Spectacle frames for shaped lenses defined by monoformal carrier surfaces

A spectacle frame and lens technology, applied in the field of glasses, can solve problems such as deviation from optical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0122] example 1( Figure 4 comparison example)

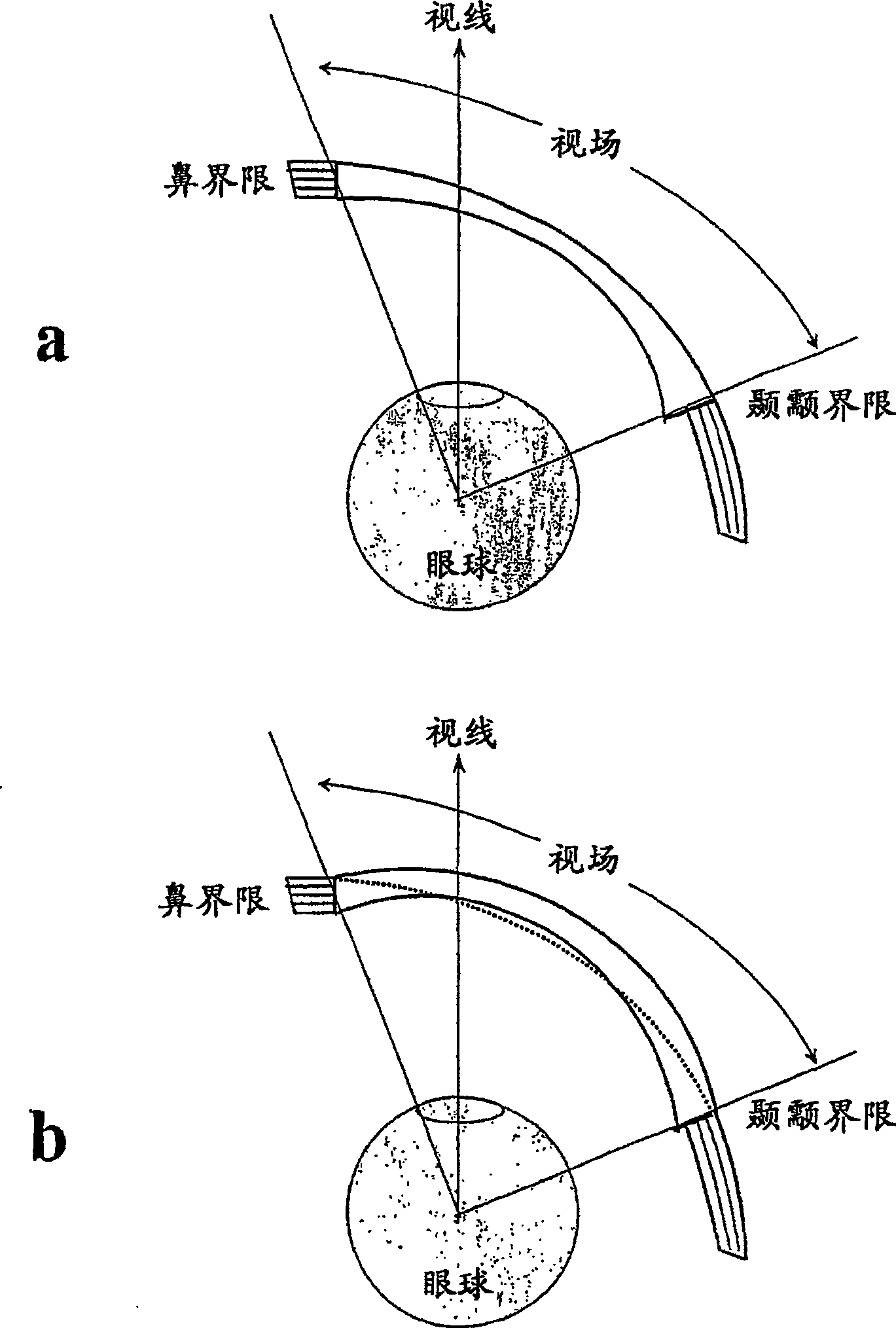

[0123] In order to study the possibility of adopting a simple geometric shape spectacle frame to clamp the lenses 3 and 4 shown in Figure 2, we express the frame bracket surface as a circular toric surface with a mathematical form similar to the sector of the lens surface,

[0124] F ( xy ) - γ = ρ 4 - ( ρ 4 - F ( x ) ) 2 - ( y - β ) 2

[0125] in

[0126] F ...

example 2

[0133] Example 2 ( Figure 5 comparison example)

