Liquid stirring machine

A mixer and liquid technology, which is applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of large occupied volume and complex structure, reduce manufacturing and assembly costs, simplify components, and package and transport. And the effect of convenient and practical installation and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

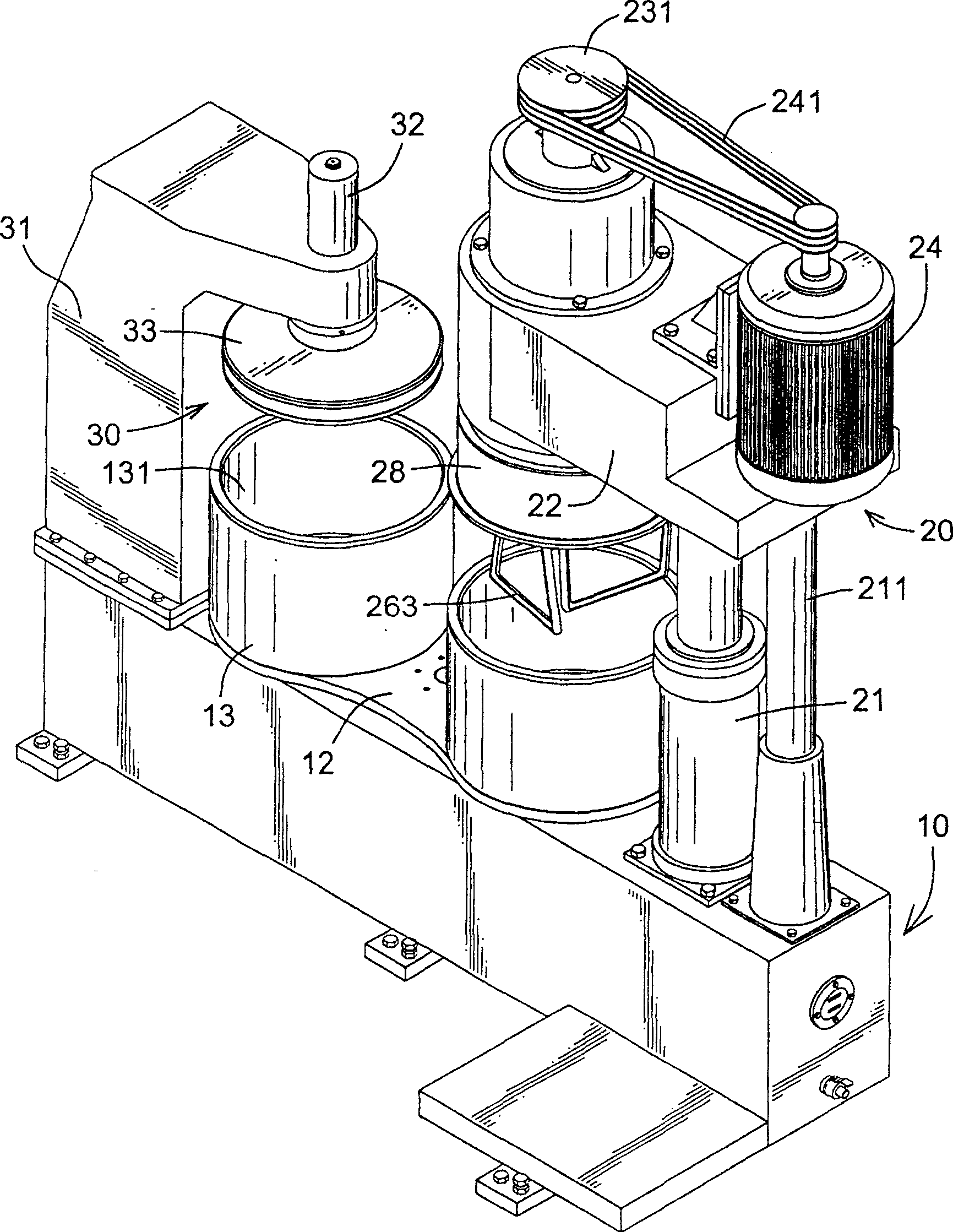

