Image reproducing and forming apparatus, printer driver and data processing apparatus

a technology of image reproducing and forming apparatus, printer driver, and data processing apparatus, which is applied in the direction of typewriters, thin material handling, printing, etc., can solve the problems of cost-relation, difficulty for offices and companies to introduce inkjet recording apparatuses, and high cost of special purpose paper. achieve the effect of correcting color differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0137]FIG. 19 shows an example of gamma correction performed by the printer driver 91 according to the To perform ink adhesion control for reducing color difference in bidirectional recording, input data are supplied to a factor K multiplier 303. The input data values are multiplied by factor K, and then supplied to a gamma correction table 301. On the other hand, if the input data do not require ink adhesion control, the input data are supplied directly to the gamma correction table 301. A selector 303 determined whether the input, data are to be supplied directly to the gamma correction table 301 or to the factor K multiplier 302.

[0138]Gamma correction is a process for converting the gradation level of the input data to a different gradation level taking the image forming characteristics of the recording apparatus into consideration. The input data are data that are to be subjected to gamma correction, and they may or may not have been subjected to necessary processes (such as a ...

second embodiment

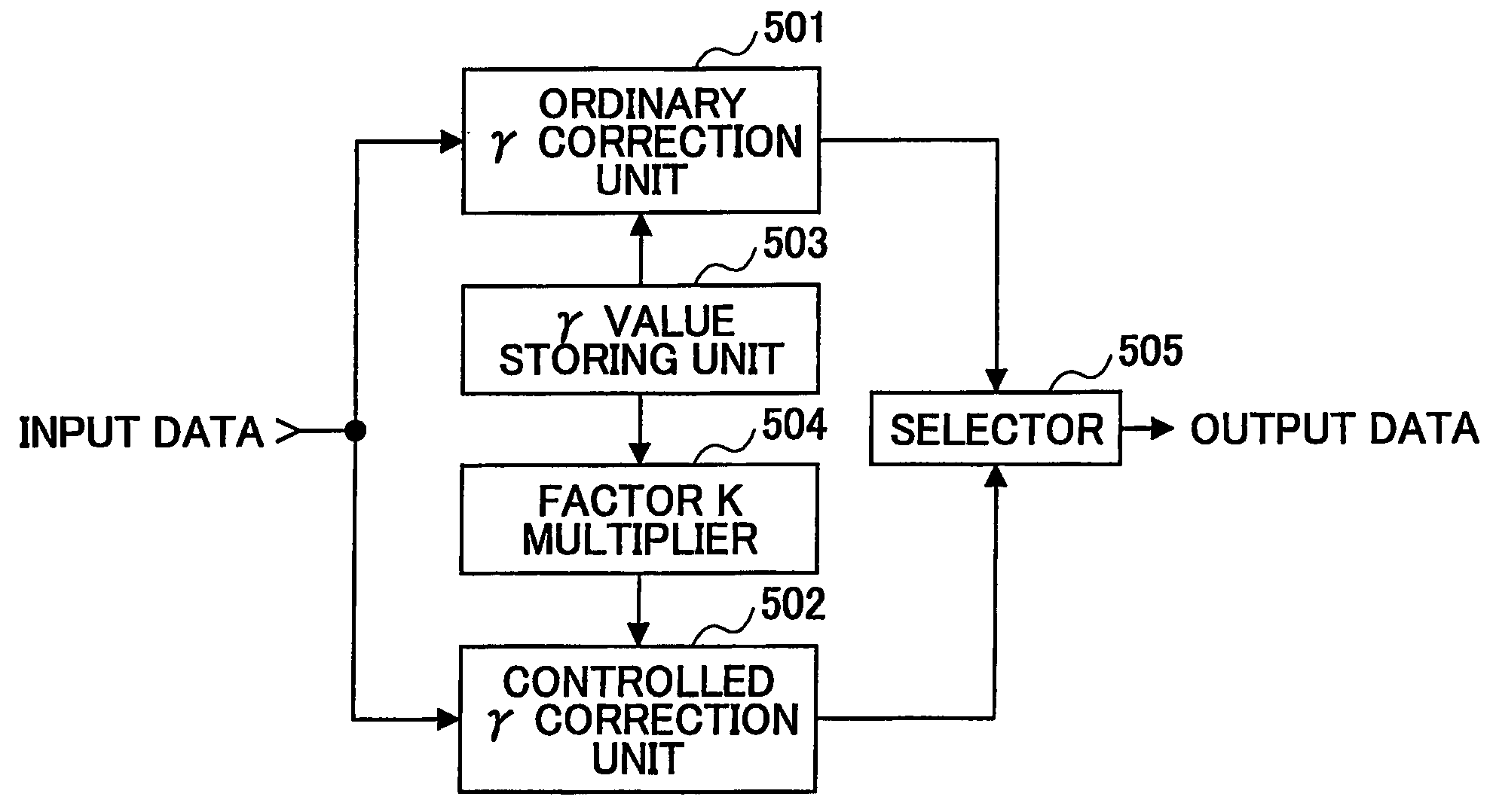

[0169]In the second embodiment, the controlled gamma correction unit 502 performs gamma correction on the input data using a controlled gamma value obtained by multiplying the ordinary gamma value by factor K (K502 is generally smaller than the ordinary gamma value, and therefore, the amount of ink adhering to paper is reduced.

[0170]By reducing the amount of ink (liquid) adhering to paper, leakage of electric charges caused by excessive amount of moisture on paper is prevented. Consequently, electrostatic attraction between the paper and the conveyor belt 33 is maintained appropriately, and paper is transported in a stable manner. In addition, the accuracy of the landing position of the ink droplet is maintained high, and the image quality is improved.

[0171]When an image is formed on paper held by electrostatic attraction by ejecting ink droplets or other types of liquid droplets onto the paper, the possibility of leakage of electric charge always exists due to the moisture of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com