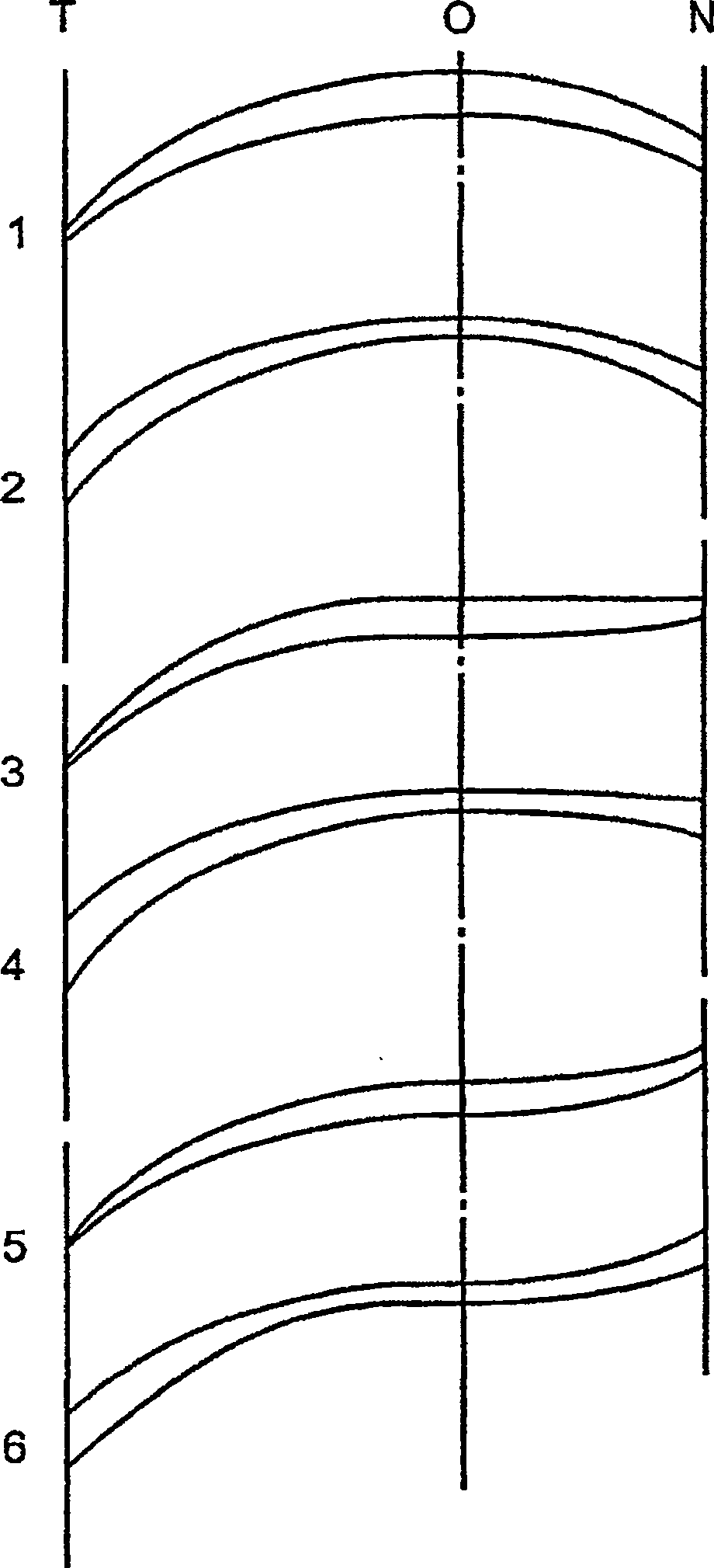

[0134] Figure 5 The solid curves shown in a and 5b represent the equatorial and prime meridian portions of the front surface of the lens, where the base curve change along the equator is in the direct line of sight of the wearer. The base curves in this example are 4.55D along the nasal region, 11.3D along the temporal region, and 7.25D perpendicular to the front apex of the lens. The surface magnifications of the polycarbonate lenses are 5D, 12.5D and 8D, respectively.

