Straw returning machine suitable for working in the field with many kinds of row spacing

A technology of straw and row spacing, which is applied to crop processing machines, agricultural machinery and tools, and agriculture, and can solve the problems of poor agronomic adaptability of straw returning machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

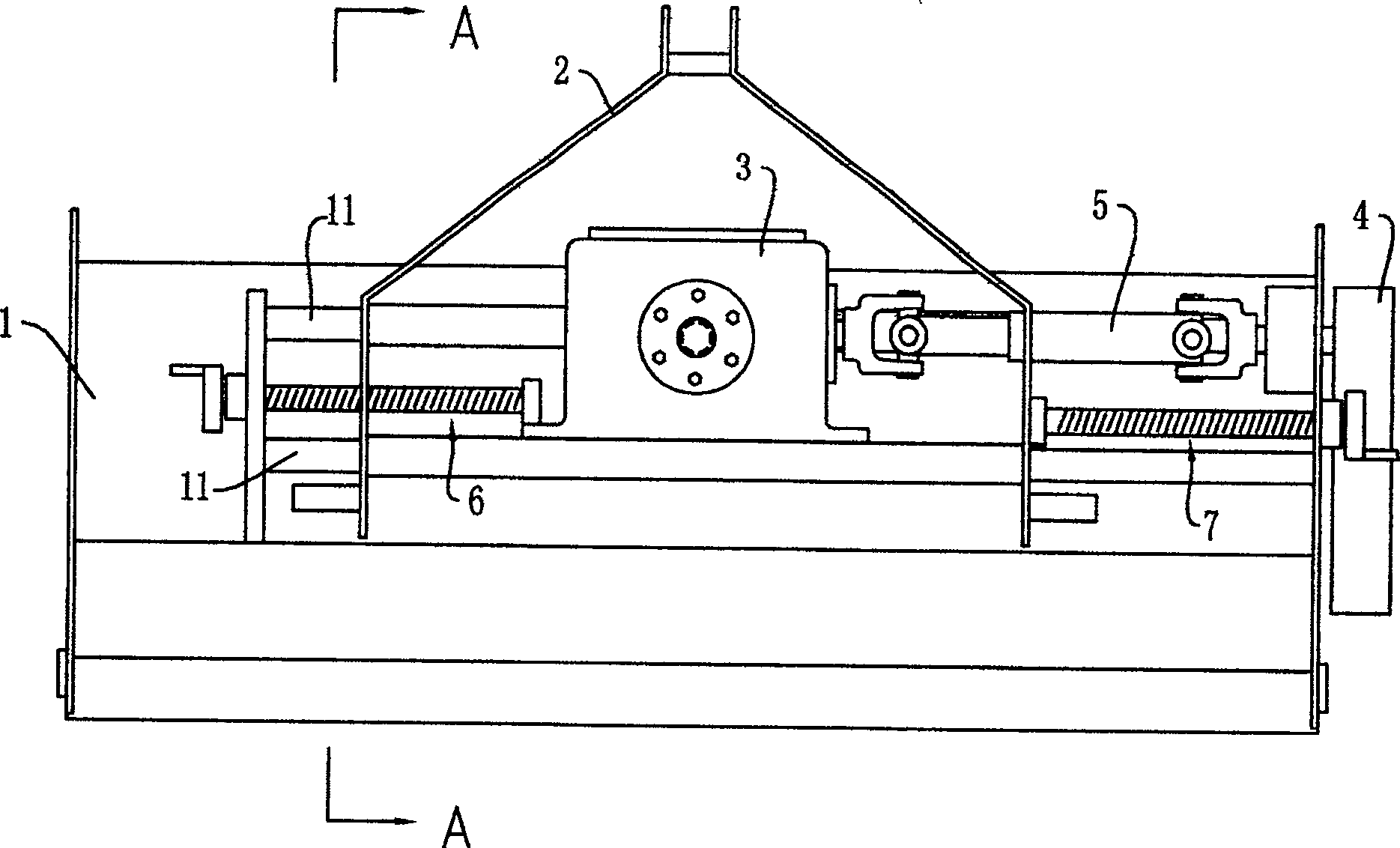

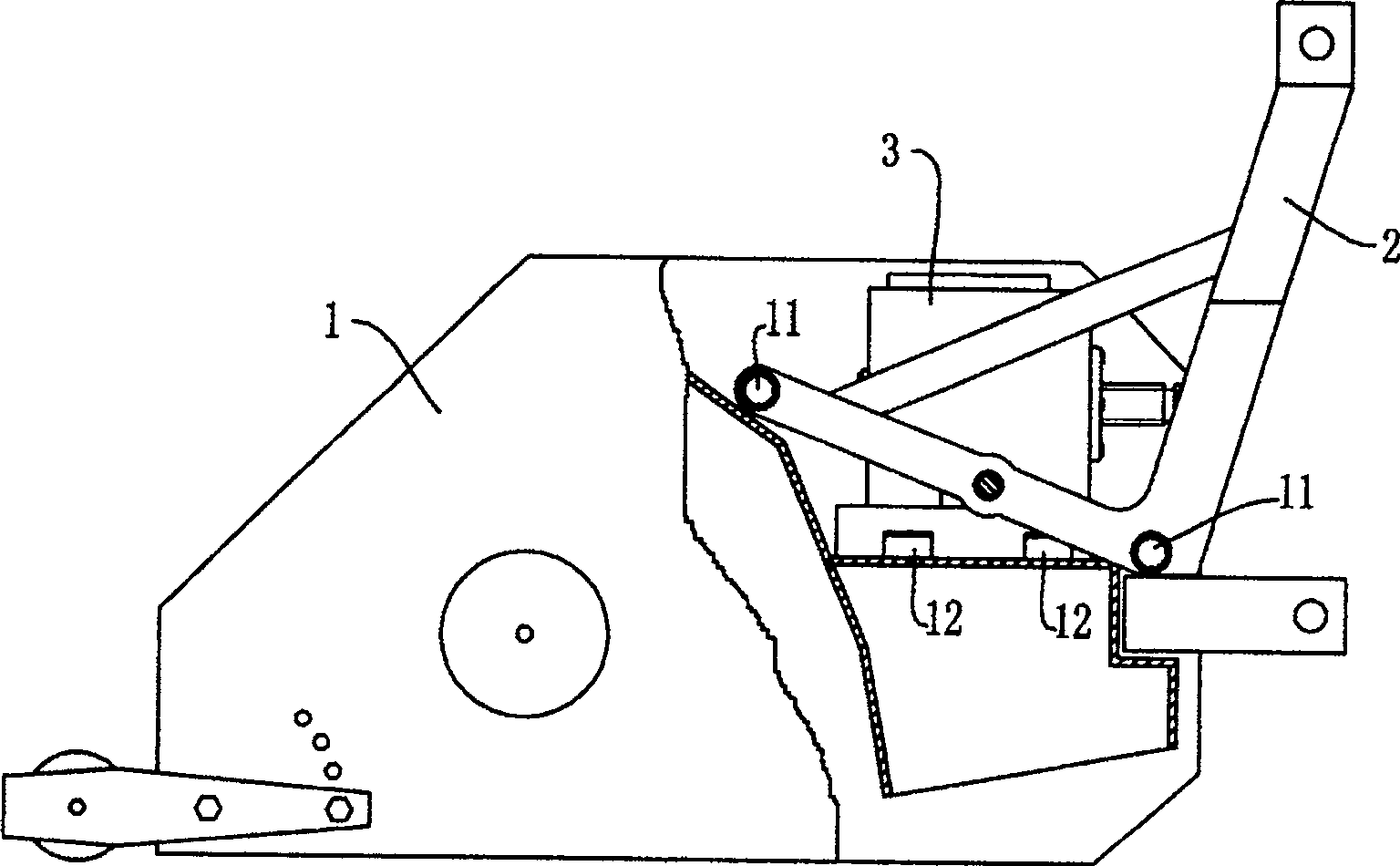

[0009] A straw returning machine suitable for various row spacing operations, such as figure 1 As shown, the frame 1 is fixed longitudinally with two support beams 11, the traction frame 2 is sleeved on the support beams 11, and a first adjustment device 7 is provided between the frame 1 and the traction frame 2, Described first adjustment device 7 is made of lead screw nut adjustment device, when rotating the hand wheel that is fixed on screw mandrel like this, can make traction frame 2 move along support beam 11, thereby can adjust the relative position of traction frame and frame, and then Adjust the relative position of the tractor and the straw returning machine, so it can be properly adjusted according to the different row spacing of the crops under different planting agronomic conditions, which not only ensures the field passability of the tractor, but also ensures that the straw returning machine will not cross the field ridge , thus enhancing the agronomic adaptabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com