Roller of swabbing floor, and mop of using the roller

A roller and mop technology, applied in application, carpet cleaning, floor cleaning, etc., can solve the problem that the floor wiper cannot adapt to push and pull back and forth, cannot be used to push back and forth, and is not easy to remove dirt, etc., to achieve ideal cleaning effect, squeezing water operation Effort-saving and convenient, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

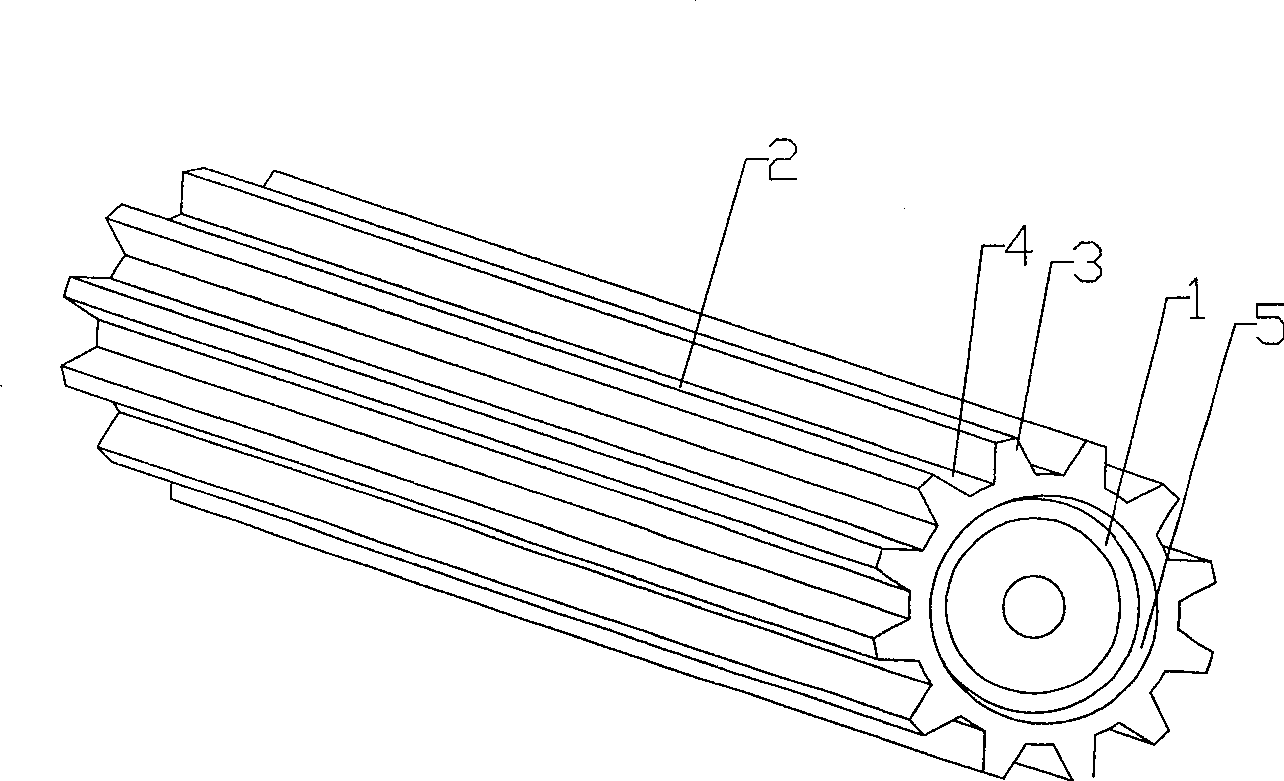

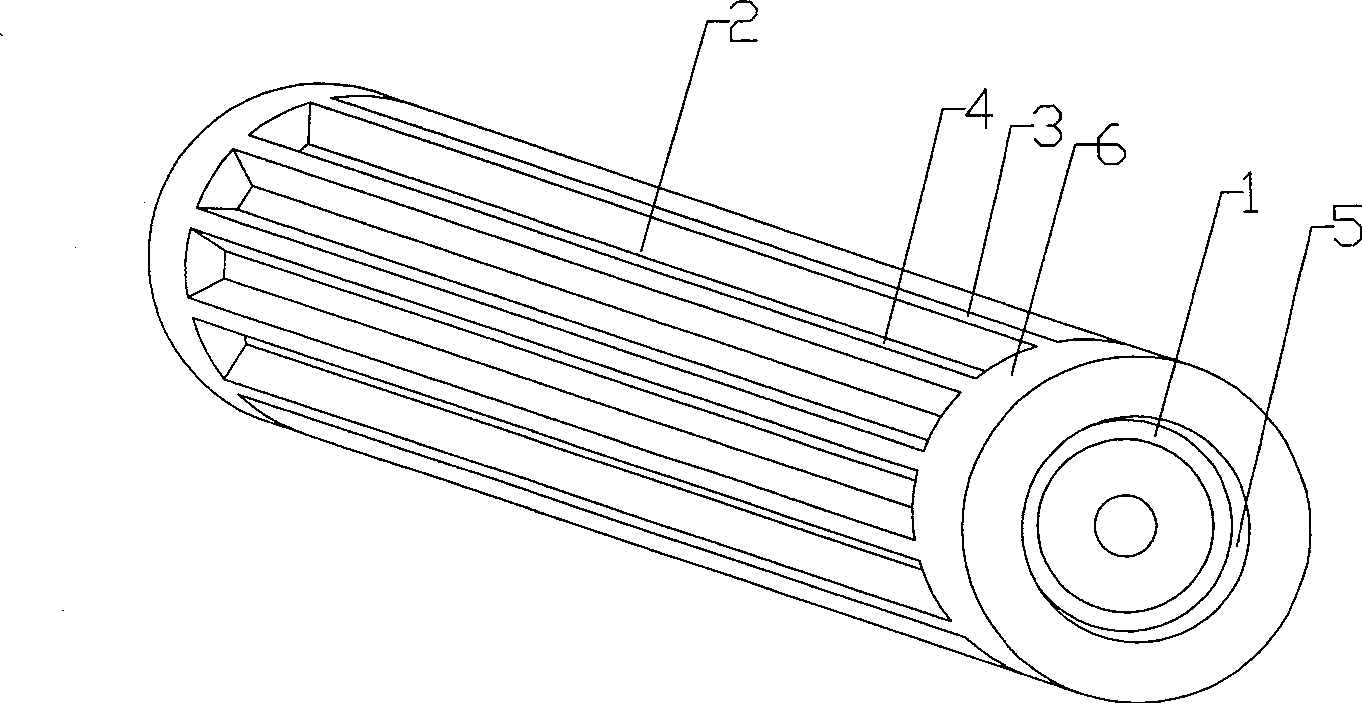

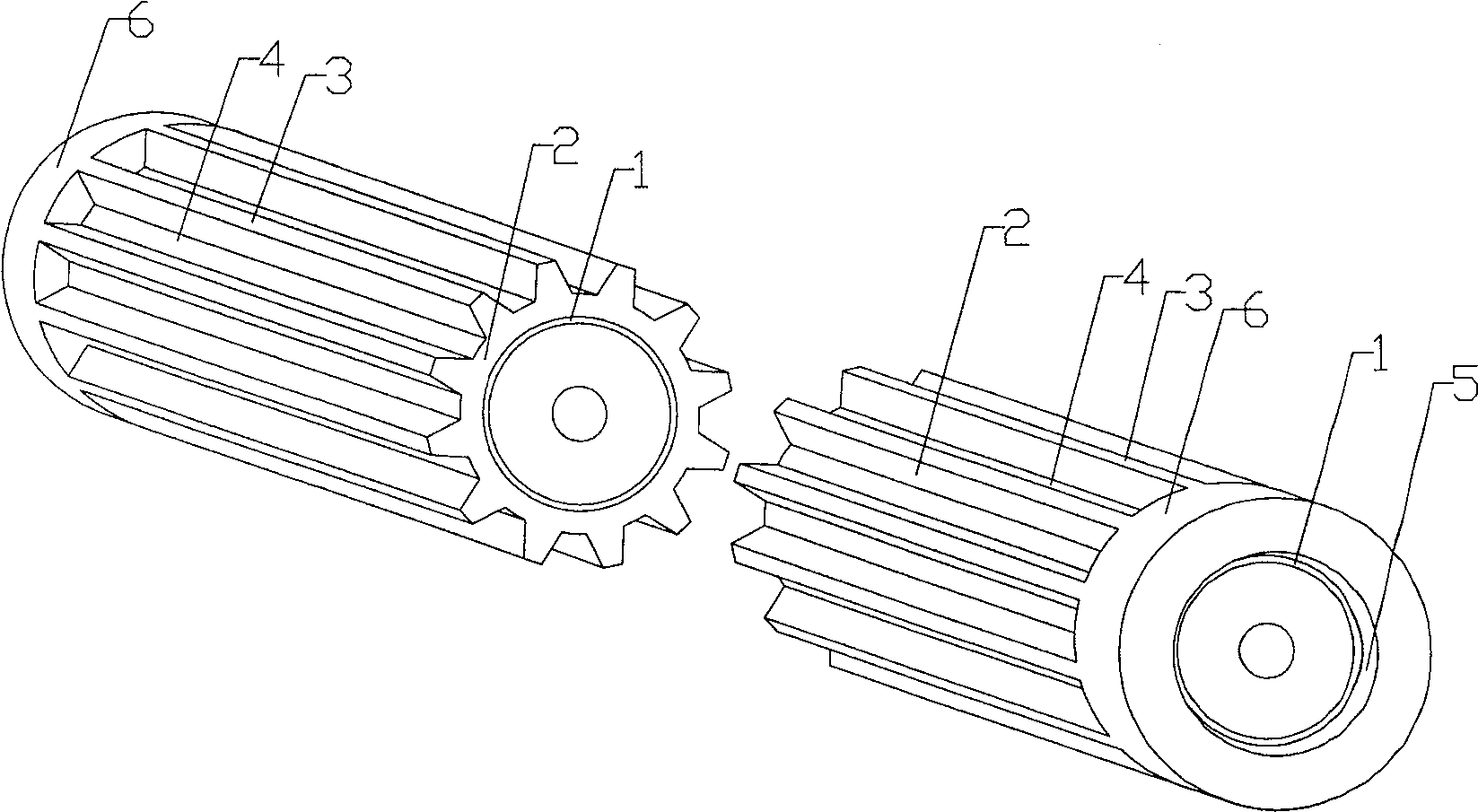

[0036] figure 1 Example 1 of the present invention is given. The roller frame 1 of the floor wiping roller of the present embodiment is provided with wipes. The wiper is the collodion 2 wrapped on the roller frame, and the outer surface of the collodion is distributed with straight ribs 3 and grooves 4 . The roller frame is made of plastic, and the collodion is sleeved on it, and the collodion is ring-shaped at the socket of the roller frame, and the collodion is bonded and connected with the roller frame. Mopping roller one end 5 collodion grows roller frame.

[0037] Because the collodion has good water absorption performance, it is beneficial to dry the sewage on the ground. The dirt adsorbed on the outer surface of the collodion is also easy to be removed; it is very convenient to clean the mopping roller. It is worth mentioning that: pour a glass of water onto the collodion of the mopping roller, press down and rotate the mopping roller, and the cleaning of the moppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com