Plate strip hot continuous rolling reeling temperature control method based on thermodetector

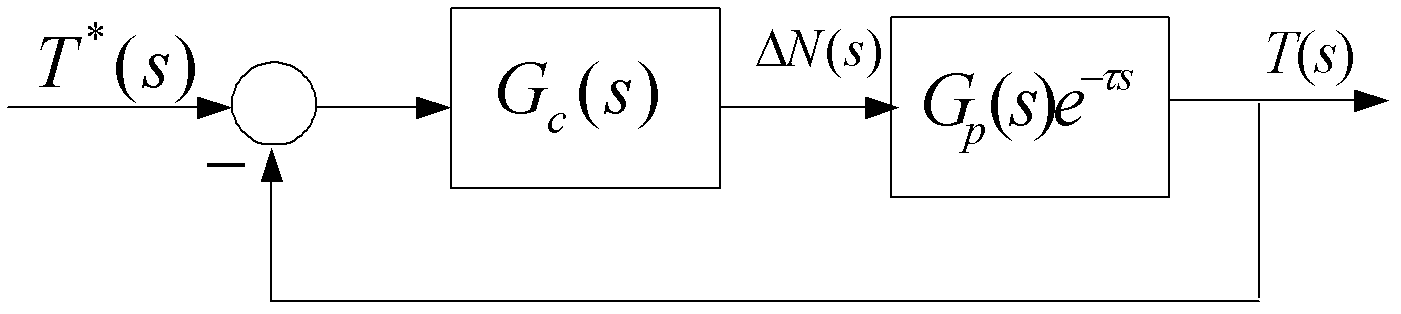

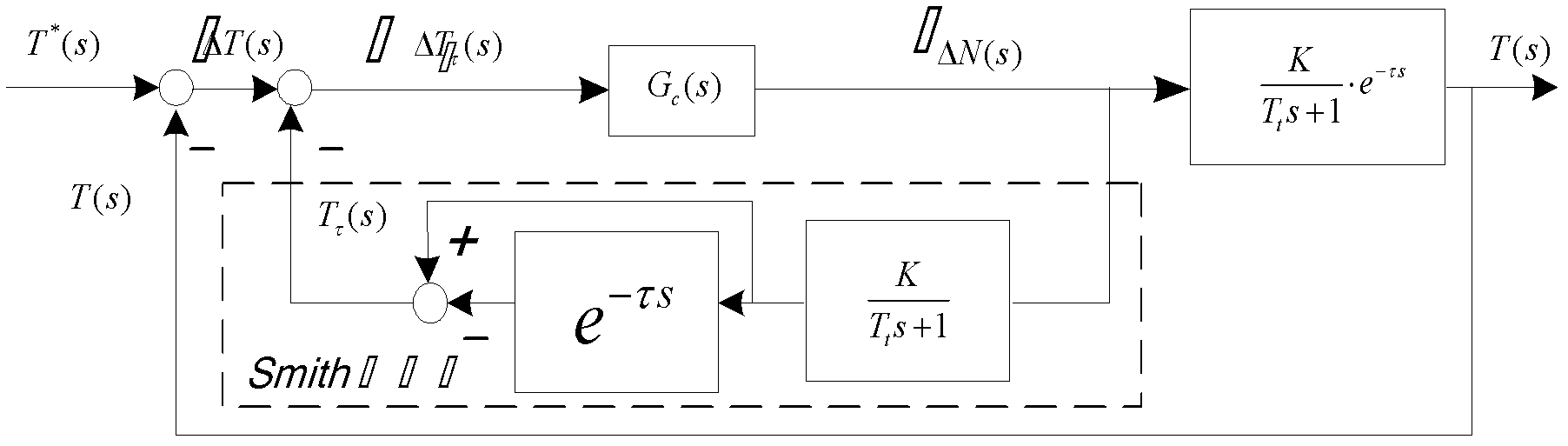

A technology of coiling temperature and control method, applied in the direction of temperature control, etc., can solve the problems of system over damping or oscillation, failure to give optimal control law, poor control effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

