Method for automatic controlling thickness in fast high precision plate strip rolling process

A high-precision, plate-and-strip technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as the influence of speed changes on control quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

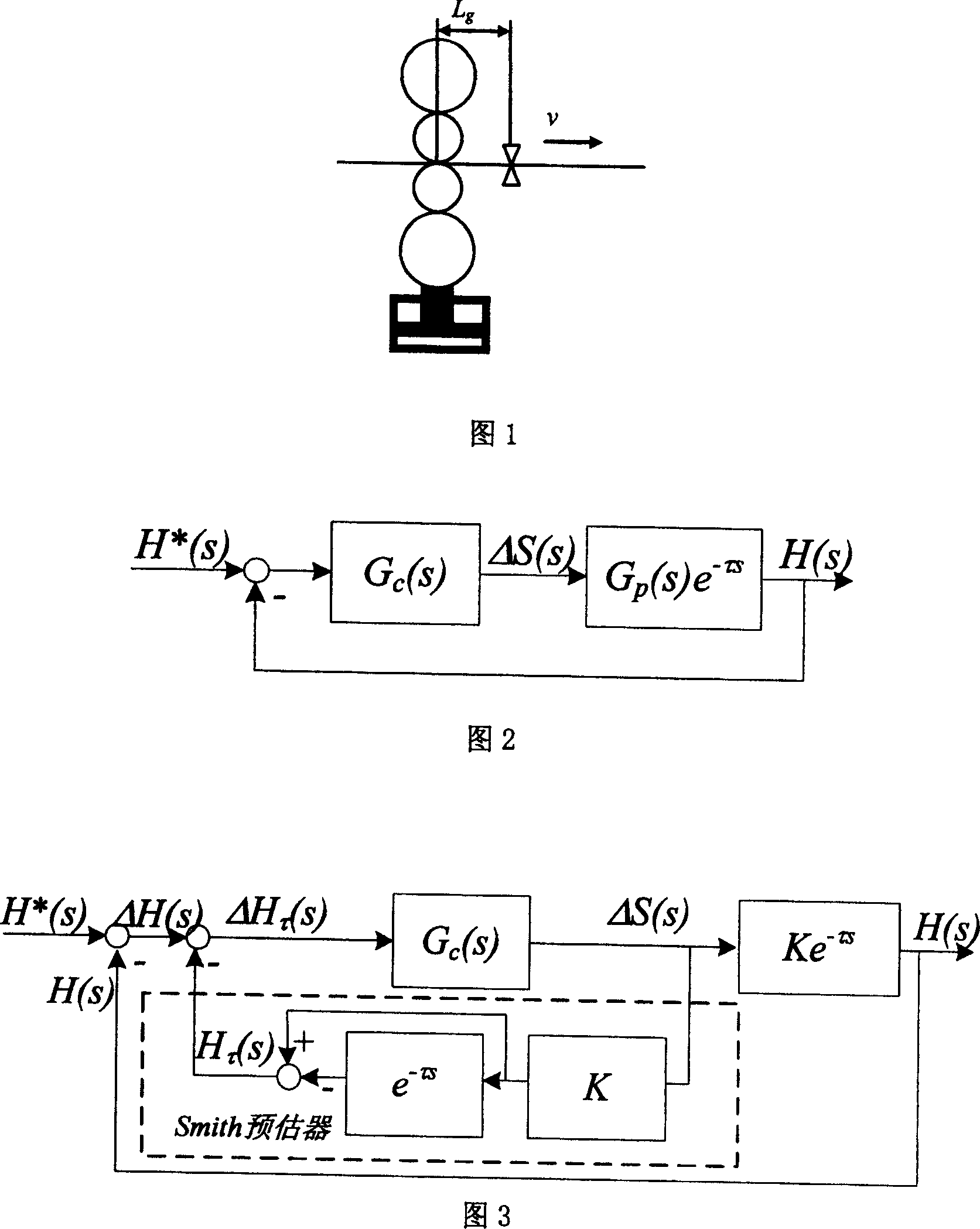

Problems solved by technology

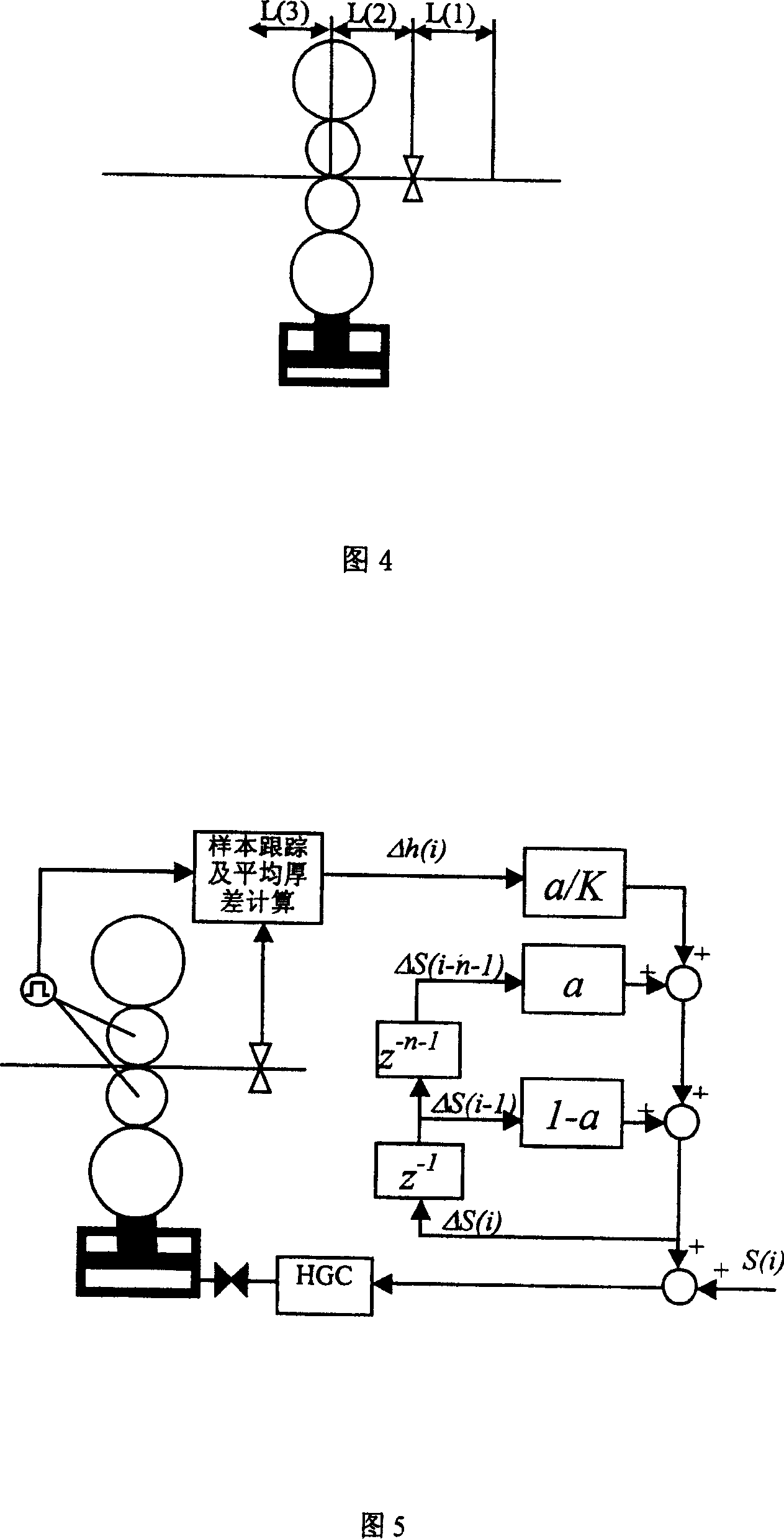

Method used

Image

Examples

example 1

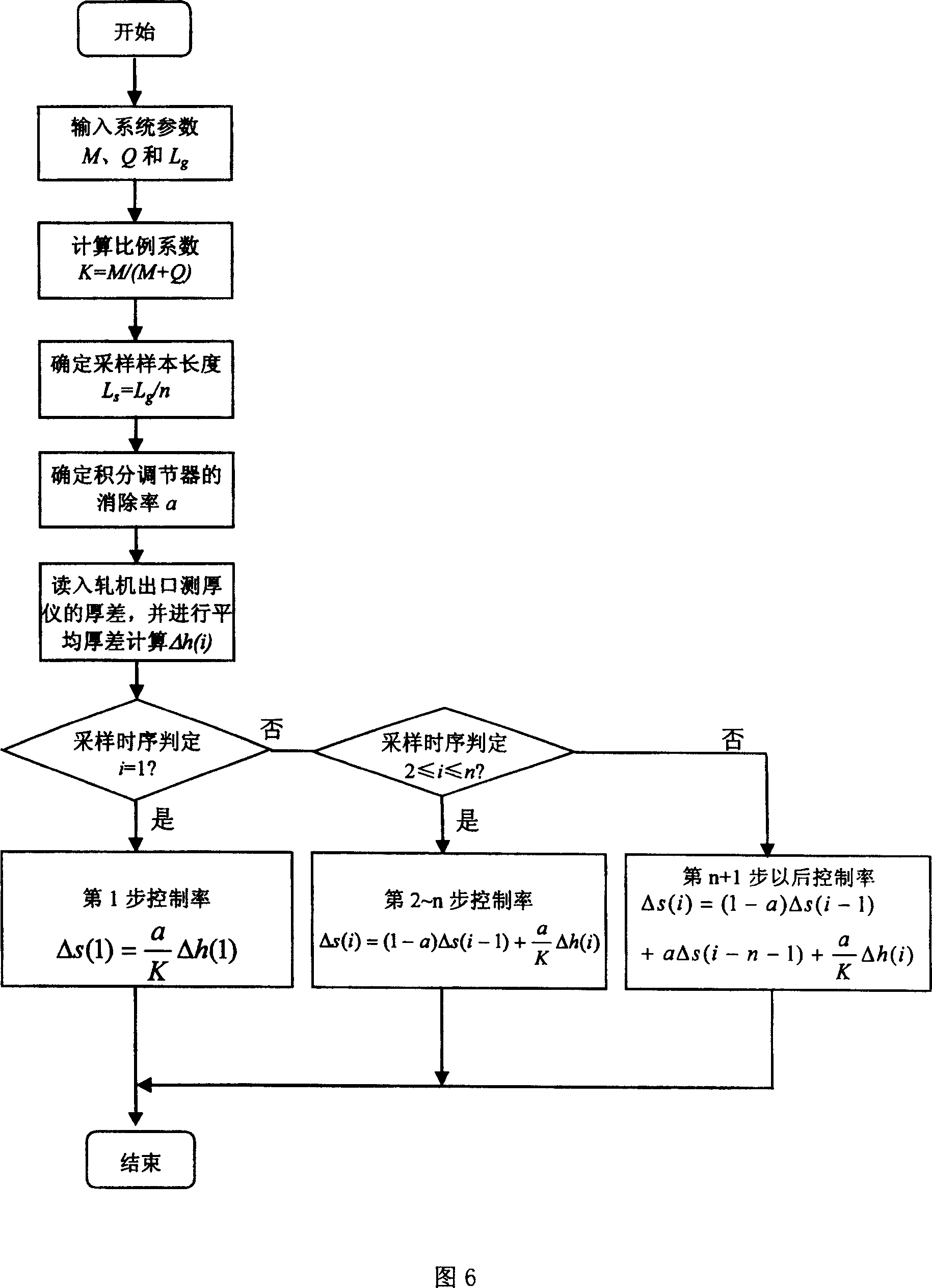

[0094] A single-stand four-high reversible experimental rolling mill is used, and the relevant parameters of the system are as follows:

[0095] Rolled steel grade: ST12

[0096] Incoming material thickness width 250mm, 0.50mm, outlet thickness 0.40mm, rolling speed 2.5m / s

[0097] Rolling mill stiffness M = 550kN / mm, strip plastic coefficient Q = 450 kN / mm

