System for fastening a rail in place and fastening for a rail

a technology of rails and fastening devices, applied in the direction of railway tracks, roads, constructions, etc., can solve the problem that the fastening process requires maintenance after only a comparatively short period of operation, and achieve the effect of minimising the emitted sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

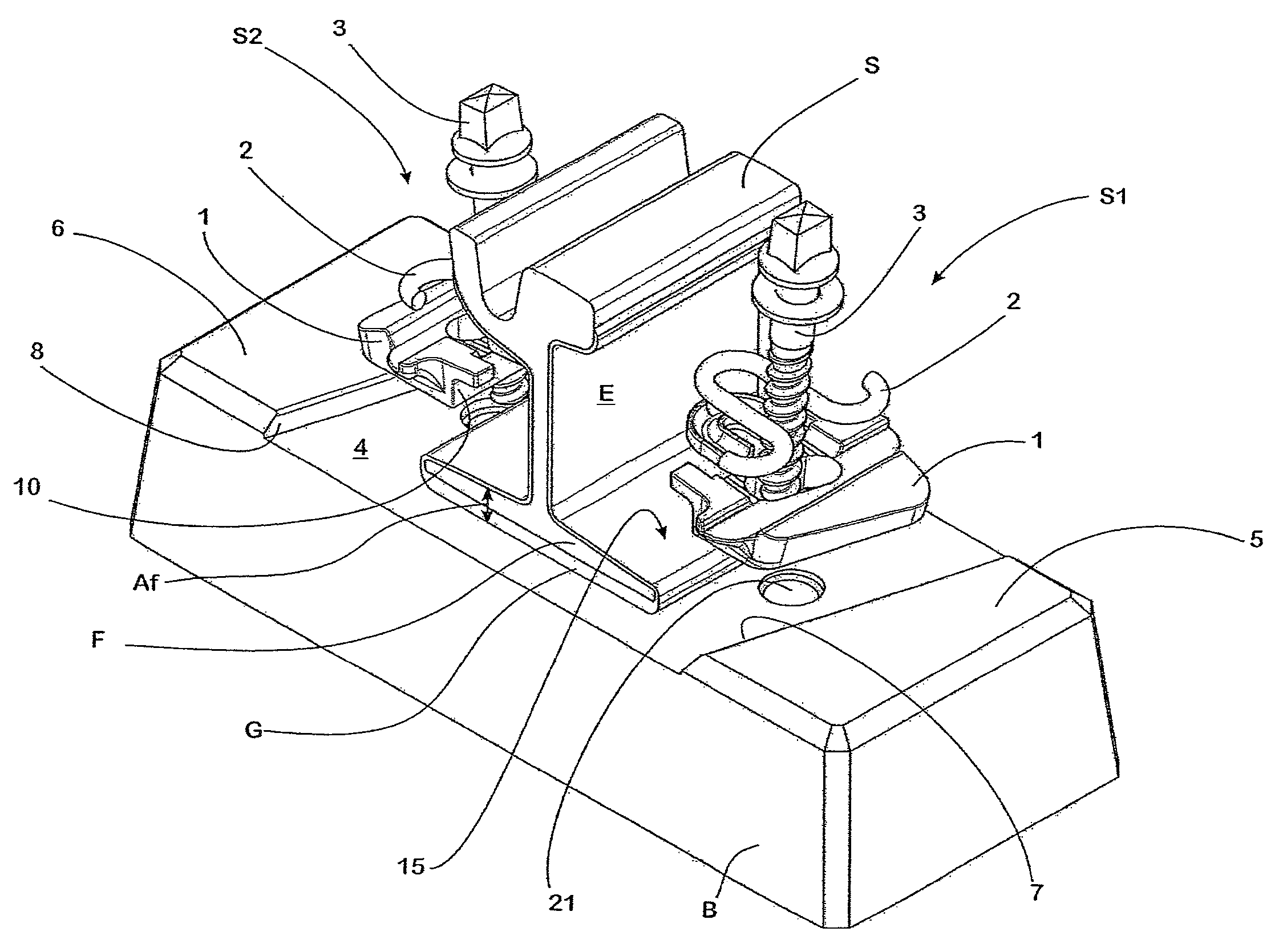

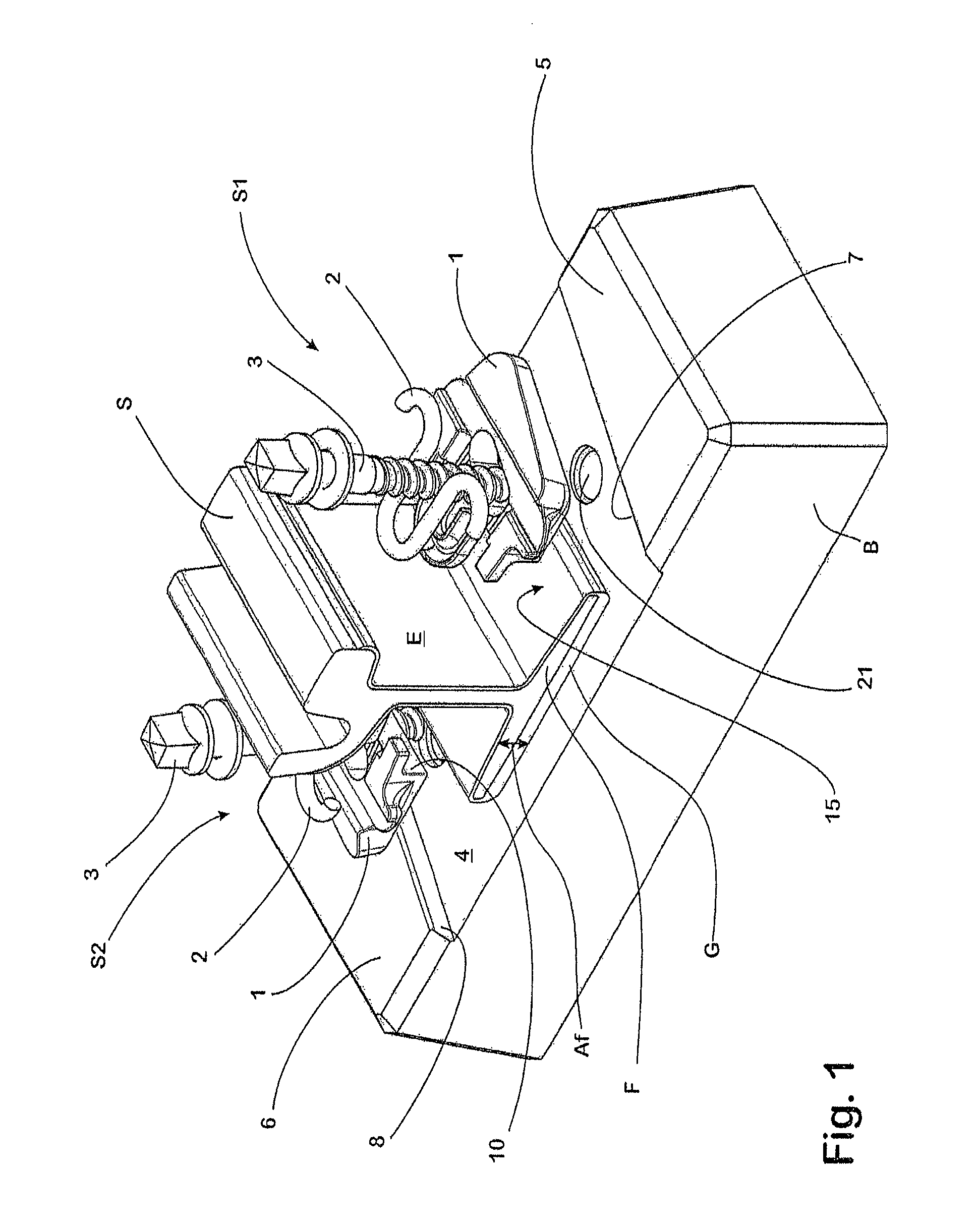

[0045]The rail S takes the form of a type of grooved rail and the fastening thereof to a solid base formed by a concrete sleeper B is accomplished by means two systems S1, S2 of similar design which each comprise a guide plate 1, a resilient member 2 and, as a clamping member, a clamping screw 3.

