Continuously variable transmission using oscillating torque and one-way drives

a technology of oscillating torque and one-way drive, applied in the direction of clutches, non-mechanical actuated clutches, gearing, etc., can solve the problem of reducing the overall efficiency of the transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

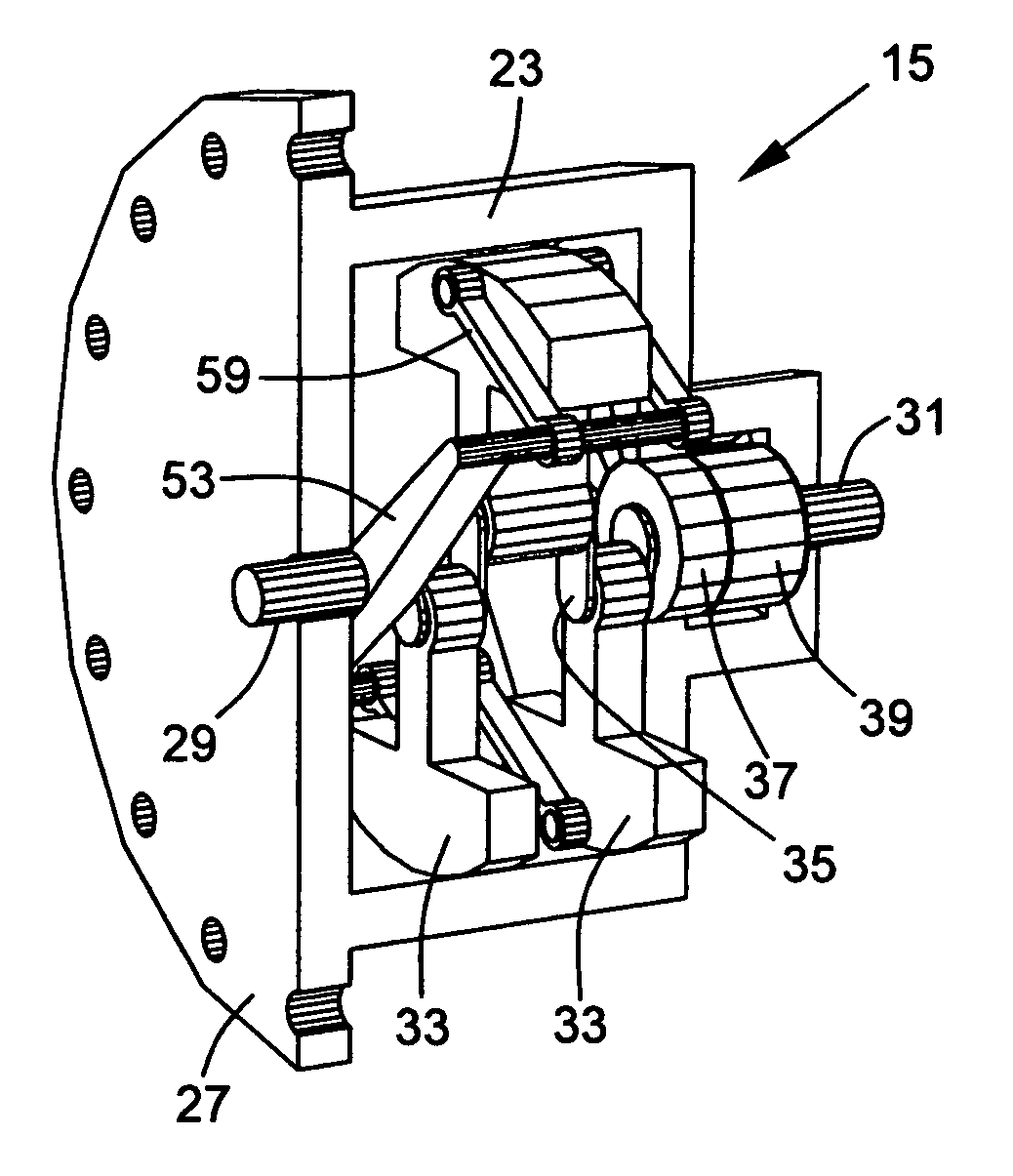

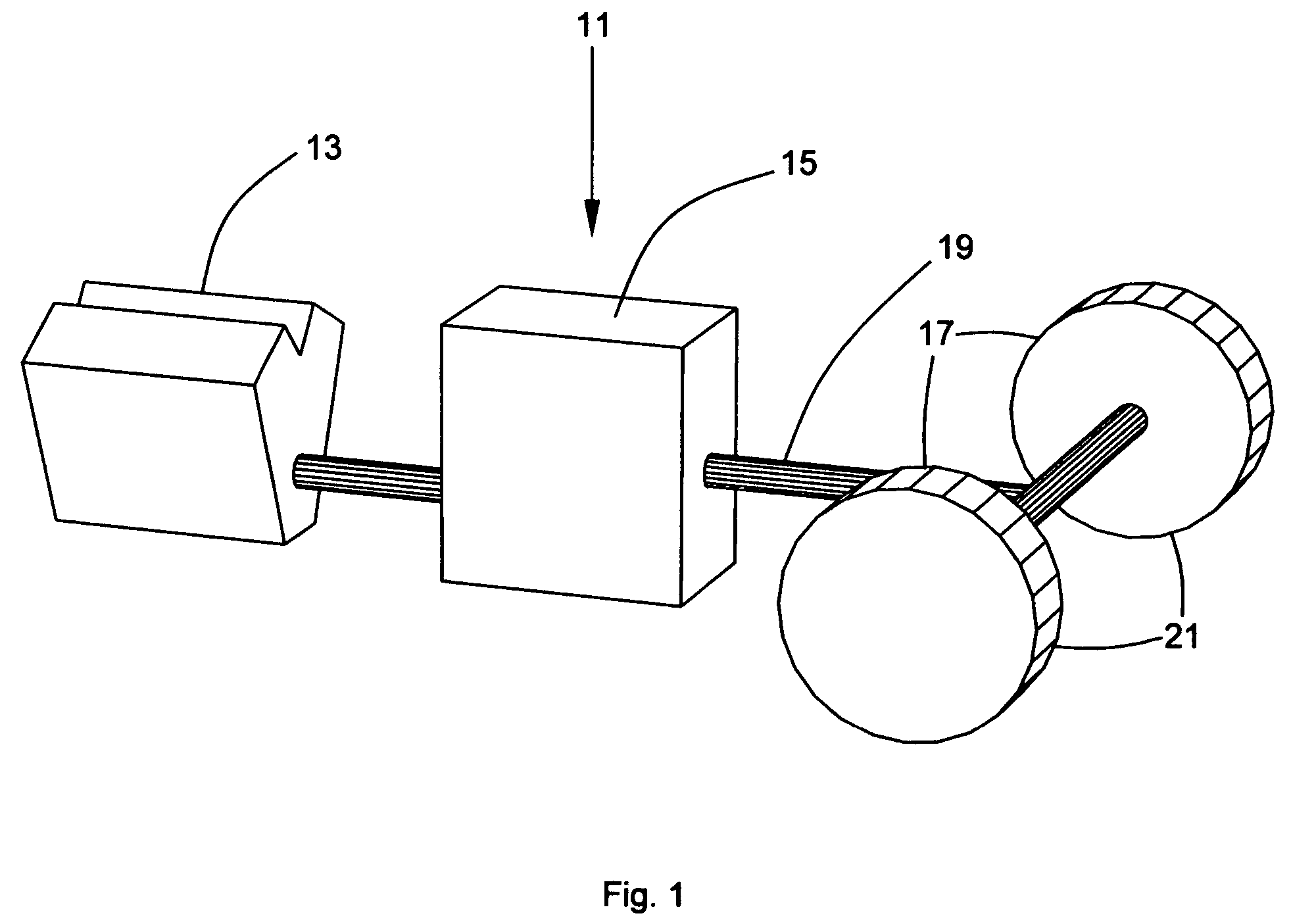

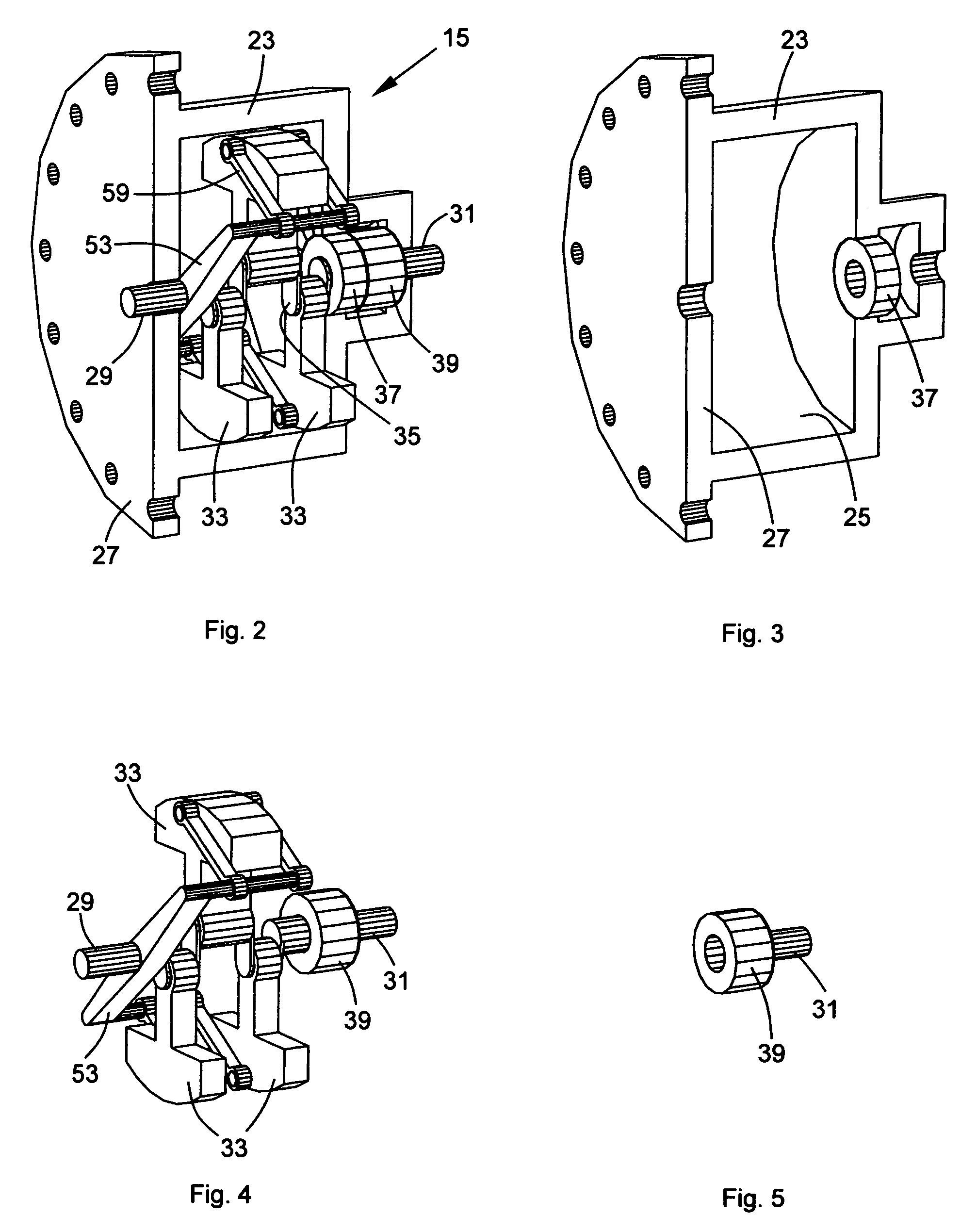

[0025]In FIG. 1, there is shown a schematic diagram of a vehicle power system 11. The system has a prime mover 13, a transmission 15, and an output load 17.

[0026]The prime mover 13 is typically an internal combustion engine that can be powered by gasoline, diesel, natural gas, etc. Alternatively, the prime mover can be electric motors or some other source of power.

[0027]The transmission 15 is that of the present invention, shown in accordance with a preferred embodiment. The transmission 15 has an input that is connected to the prime mover 13 and an output that is connected to the load 17. The load 17 is shown as being a drive shaft 19 and vehicle wheels 21.

[0028]The transmission 15 is of a continuously variable type. Many internal combustion engines (and electric motors) operate more efficiently within a narrow range of engine speeds. A continuously variable transmission can be provided with a narrow range of input speeds and produce a wide range of output speeds for the load. Unli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com