[0098] The thickness gauge is a VOLLMER contact thickness gauge, and the distance between the thickness gauge and the roll center line of the rolling mill is L g =765mm

[0099] The monitoring AGC control parameters and methods based on the above conditions are as follows:

[0100] 1) Input the relevant data of the four-high reversible rolling mill and strip steel into the computer, the stiffness coefficient of the rolling mill M = 550kN / mm, the plasticity coefficient of the strip steel Q = 450kN / mm, the distance L between the thickness gauge and the roll center line of the rolling mill g =765mm;

[0101] 2) Determin...

example 2

[0117] The four-high reversing rolling mill of the cold strip mill is adopted, and the relevant parameters of the system are as follows:

[0118] Rolled steel grade: 65Mn

[0119] Incoming material width 130mm, thickness 1.0mm, exit thickness 0.80mm, rolling speed 3.0m / s

[0120] The parameters of the four-high reversible rolling mill are as follows: rigidity M = 400kN / mm, plasticity coefficient Q of the strip steel = 500kN / mm

[0121] The thickness gauge is a domestic contact type thickness gauge, and the distance between the thickness gauge and the center line of the rolling mill roll is L g =500mm

[0122] The monitoring AGC control parameters and methods based on the above conditions are as follows:

[0123] 1) Input the relevant data of the four-high reversible rolling mill and strip steel into the computer, the stiffness coefficient of the rolling mill M = 400kN / mm, the plasticity coefficient of the strip steel Q = 500kN / mm, the distance L between the thickness gauge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com