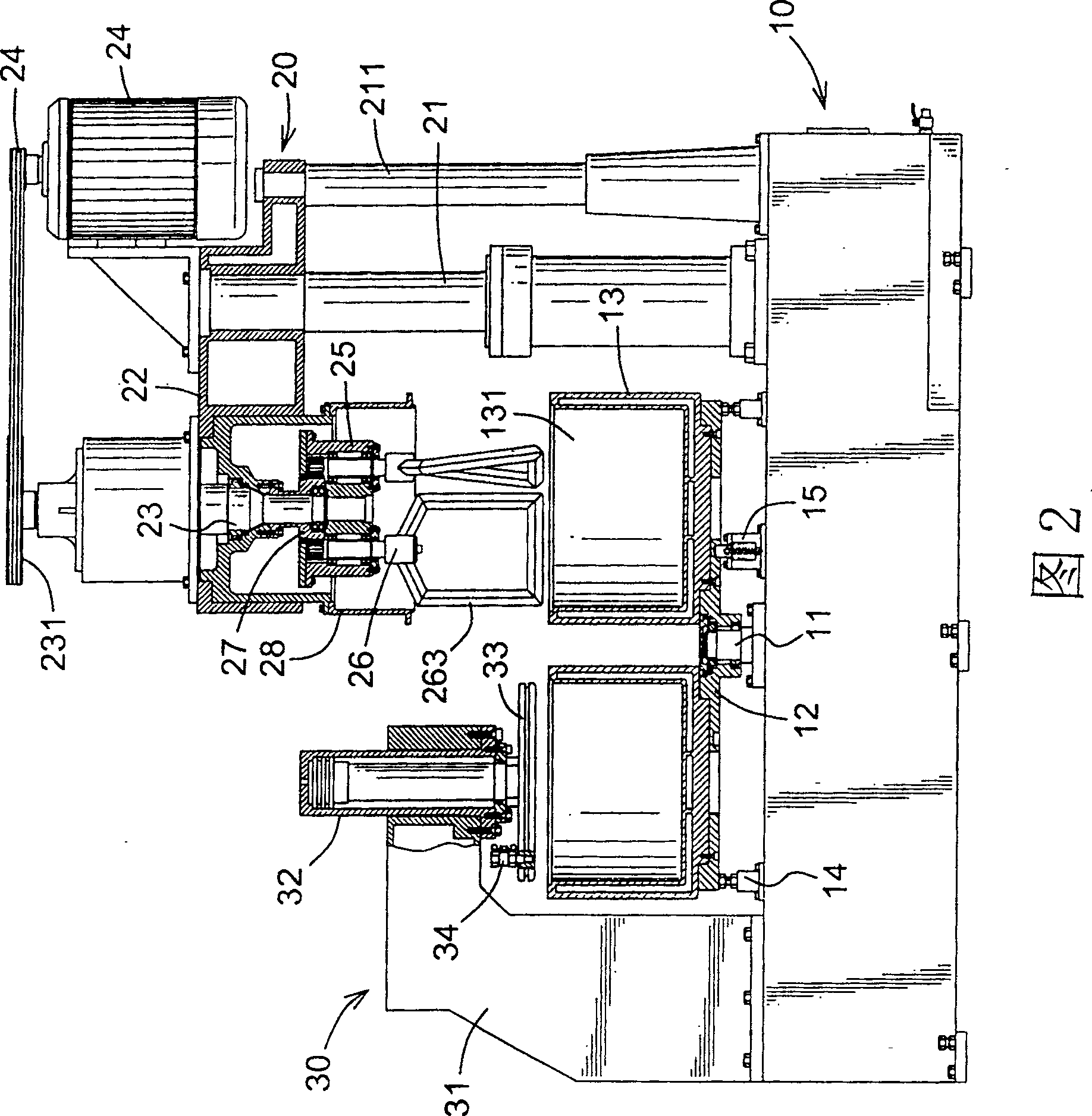

[0055] The present invention is a liquid mixer mainly used for stirring and mixing medium and high viscosity liquids, such as figure 1 , Figure 2 shows a preferred embodiment of the present invention, which is provided with a horizontally elongated base 10, and is respectively provided with a stirring device 20 and an extruding device 30 at the two ends of the base 10 in a facing pattern; in:

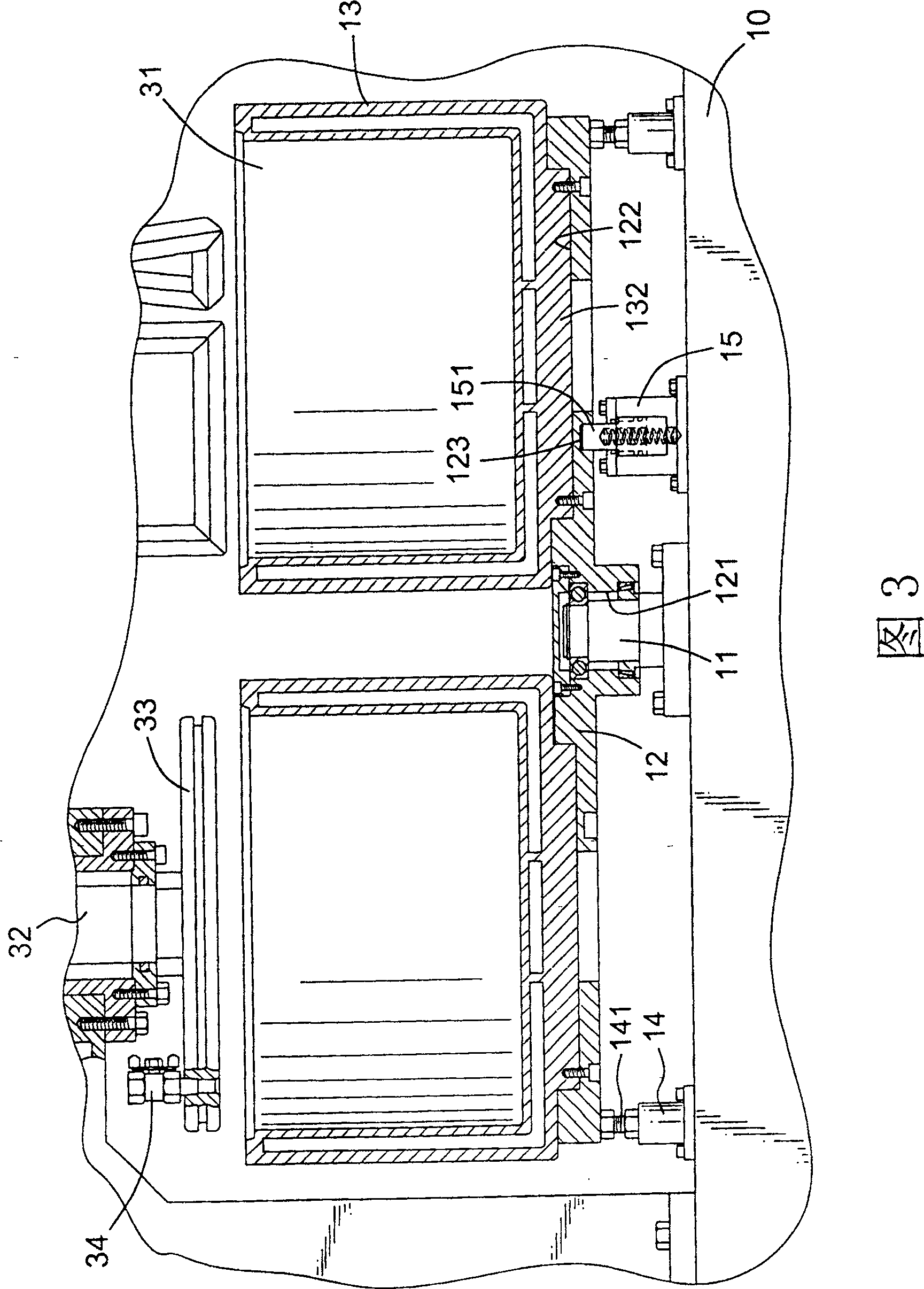

[0056] As shown in Figures 2 and 3, the base 10 is a horizontally elongated seat structure with a hollow assembly space inside for installation of hydraulic oil tanks and other related components. A shaft seat 11 is protruding from the center of the top of the base 10. Let a long rotating disk 12 be rotatably coupled to the top of the shaft seat 11. As shown in the figure, the rotating disk 12 is provided with arc edges on both ends and concave arc edges on both sides of the central part. The elongated plate, and at the bottom of the central position of the rotating disk 12 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com