Self-closing slide assembly with dampening mechanism

a self-closing, slide technology, applied in the field of sliding assemblies, can solve the problems of occupying valuable space within the cabinet or drawer structure of the slide mechanism, slamming the drawer against the cabinet structure and re-opening, and damage to the drawer structure or slide mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In the following detailed description, terms of orientation such as “top,”“bottom,”“upper,”“lower,”“front,”“frontward,”“rear,”“rearward,” and “end” are used to simplify the description of the context of the illustrated embodiments. Likewise, terms of sequence, such as “first” and “second,” are used to simplify the description of the illustrated embodiments. However, other orientations and sequences are possible, and the present invention should not be limited to the illustrated orientation(s). Those skilled in the art will appreciate that other orientations of the various components are possible.

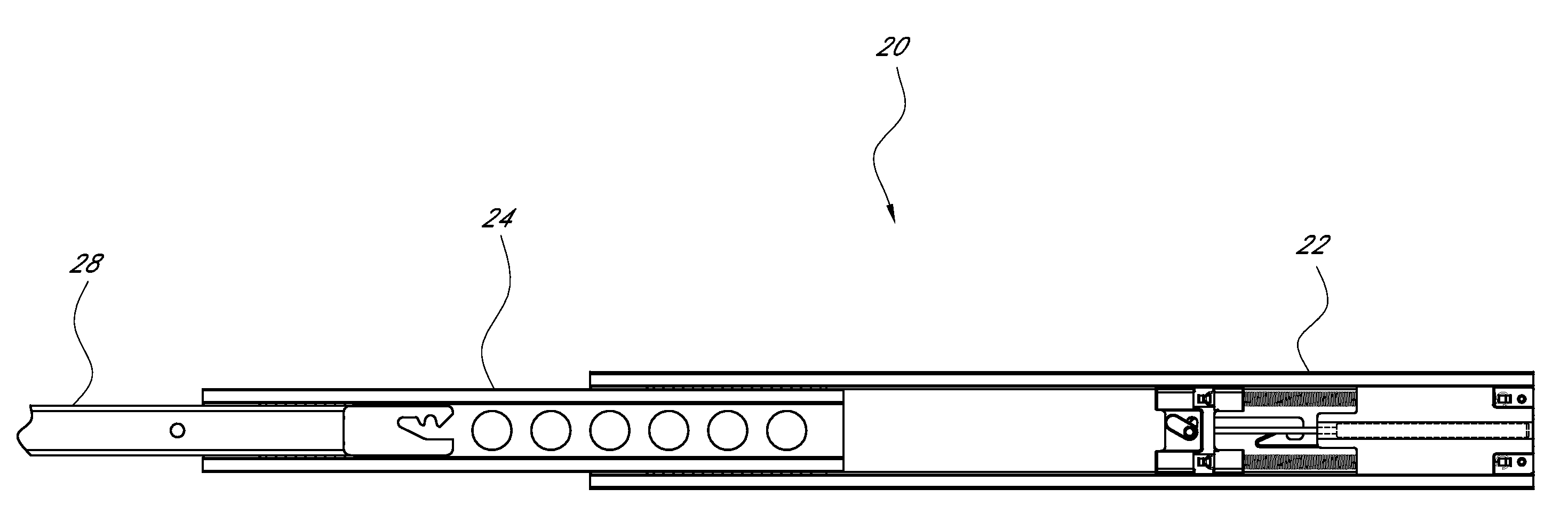

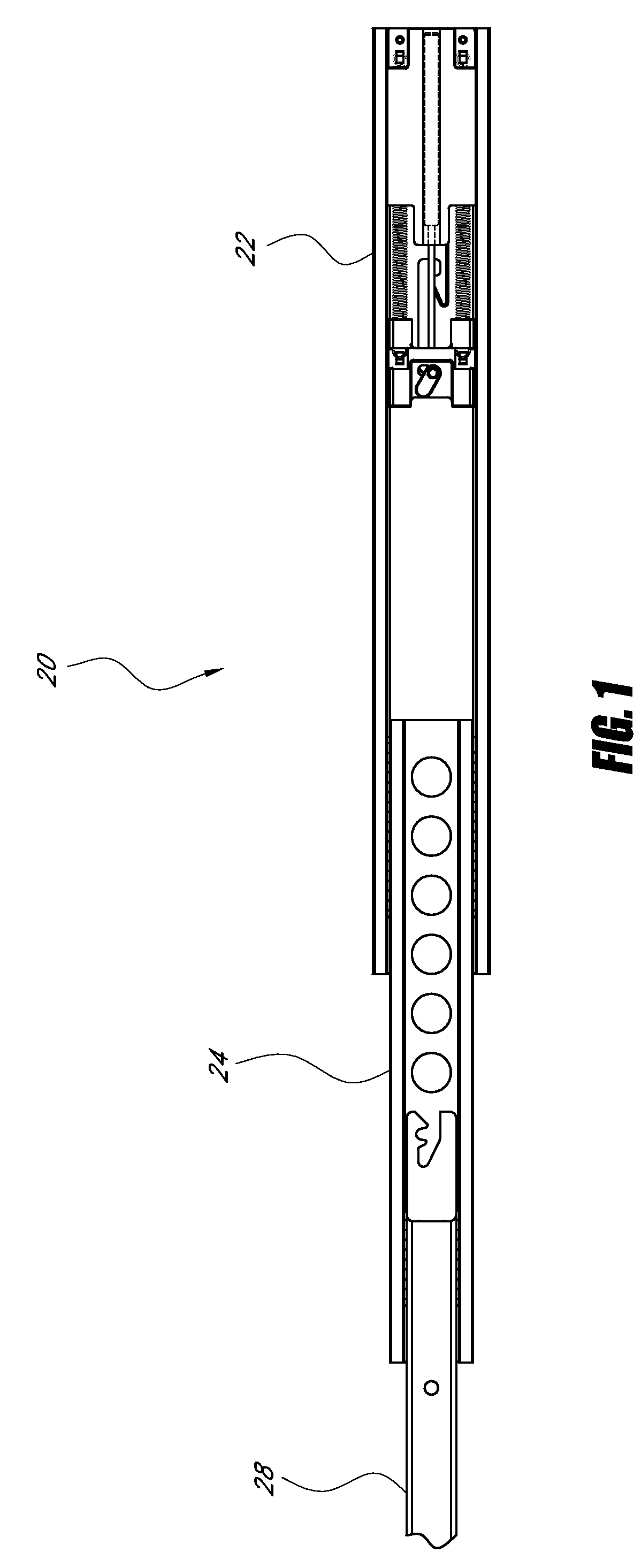

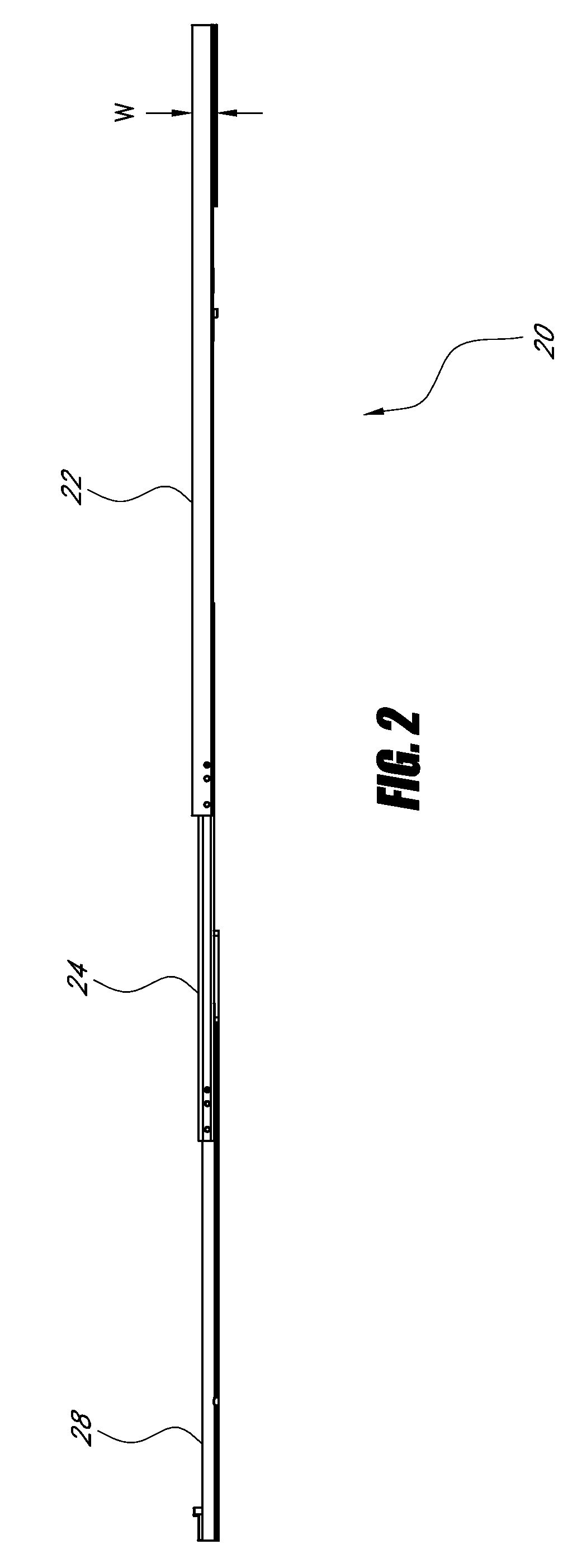

[0027]FIG. 1 illustrates an embodiment of a slide assembly 20 including an outer slide segment 22 and an inner slide segment 28 operably supported by the outer segment 22. The illustrated slide assembly 20 also includes an intermediate segment 24 interposed between the outer slide segment 22 and the inner slide segment 28. In other arrangements, the slide assembly 20 can include one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com