No- wear scissors for hair cut and the like application occasions

A technology of scissors and occasions, applied in the direction of metal processing, etc., can solve the problems of damage, cost of time and expense, unsatisfactory, etc., and achieve the effect of brisk movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

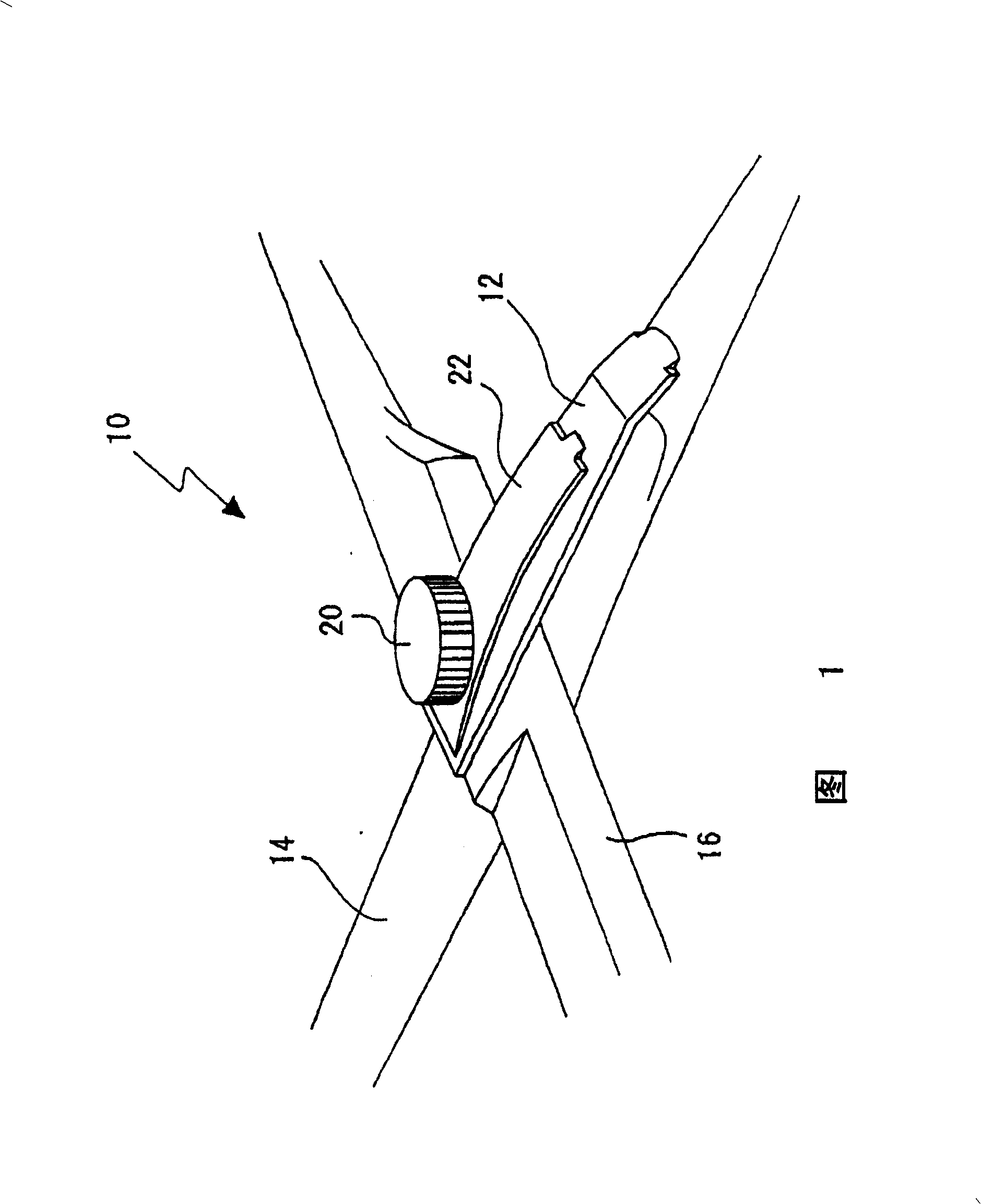

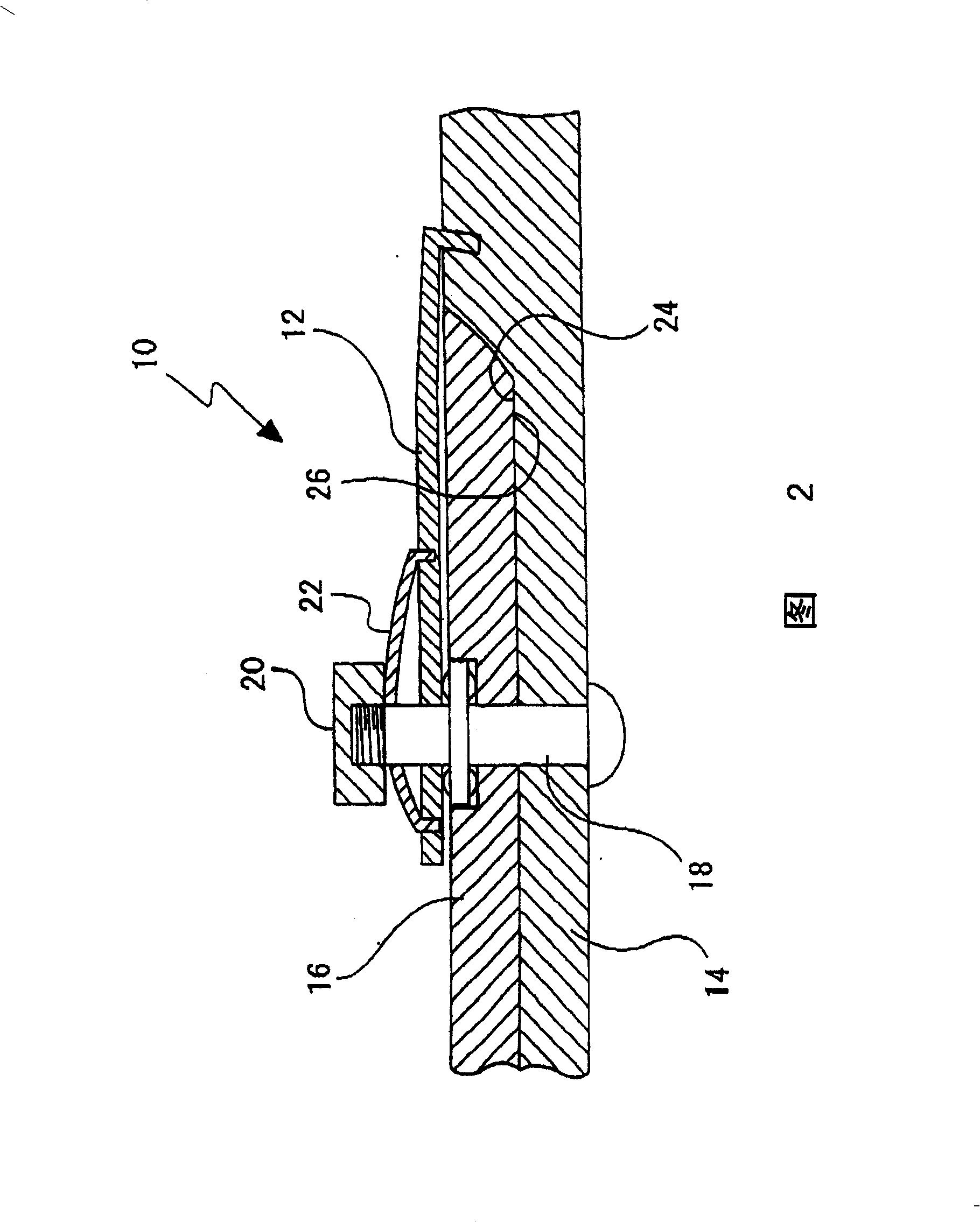

[0026] Careful examination of the above-mentioned prior art spring-assisted scissors according to Japanese Unexamined Patent Publication No. 11-244550 will help to better understand the features and advantages of the disclosed blade scissors. Referring to Figures 1 and 2, prior art scissors 10 have a cantilever spring 12 with a bent end embedded in the handle end of a blade 14, the other end being held against the other blade 16 and drilled. , to fit on a bolt 18 that pivotally connects the two blades 14 and 16 . A cover nut 20 is provided on the fastening bolt 18, and the blades 14 and each other are pressed together by the cantilever spring 12 and an adjusting leaf spring 22.

[0027] Being spring-loaded as described above, the prior art scissors require minimal additional force from the operator to maintain the contact areas 24 and 26 of the blades 14 and 16 in sliding engagement with each other during cutting. Sooner or later, these contact areas 24 and 26 will wear down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com