Inductive device

A technology of induction device and assembly part, applied in the direction of electrical components, electric switches, circuits, etc., can solve problems such as affecting the use quality, dust adhesion, affecting the conduction effect of ball switches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The sensing device according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0030] Before the present invention is described in detail, it should be noted that the relative position terms used in the following descriptions, such as "horizontal direction X" and "vertical direction Y", are based on the directions shown in each figure, and are similar to Components are denoted by the same number.

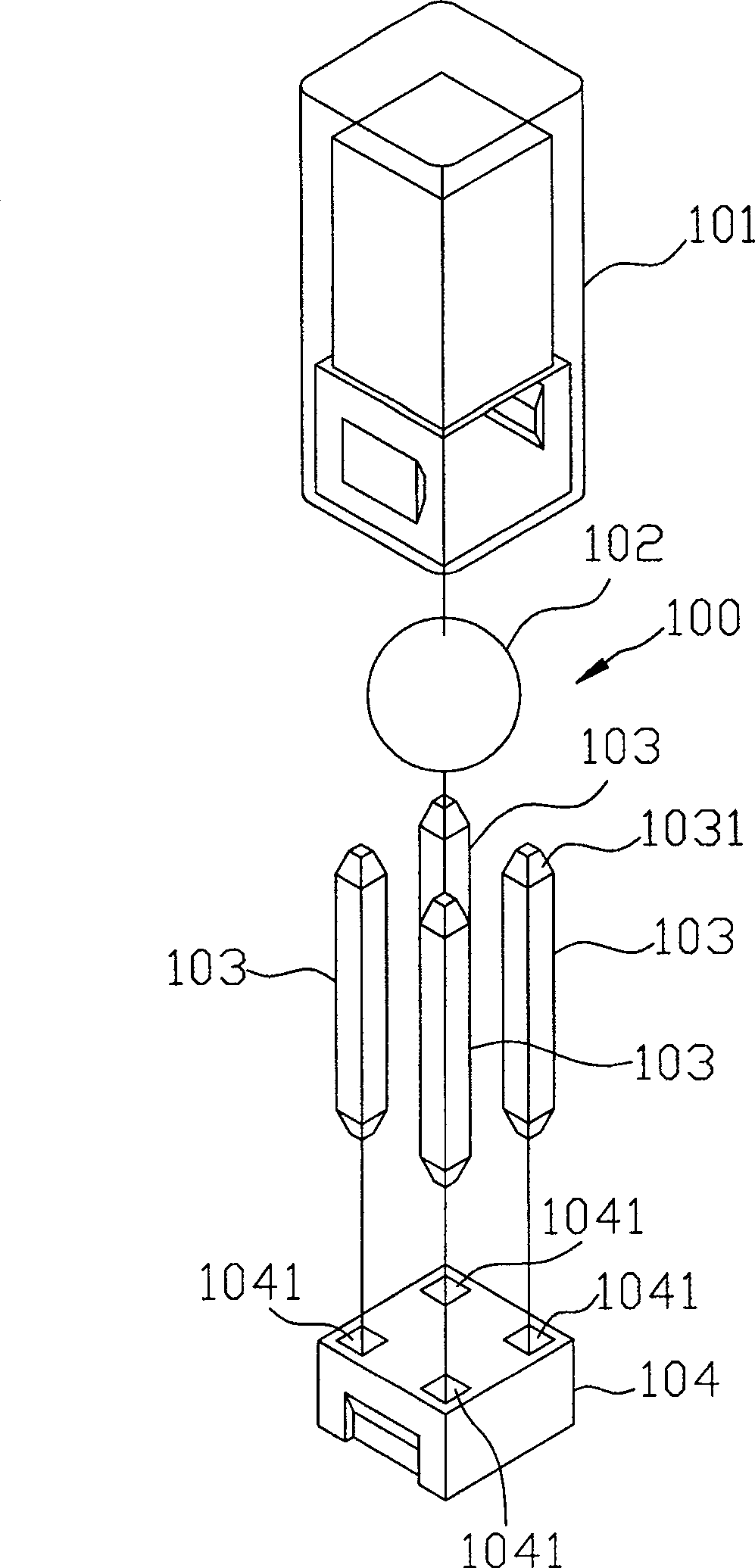

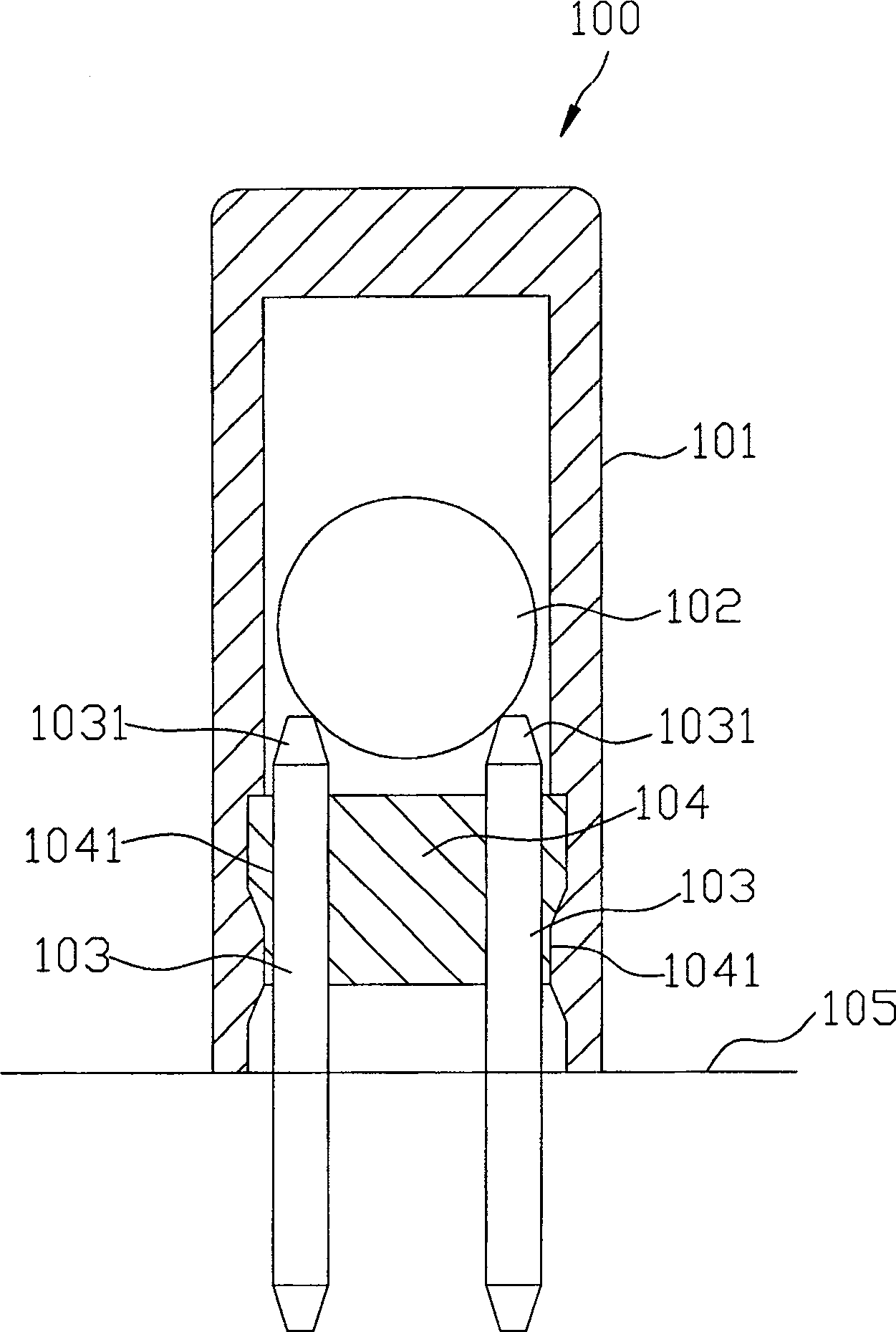

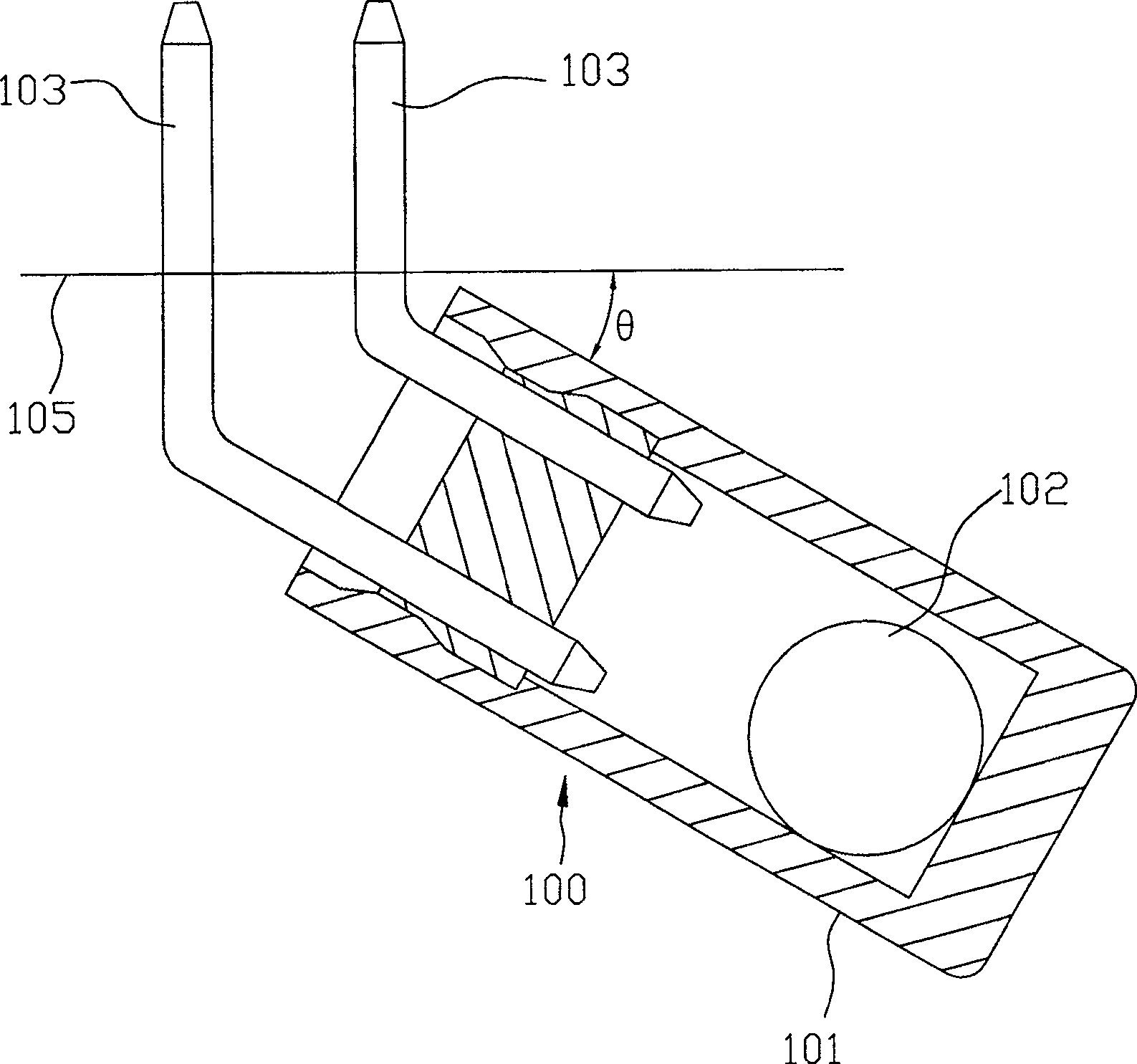

[0031] refer to Figure 4 , Figure 5 , Image 6 , A first preferred embodiment of the sensing device of the present invention includes a hollow seat body 1 , two terminal units 200 , and a ball 4 .

[0032] The hollow seat body 1 is made of insulating material, including a first side 11 and a second side 12 in opposite directions, a receiving hole 13 communicating with the first side 11 and the second side 12, and a plurality of The assembly portion 14 respectively extends outward from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com