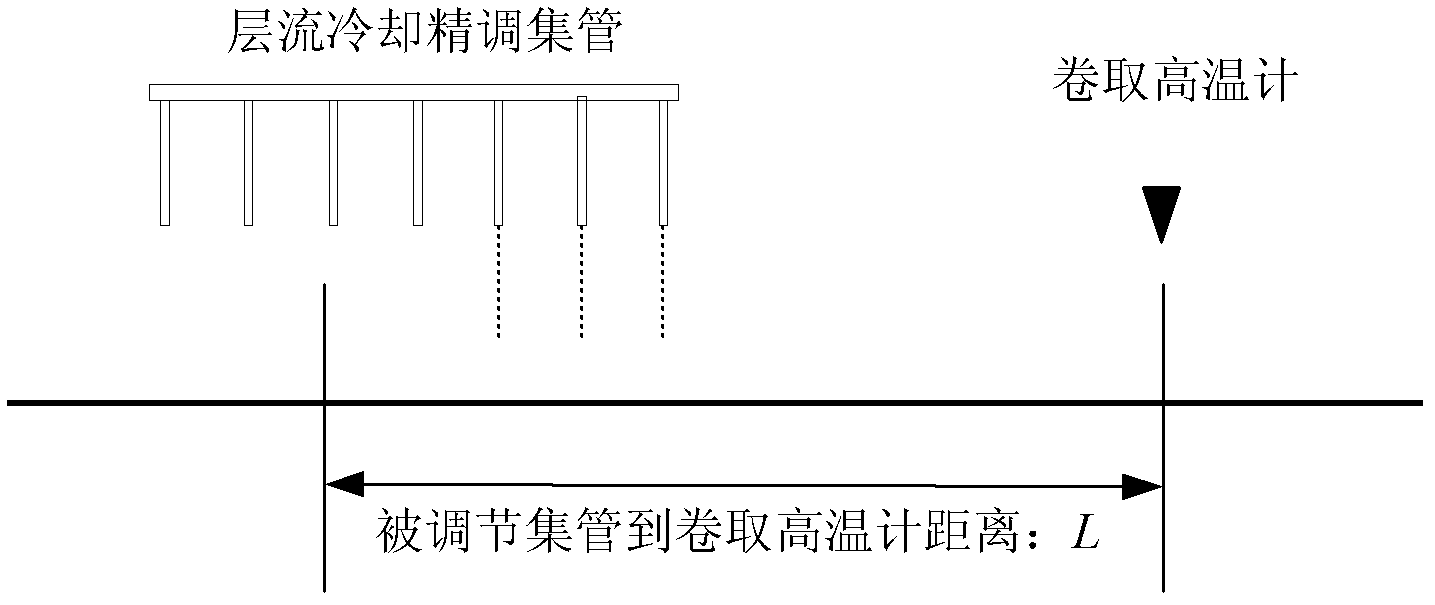

[0124] In this embodiment, the rolling steel type is selected as Q235B, the incoming material thickness is 6.0mm, the rolling speed is 8.0m / s, the specific gravity is 7850kg / m3, and the specific heat is 0.812kJ / (kg·℃); The length is 0.585m; the distance from the thermometer to the header that needs to be opened and closed is 6m; the heat flux density of each finely adjusted header is 6665304.81kJ / (m2.h); the time required for the opening and closing of the control valve and the water falling to the strip steel 700ms;

[0125] In this embodiment, a method for controlling the coiling temperature of strip hot rolling based on a thermometer, such as Figure 7 shown, including the following steps:

[0126] Step 1: Input the relevant data of cooling equipment and steel strip into the computer, the thickness of the incoming material is 6.0mm, the rolling speed is 8.0m / s, and the heat flux density of each fine-tuned header is 6665304.81kJ / (m 2 .h), specific gravity 7850kg / m 3 , the...

Embodiment 2

[0146] In this embodiment, the rolling steel grade is selected as Q345B, the thickness of the incoming material is 4.0mm, the rolling speed is 10.0m / s, the specific gravity is 7850kg / m3, and the specific heat is 0.7985kJ / (kg·℃); The length is 0.4m; the distance from the thermometer to the header that needs to be opened and closed is 5.8m; the heat flux density of each fine-tuned header is 6665304.81kJ / (m2.h); the opening and closing of the control valve and the water falling to the strip require The time is 700ms;

[0147] In this embodiment, a method for controlling the coiling temperature of strip hot rolling based on a thermometer comprises the following steps:

[0148] Step 1: Input the relevant data of cooling equipment and strip steel into the computer, select the rolling steel type: Q345B, the incoming material thickness is 4.0mm, the rolling speed is 10.0m / s, and the heat flux density of each fine-tuned header is 6665304.81kJ / (m 2 .h), specific gravity 7850kg / m 3 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com