[0135] The frame aperture reference points in this example are (-21.5, 0, 2.0), (34.4, 0, 15.0), and (0, ±17.0, 2.0) relative to the lens front apex (0, 0, 0). Note that the temporal sagittal extent is 13.0 mm larger at the anterior lens periphery than in the nasal region in the horizontal direction. The mean height frame carrier face intersecting the datum point and the front apex of the lens has a horizontal curvature of 8.92D and a vertical curvature ...

example 3

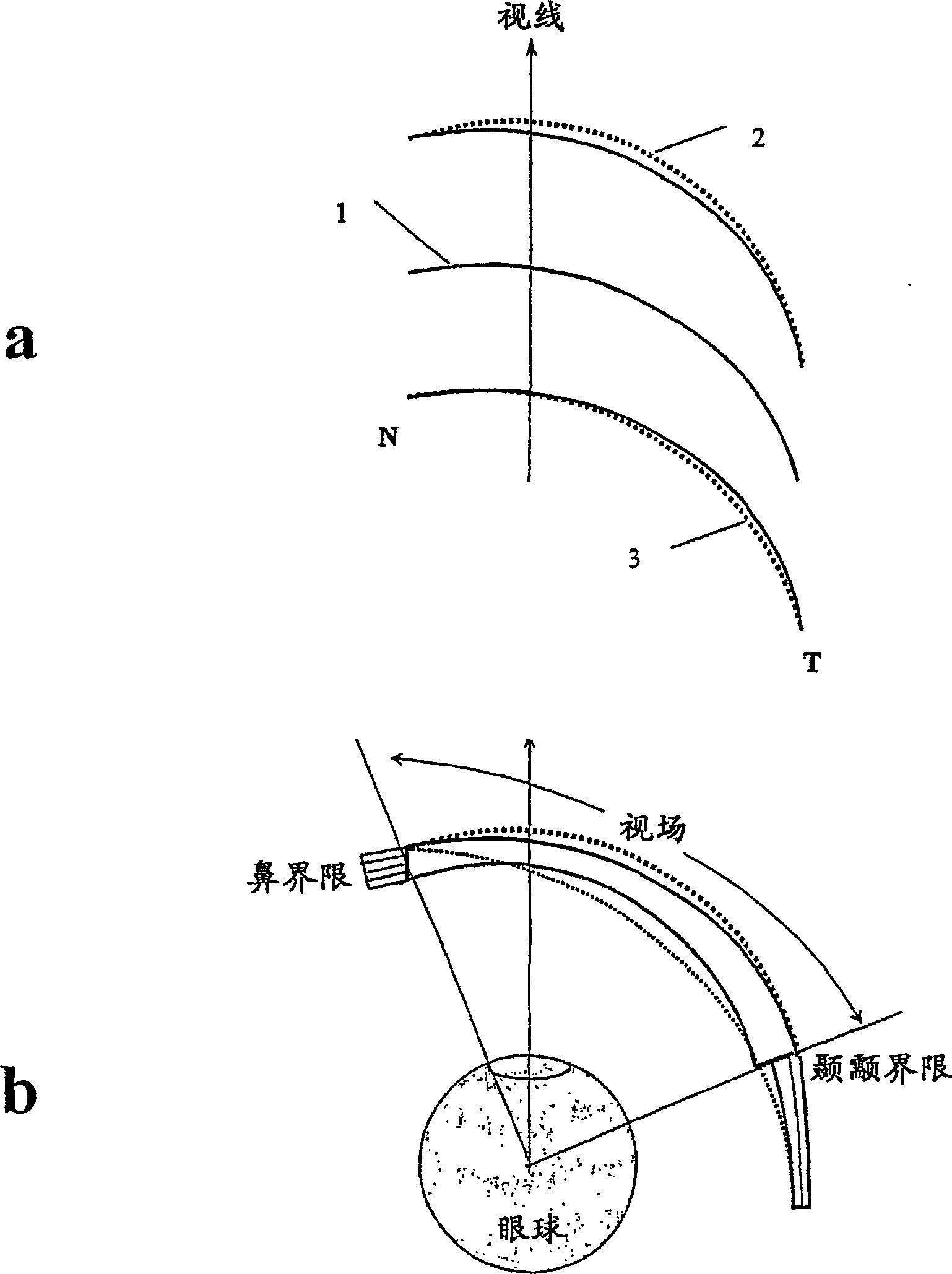

[0137] Example 3 (Figure 6)

[0138] The characteristic lens aperture shapes described in Examples 1 and 2 arise because the horizontal curvature of the marquee cradle face is close to the steepest inner boundary surface curvature on the composite lens surface. There is complete freedom in determining the shape of the lens aperture in many annular eyeglass designs if the lens surface and the rim carrier surface are congruent. Such lens frames, which emphasize changes in the base curve in the wearer's field of view towards the temporal region, have complex carrier surfaces and fit only one specific lens surface design, which is not practically ideal.

[0139] Decorative spectacles employ simple frame carrier faces of low curvature and place these faces between the front surface of the lens in the frame aperture and the wearer. As in the case shown in Example 1 and Example 2 above. In contrast, if we use a simple but highly curved frame carrier face, which is positioned in fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com