Needle assembly

a technology of needles and assemblies, applied in the field of needle assemblies, can solve the problems of hubs not providing means to prevent users, spinal and epidural needles are somewhat difficult to manipulate by surgeons or anesthesiologists, etc., and achieve the effect of preventing the coring of the needl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

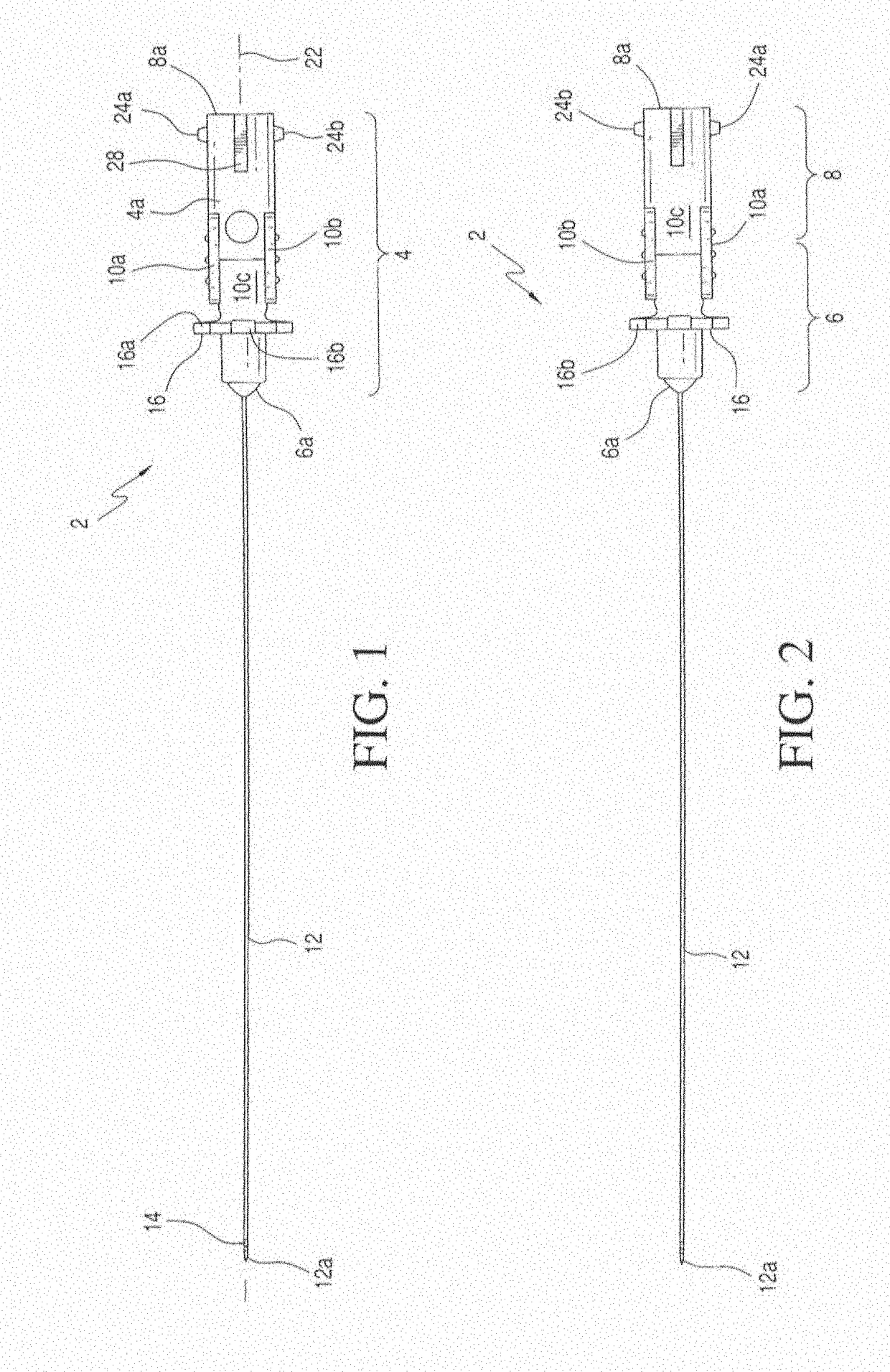

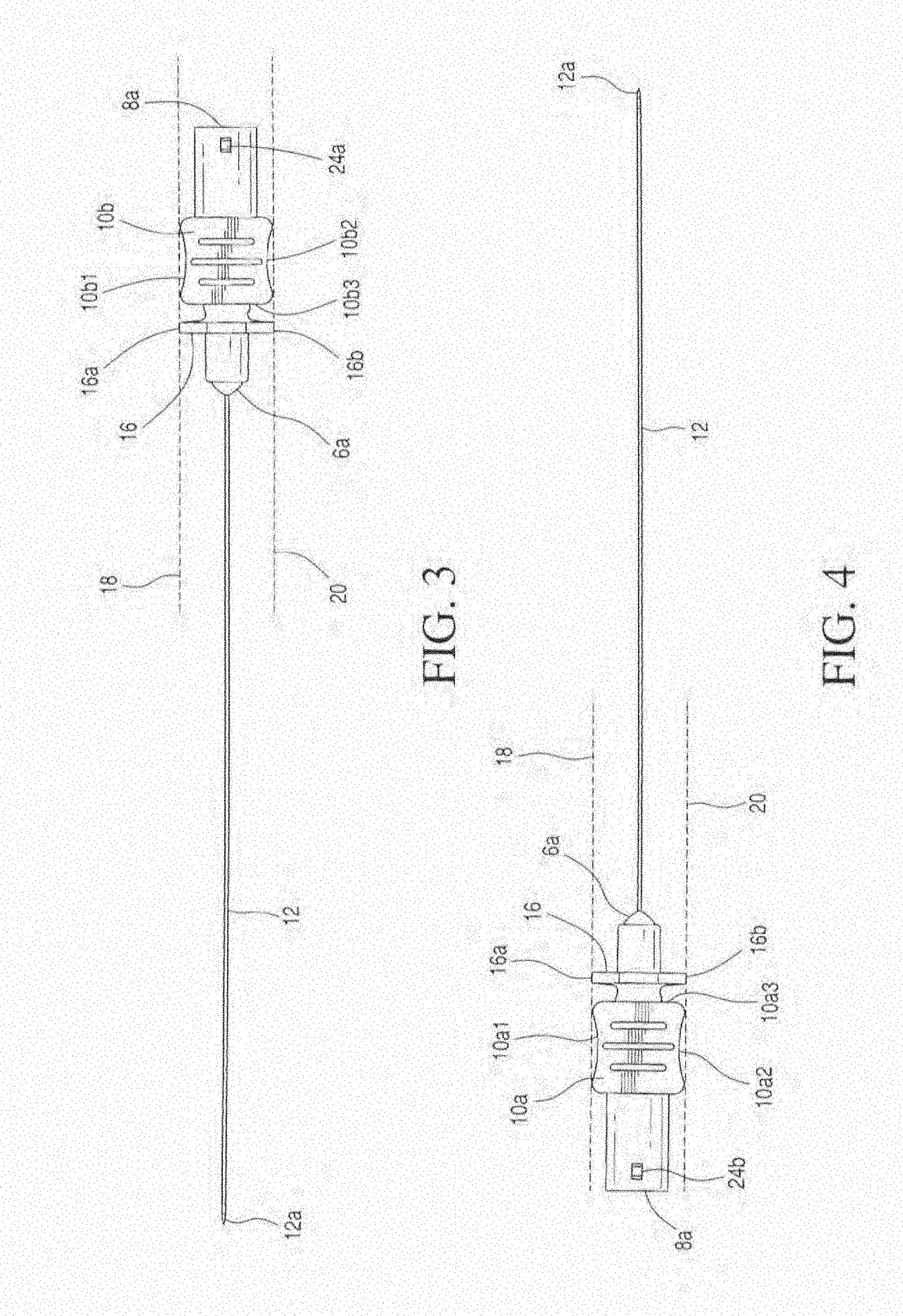

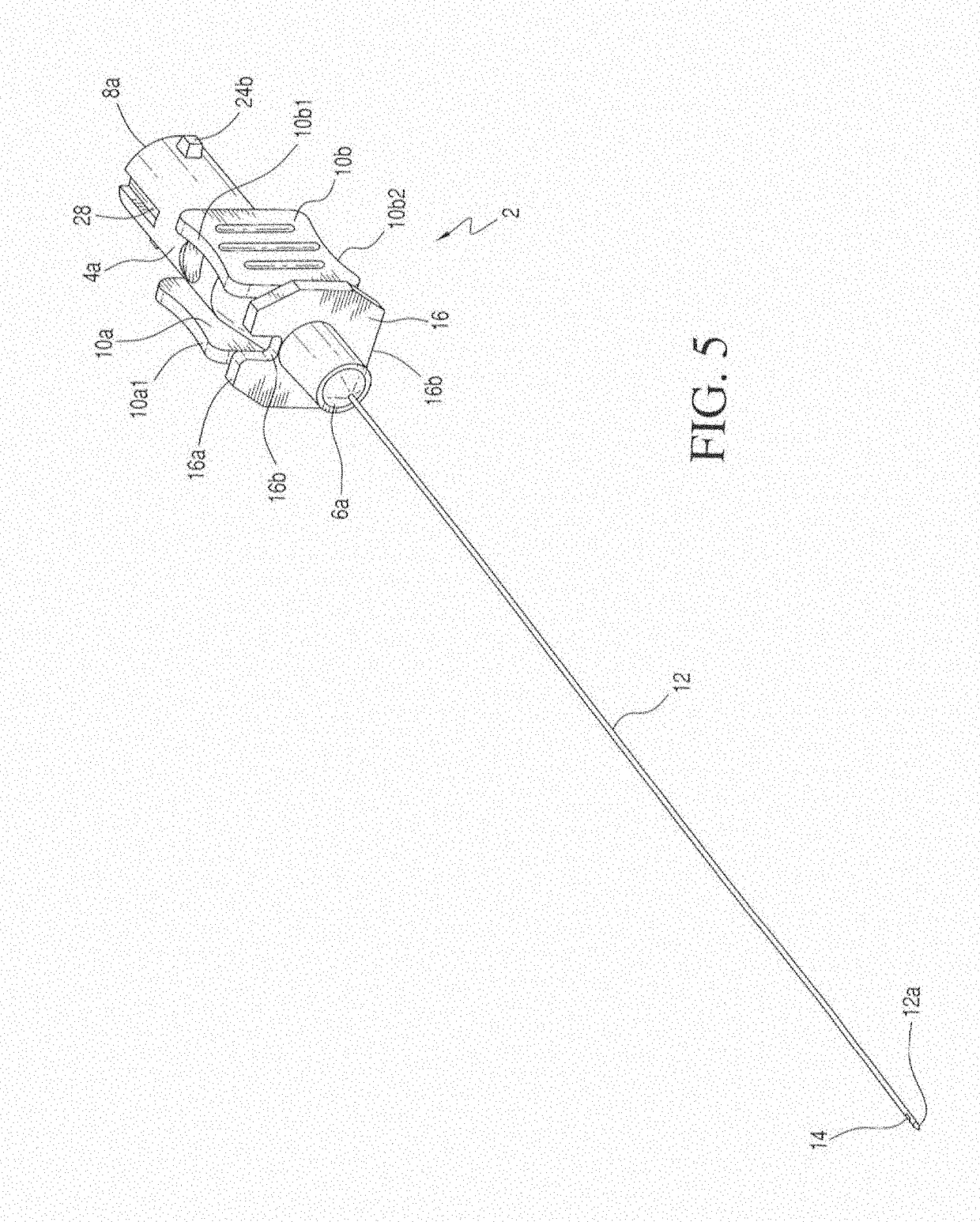

[0022]With reference to the figures, needle assembly 2 of the instant invention is shown to have a needle hub 4 that includes a distal portion 6 and a proximal portion 8. It should be appreciated that although designated as such in FIG. 2, there is no actual line of demarcation between distal portion 6 and proximal portion 8. Distal portion 6 has a closed distal end 6a, whereas proximal portion 8 has an opened proximal end 8a. Needle hub 4 has a main body 4a that is substantially cylindrical along proximal portion 8 and slopes or inclines downwards in a conical fashion towards distal end 6a along distal portion 6.

[0023]Two flats or plates 10a and 10b are bonded to body 4a bridging distal portion 6 and proximal portion 8. Plates 10a and 10b each are substantially rectangular in shape, with their respective upper edges 10a1, 10b1 and their respective lower edges 10a2 and 10b2, slightly curved inwardly to form a slight concave configuration. For the instant invention, the respective up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com