Safe airbag with vertical groove

A technology of airbags and inflatable chambers, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle components, etc., can solve the problems of adding components, increasing the risk of component failure, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

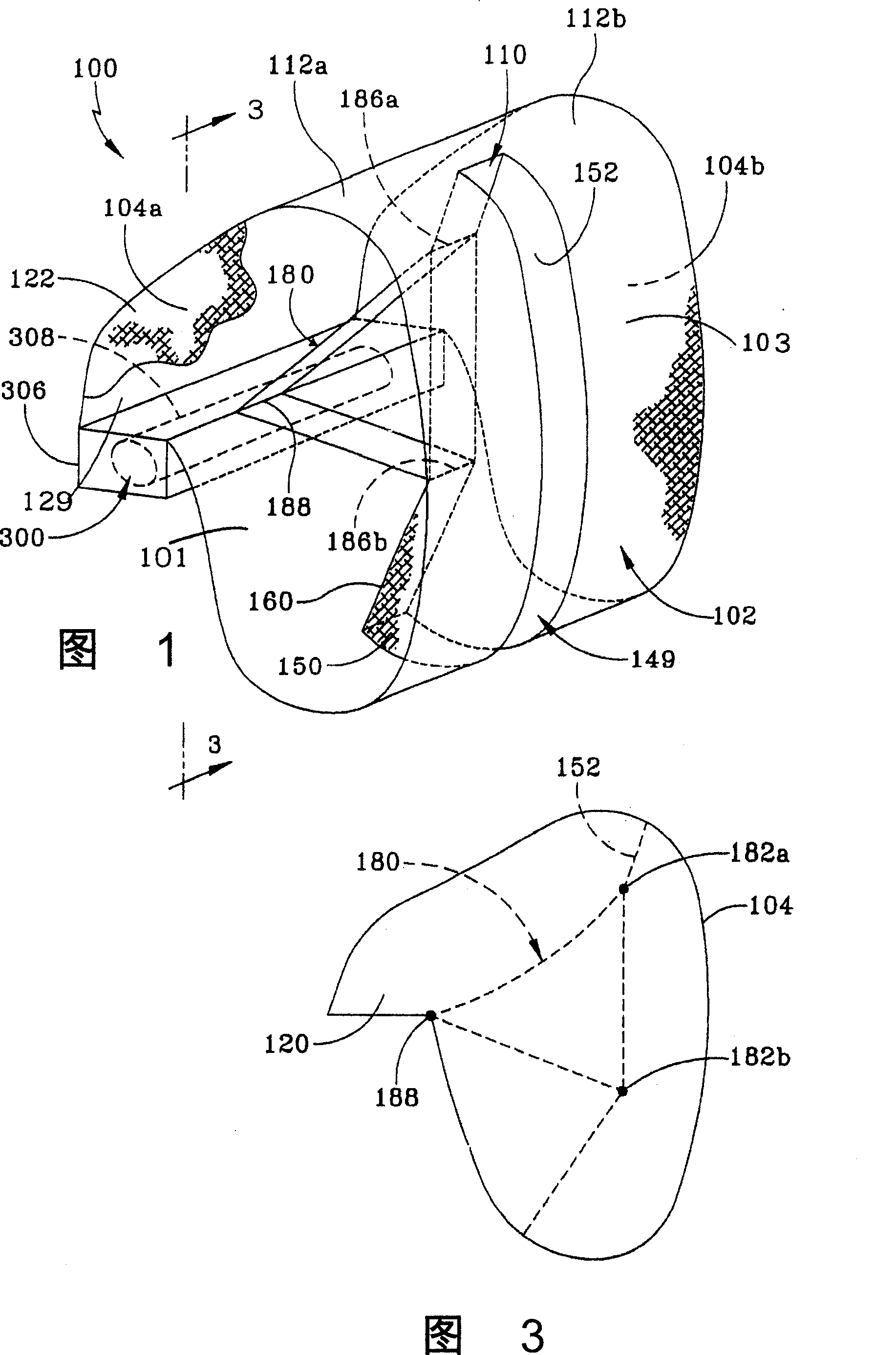

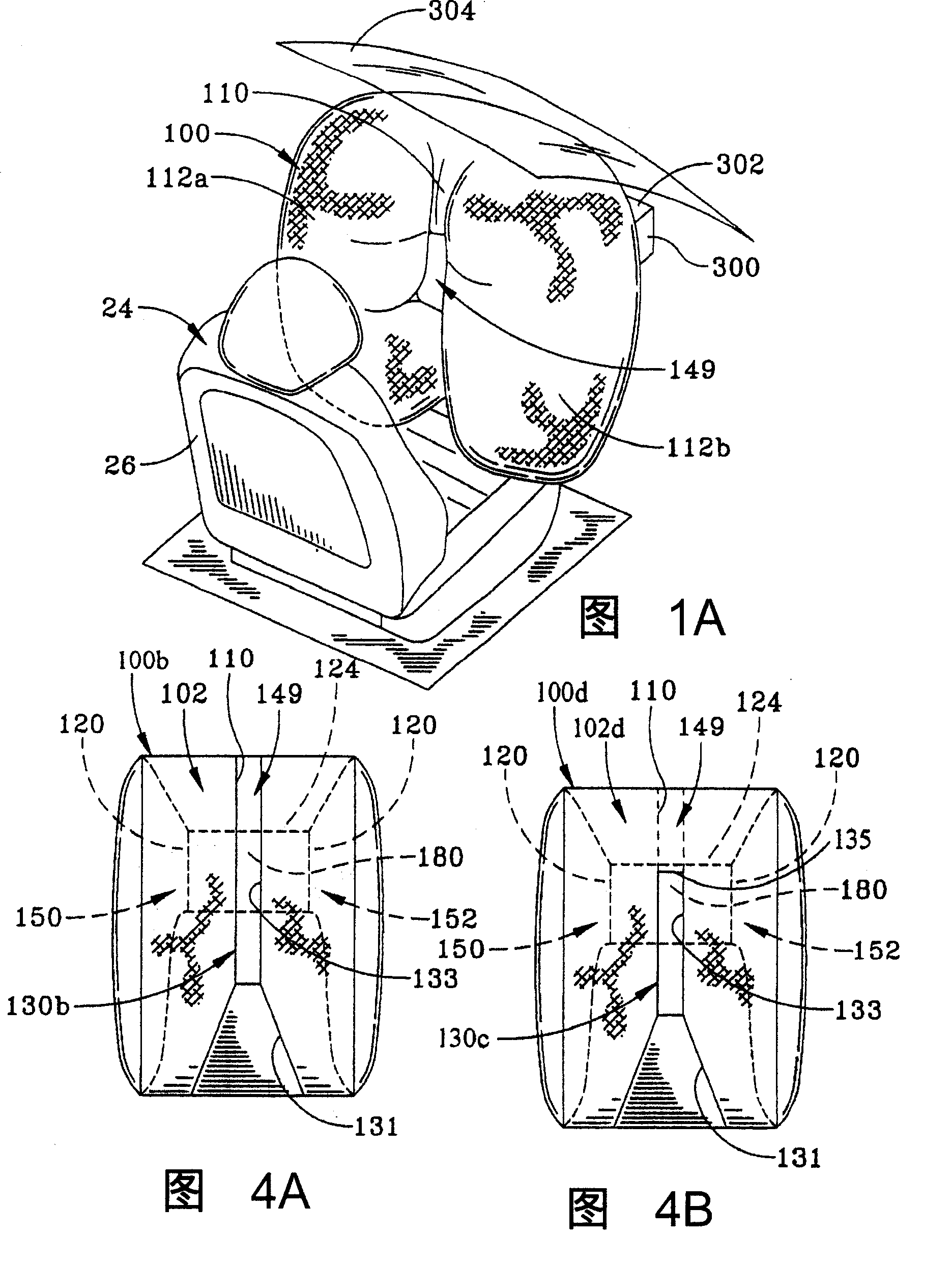

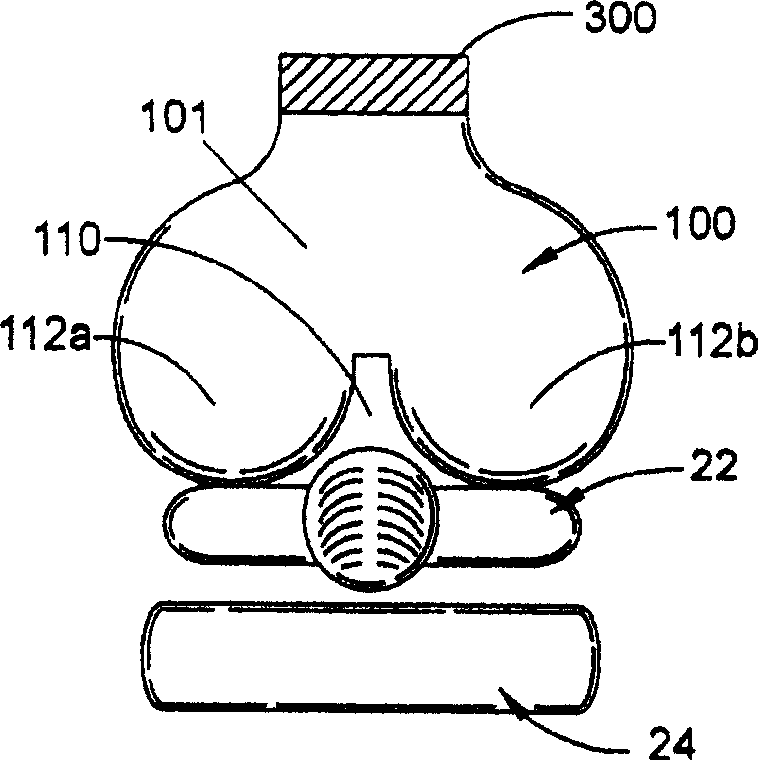

[0034] Figures 1-6 show an airbag having a single inflation chamber configured with a vertically oriented groove portion extending substantially from top to bottom of the portion of the airbag facing the occupant to be protected. The term "recess" as used herein and in the claims means a concavity on a surface, such as a setback or indented surround. In this embodiment, the main panel of the airbag has an elongated slit or opening forming the inlet, opening or mouth of the recess. Figure 1C , 1D , 1E, 8A and 11A show another embodiment utilizing a similar structure to achieve approximately the same size groove portion. The opening on the main piece is reduced in size, and a part of the main piece covers the top of the groove portion when assembled. In a broad sense, the covering portion of the main sheet provides a bridge extending across the top of the groove portion. Figure 4A illustrates the use of trapezoidal groove sections. In Figure 4B, this variation uses a portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com