Shotgun shoulder stock shell carrier

a shoulder stock and shotgun technology, applied in the direction of ammunition loading, butts, weapons, etc., can solve the problems of affecting the storage of additional shells,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

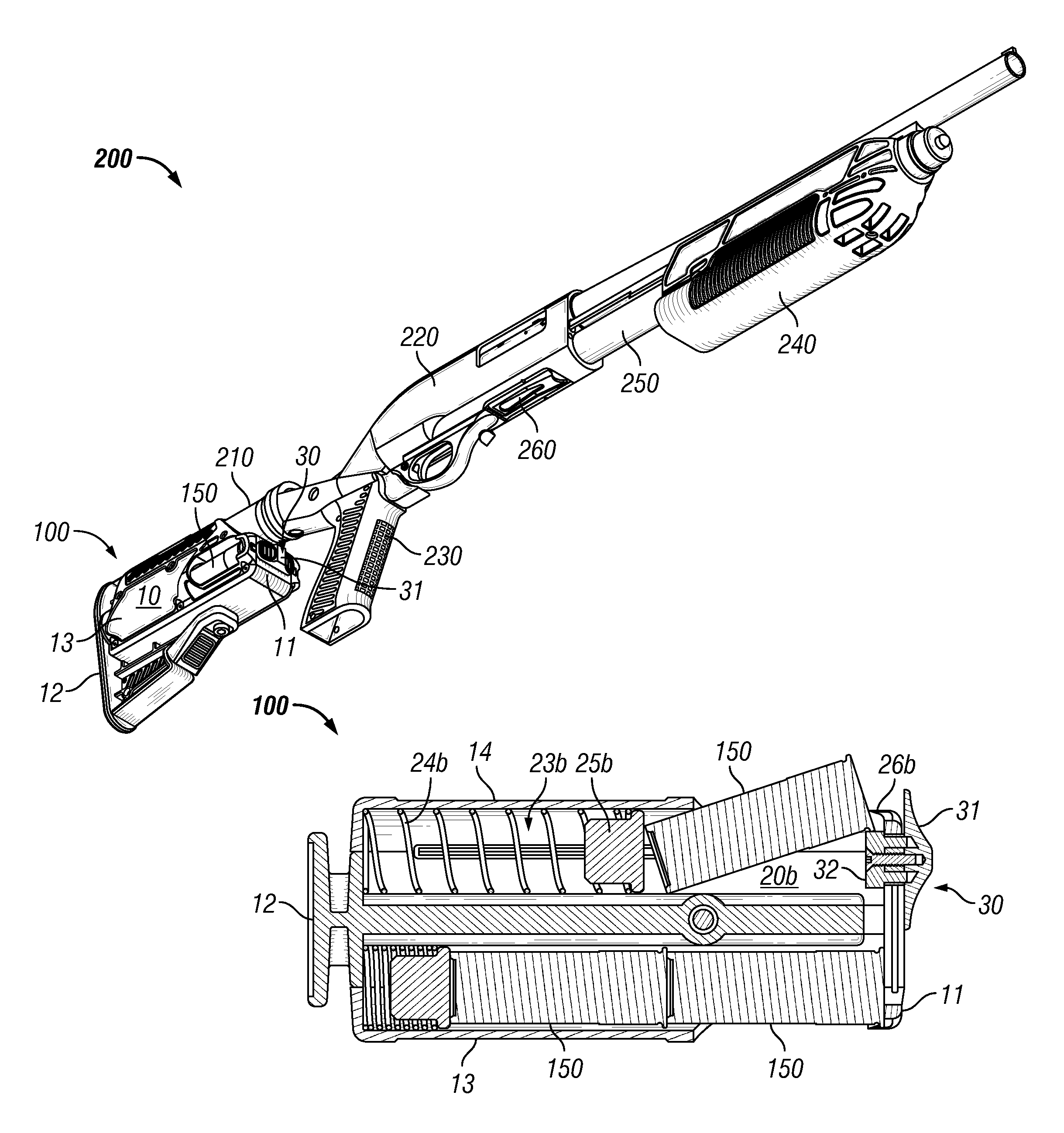

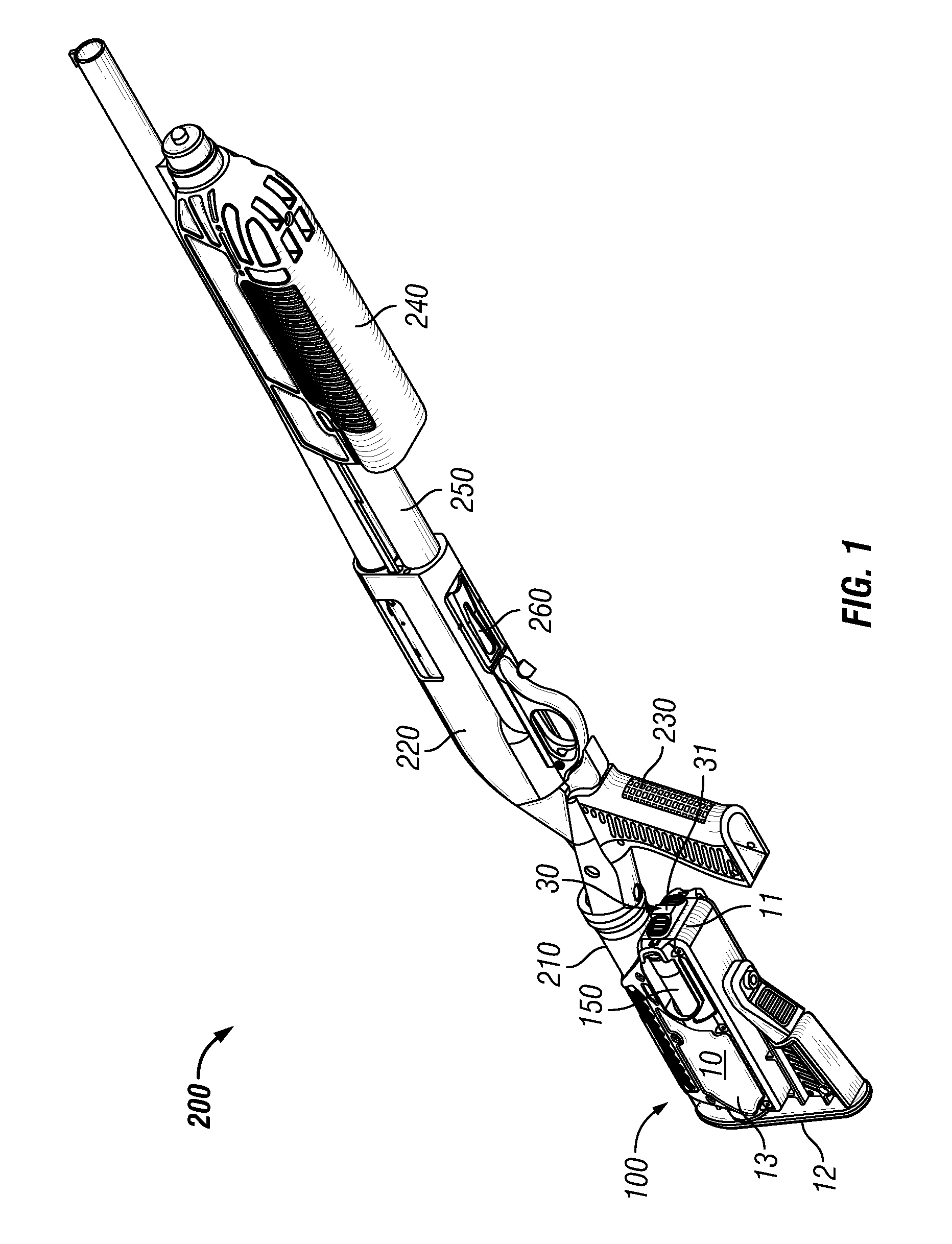

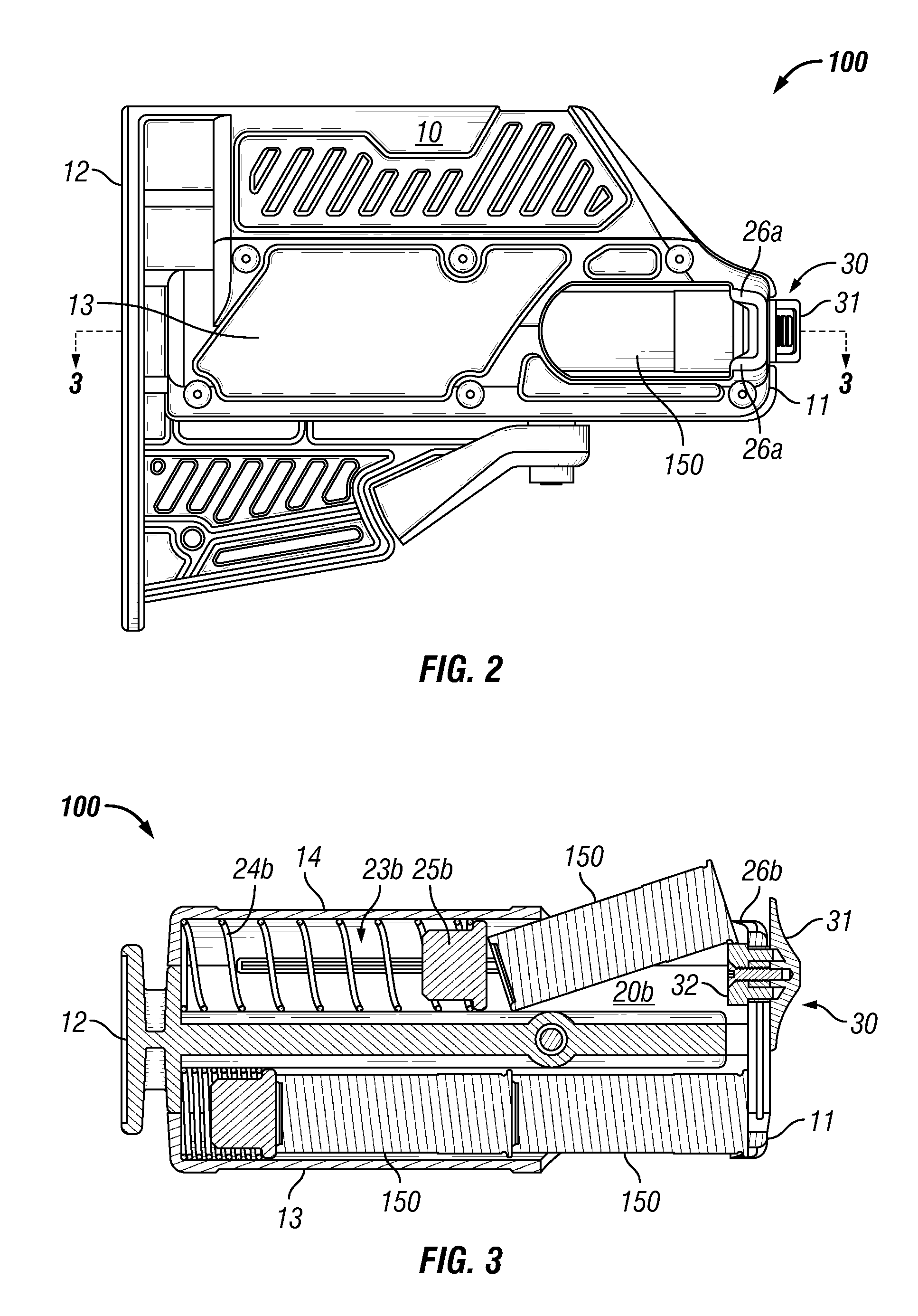

[0024]FIG. 1 shows a shotgun 200 that includes a rear stock 100 connected to the shotgun 200 via a telescoping tube 210. The rear stock 100 is adapted to telescope on telescoping tube 210 to change the overall length of the firearm as would be appreciated by one of ordinary skill in the art. The rearward end 12 of the rear stock 100 is adapted to engage the shoulder of a person operating the shotgun 200. The operator may grip the pistol grip 230 of the shotgun 200 with one hand and position the other hand on a forward position of the shotgun, such as on the forend 240. Shotgun shells, also referred to herein as shot shells, 150 may be loaded into a magazine tube 250 via port 260 and the magazine tube 250 may be actuated to load a shot shell 150 into the receiver 220, as would be appreciated by one of ordinary skill in the art. The forend 240 may include the capacity to hold shot shells 150 such as the forend disclosed in U.S. Pat. No. 8,122,635 and U.S. Pat. No. 8,353,123, both of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com