Two-material atomizing device

An atomization device and dual-material technology, which can be used in spraying devices, liquid spraying devices, lighting and heating equipment, etc., can solve the problem that the nozzle is not suitable for atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

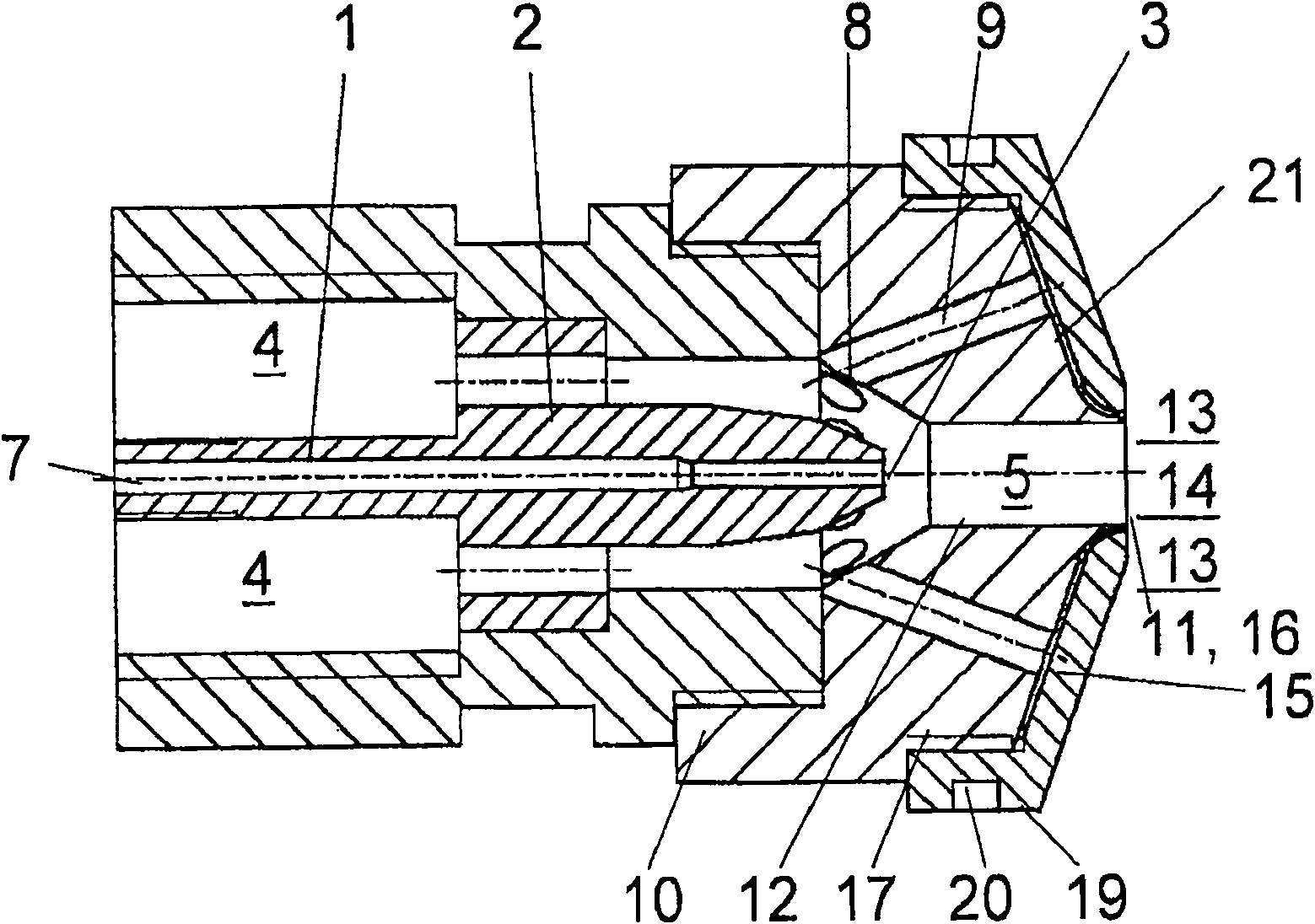

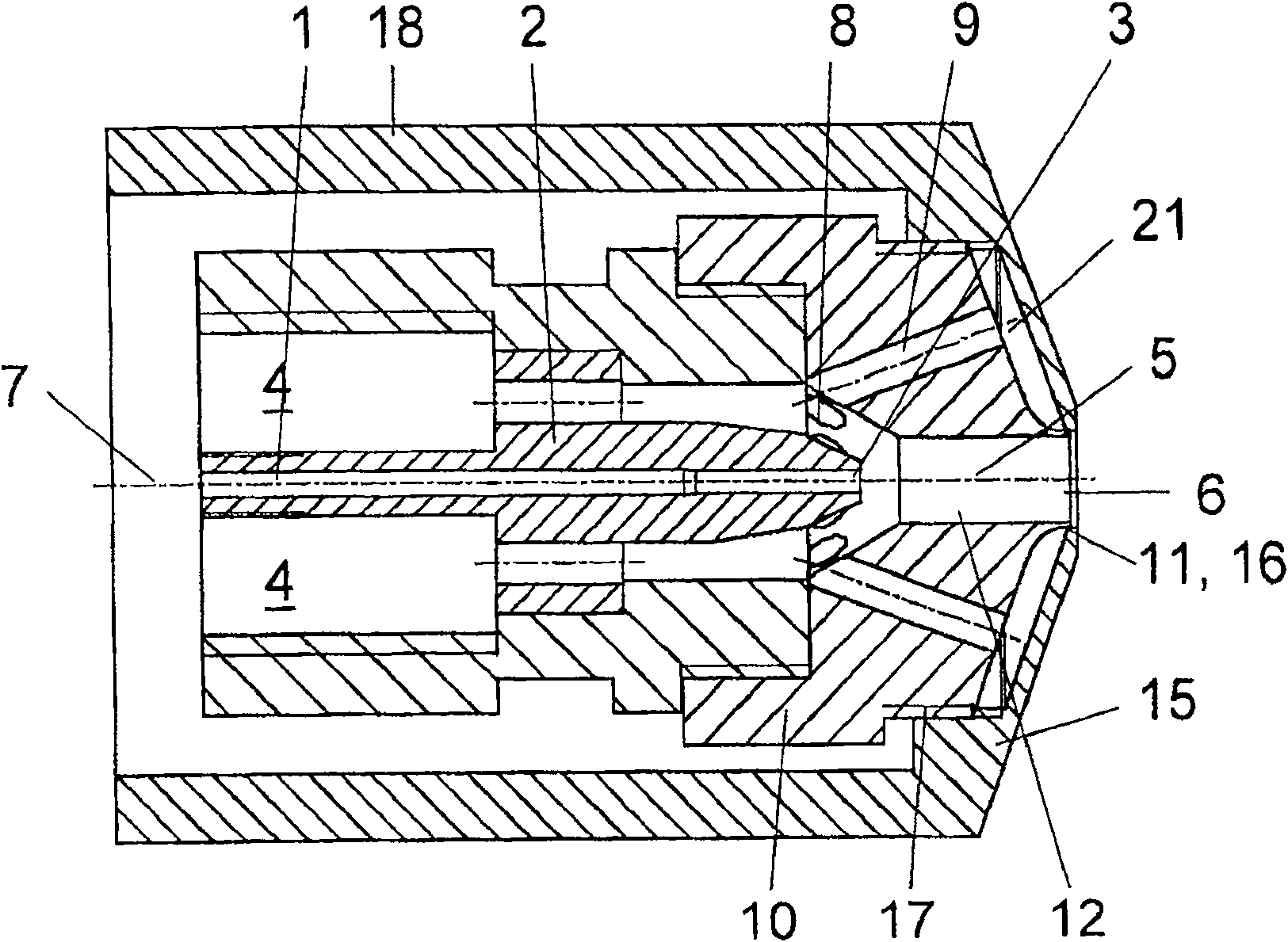

[0021] Both embodiments of the two-material atomizing device comprise a liquid delivery channel 1 arranged in a preferably tubular liquid delivery housing 2 with a nozzle opening 3 (on the end side) and surrounding the liquid delivery channel or The gas delivery channel 4 is concentrically arranged in the liquid delivery housing, wherein the nozzle openings terminate in the gas delivery channel. In the continuation of this material confluence channel downstream (at the end) is connected a mixing channel 5 , in which the aforementioned materials (gas and liquid) mix and leave again via the outflow opening 6 (on the end side) . The liquid delivery channel 1 , the gas delivery channel 4 , the mixing channel 5 and the outflow opening 6 are preferably rotationally symmetrical about a line of symmetry 7 . In addition, a gas branch 8 arranged concentrically with respect to the aforementioned components is provided, which branches off from the gas delivery channel 4 before the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com