[0046]Formed in the concrete sleeper B is a plane supporting surface 4 which, at its longitudinal edges, meets the longitudinal sides of the sleeper B and which is bounded by respective shoulders 5, 6 at its narrow sides. The contacting surfaces 7, 8 of the shoulders 5, 6, which are associated with the supporting surface 4 and extend parallel to one another, each meet the longitudinal edges of the supporting surface 4 at an acute angle, thus giving the supporting surface 4 the form of a parallelogram in plan.

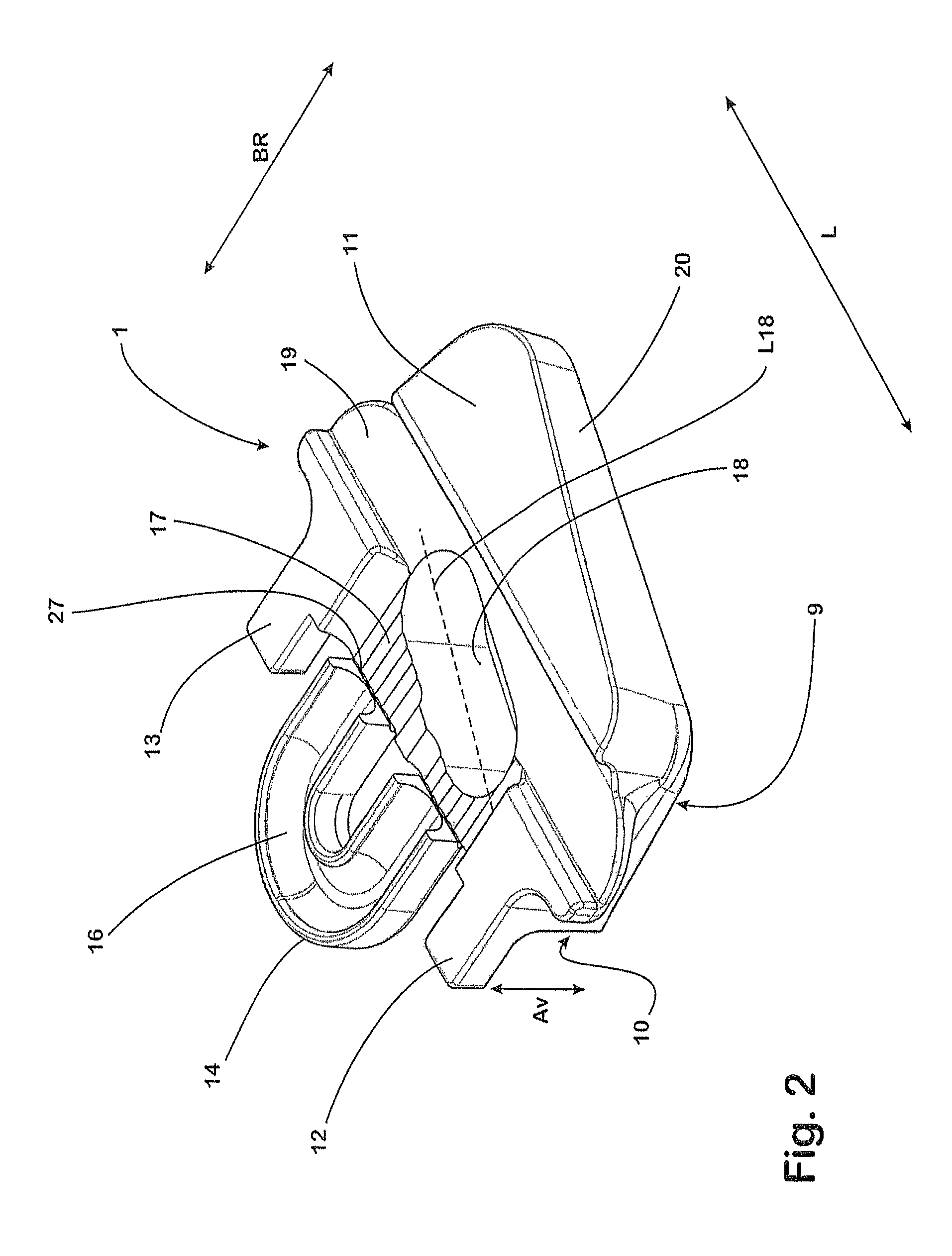

[0047]Each guide plate 1, which is made of a non-conductive plastics material which is for example fibre-reinforced, has on its underside a supported surface 9 by which it rests on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com