Automatic-boosting reciprocating pump

A reciprocating pump, automatic technology, applied in the field of reciprocating pumps, can solve problems such as insufficient boost ratio, easy leakage, insufficient displacement, etc., to achieve uniform flow, increase boost level, and increase displacement level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

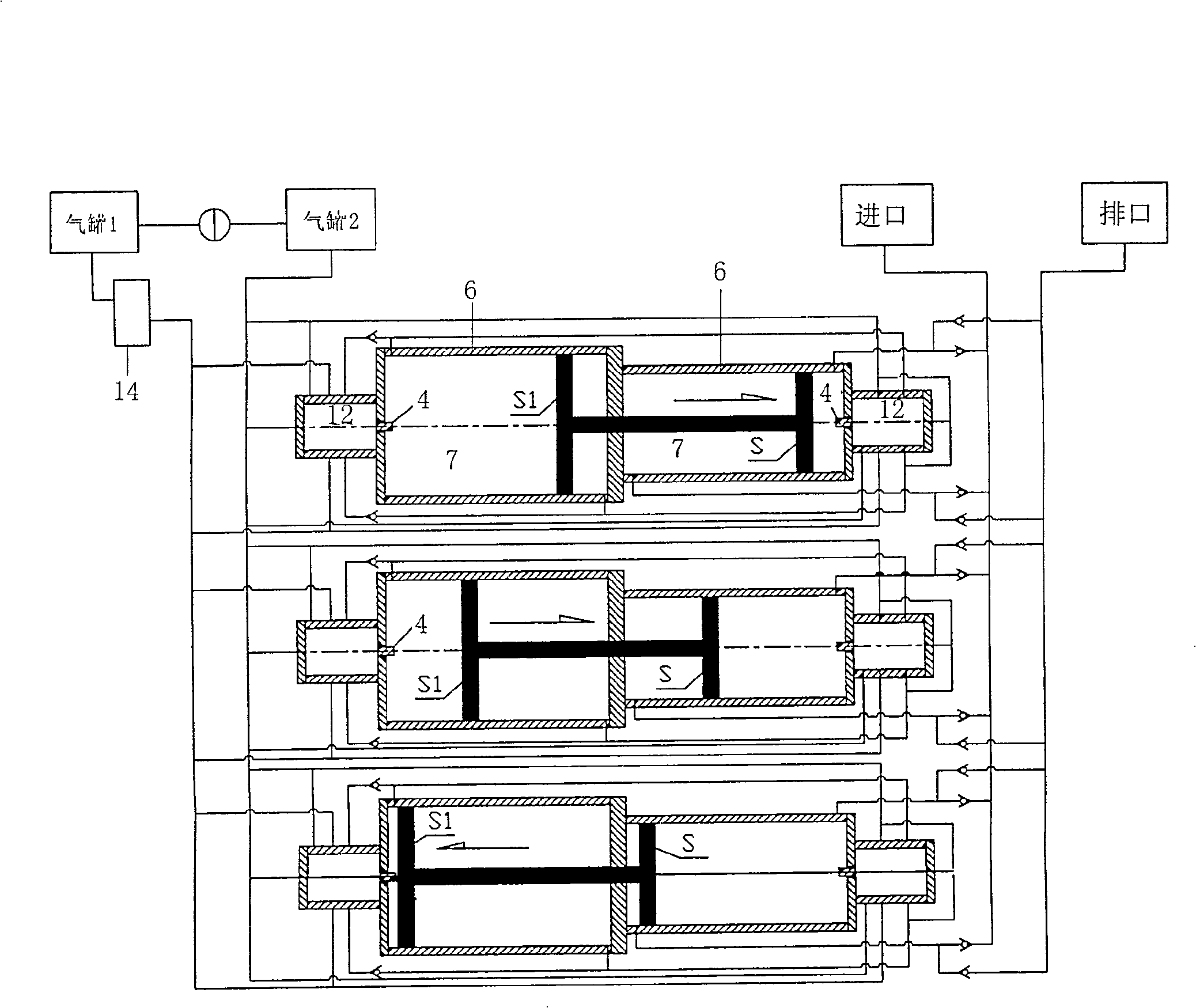

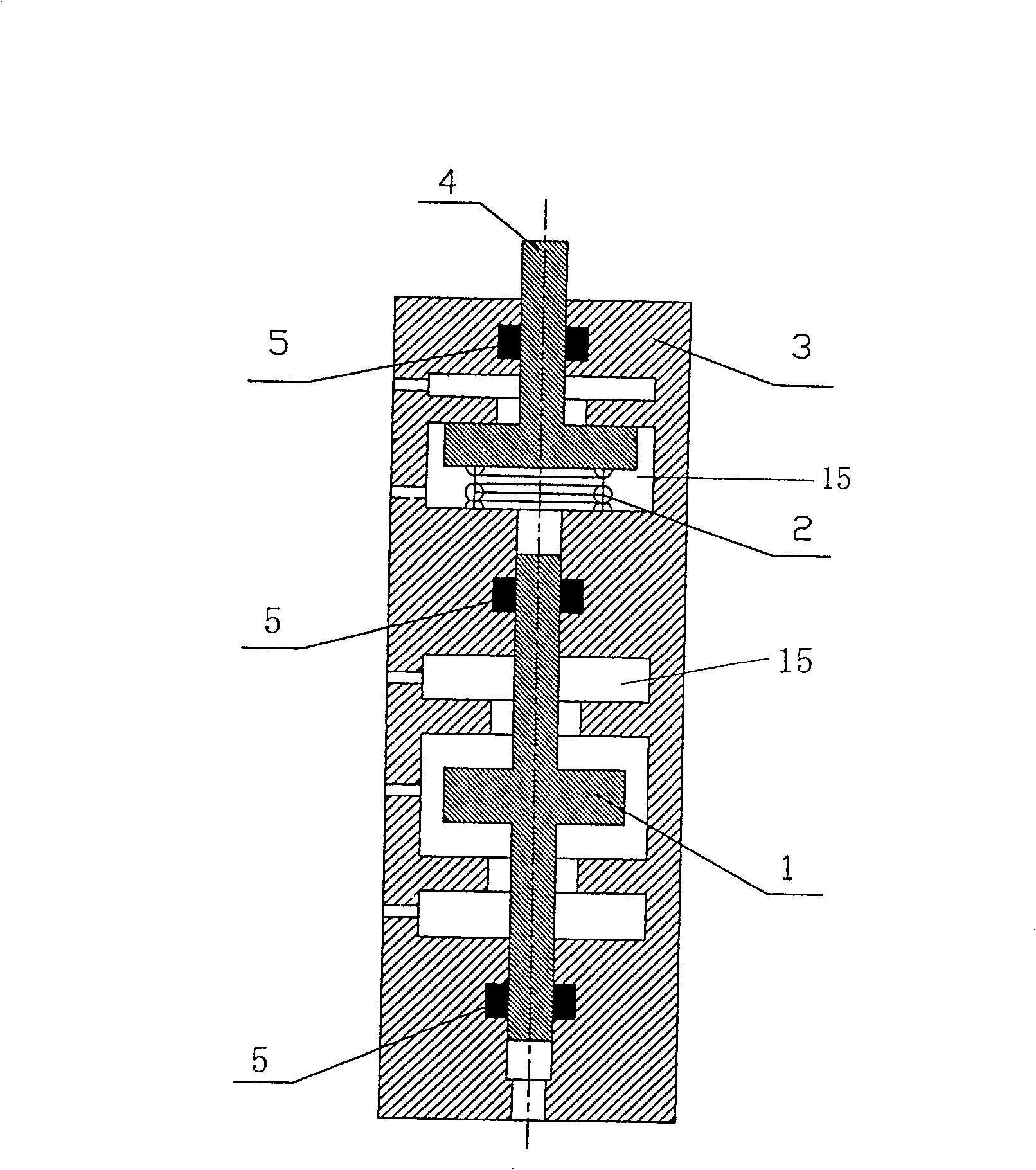

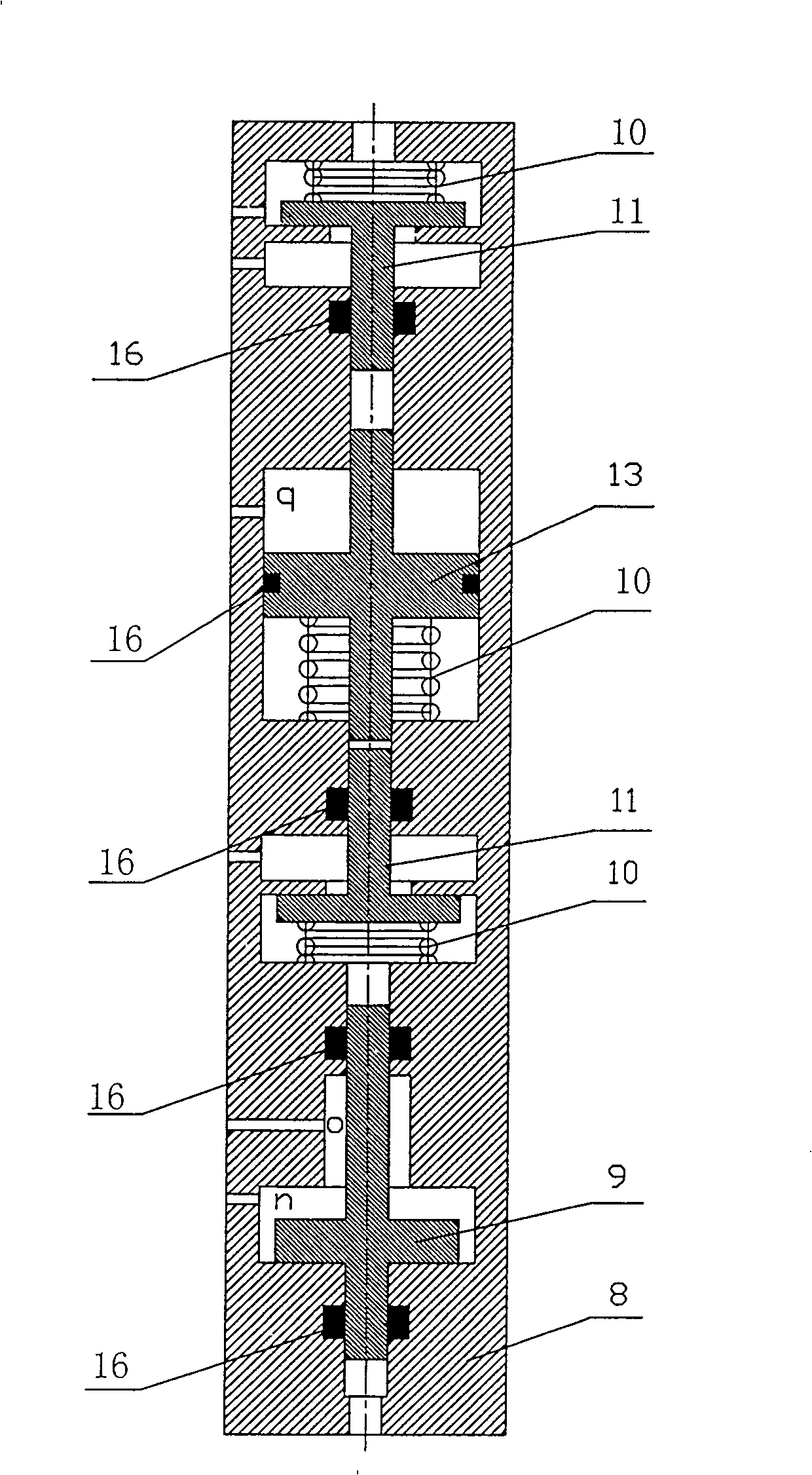

[0028] Below in conjunction with accompanying drawing, specific structure of the present invention is described in detail as follows:

[0029] Such as Figure 1-3 As shown, one of the combined use forms of series and parallel in its working principle: two-stage series and three sets of parallel structure is used as an example for specific description, and three sets of booster reciprocating devices are set, and the booster reciprocating devices are: The two-pole cylinders 6 are connected in series on the same axis line, the pistons of the cylinders 6 are arranged in the cylinder cavity 7, and the two ends of the cylinders 6 connected in series are respectively provided with an automatic control switching direction valve group 12, and the automatic control switching direction One end of the contact 4 of the valve group 12 is arranged at both ends of the cylinder cavity 7, and a spring 2 is arranged between the other end of the contact 4 and the inner cavity 15 of the housing 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com