Vehicle main reducing gear pre-tighten device and pre-tighten method

A main reducer and automobile technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of excessive preload of the main reducer bearing, cannot be predicted, and cannot be known, so as to ensure assembly accuracy, The effect of improving product qualification rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

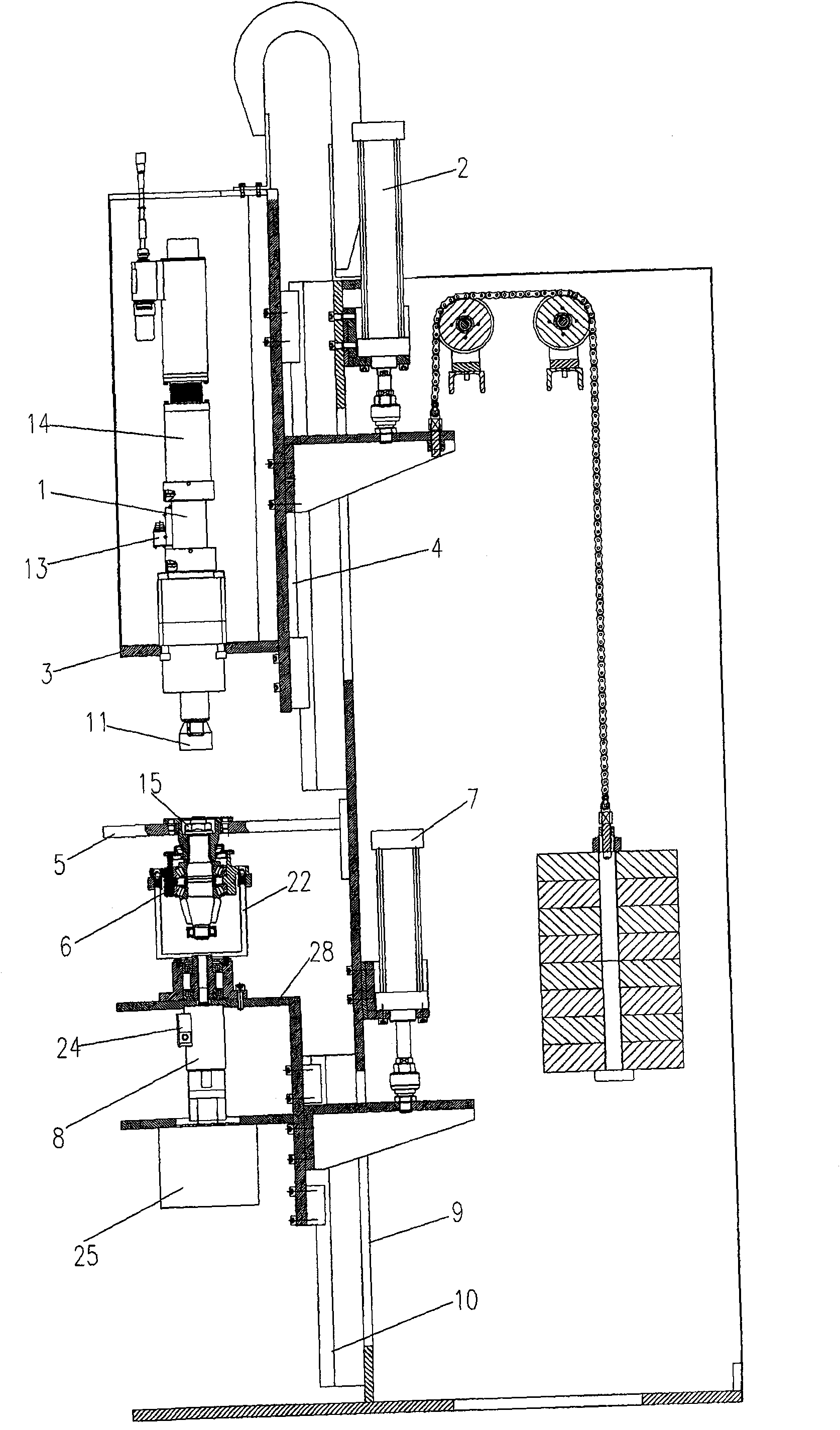

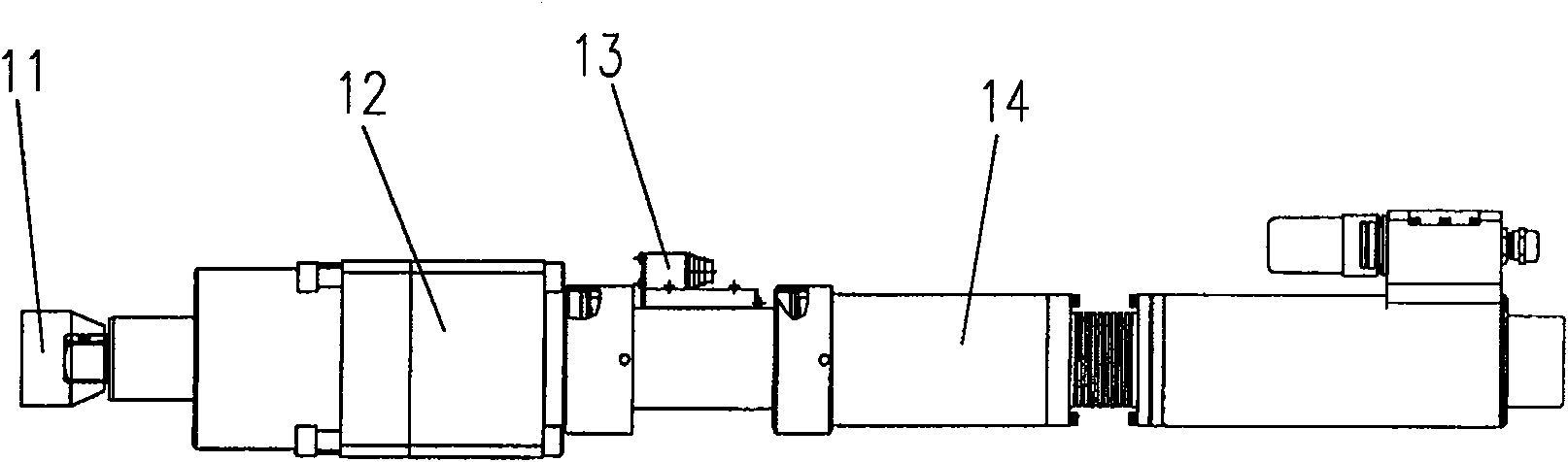

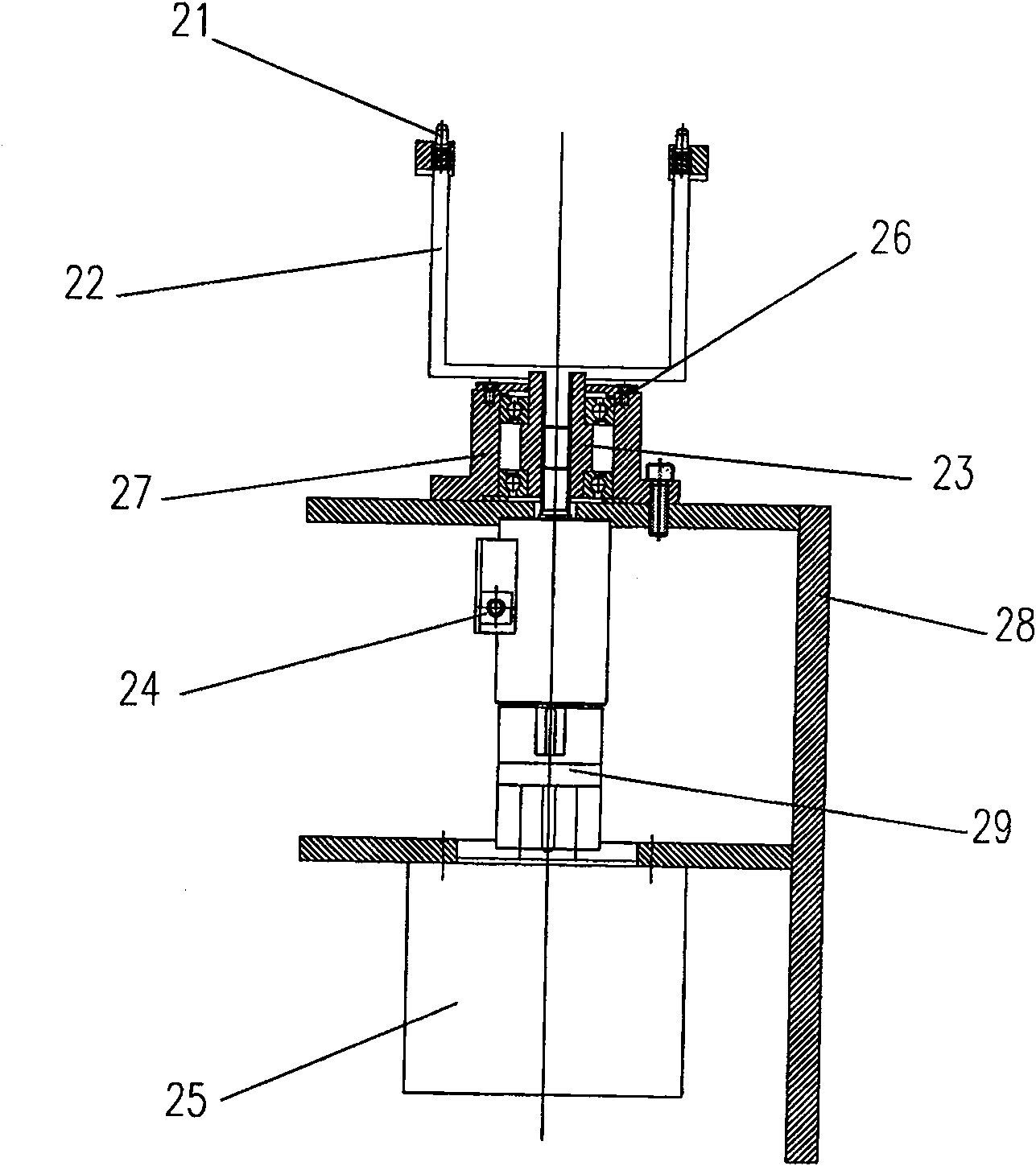

[0022] see figure 1 , set the working platform 5 for suspending the main reducer 6, on the coaxial position of the main reducer 6, above the working platform 5, set the rotatable nut tightening mechanism 1, the bottom of the nut tightening mechanism 1 The end is set as a sleeve 11 that can be firmly sleeved on the main tooth nut 15 and linked with the rotating shaft of the nut tightening mechanism 1, and the main tooth nut tightening torque sensor 13 is arranged in the rotating shaft of the nut tightening mechanism 1; it is located on the working platform 5 Below, a rotatable bearing pretightening torque measuring mechanism 8 is set. The bearing pretightening torque measuring mechanism 8 has a pair of symmetrical holes that can be inserted into the bearing seat 18 of the final drive and is linked with the rotating shaft of the bearing pretightening torque measuring mechanism 8. The measuring claw 22 is provided with a main tooth bearing preload torque sensor 24 in the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com