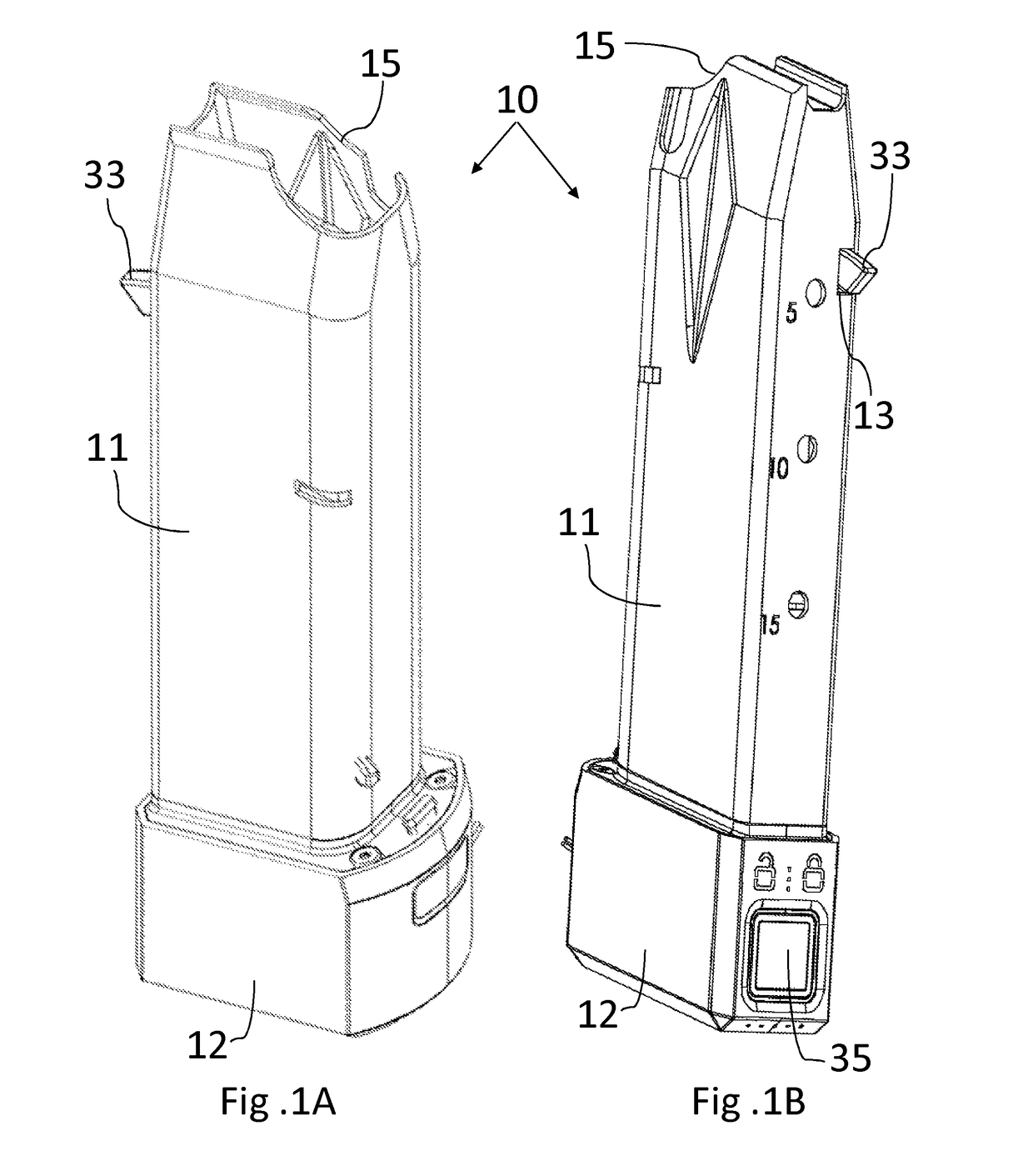

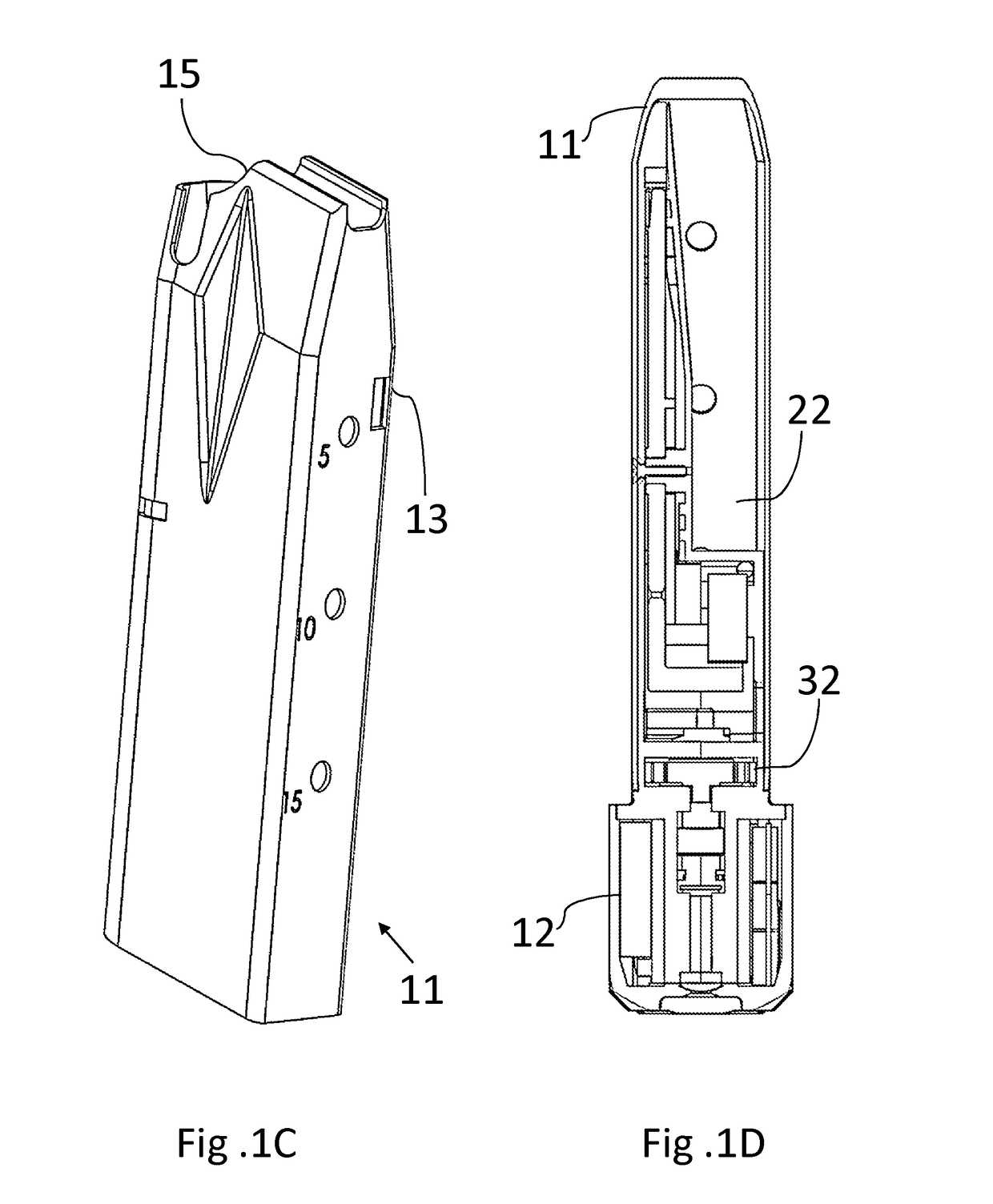

[0038]Reference is now made to FIGS. 1A-1B, which illustrate a safety magazine, generally designated 10, according to a preferred embodiment of the present invention. FIG. 1A illustrates a frontal perspective view of a safety magazine 10, and FIG. 1B illustrates a back perspective view of the safety magazine 10.

[0039]The safety magazine 10 comprises a top cover 11 having a structure compatible with commercially available magazines for firearms, for instance having a shape corresponding to and adapted to be inserted into a magazine housing of, for example, a Beretta 6-bullet handgun. The safety magazine 10 further comprises a bottom cover 12 that at least partially covers the safety mechanism, further described hereinafter. Optionally, the top cover 11 has a top portion 15 that is configured to couple with the magazine housing in a compatible firearm. It is appreciated that a top locking element (or latch) 33 is designed to be capable of protruding from an opening 13 in the top cover...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap