SiCO-Li composite, making method, and non-aqueous electrolyte secondary cell negative electrode material

A technology of composite materials and mixtures, applied in the direction of battery electrodes, negative electrodes, active material electrodes, etc., can solve the problems of inability to form carbon coating, insufficient conductivity, insufficient use of secondary batteries, etc., and achieve satisfactory cycle performance and unique discharge Features, Effects of Satisfactory Initial Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

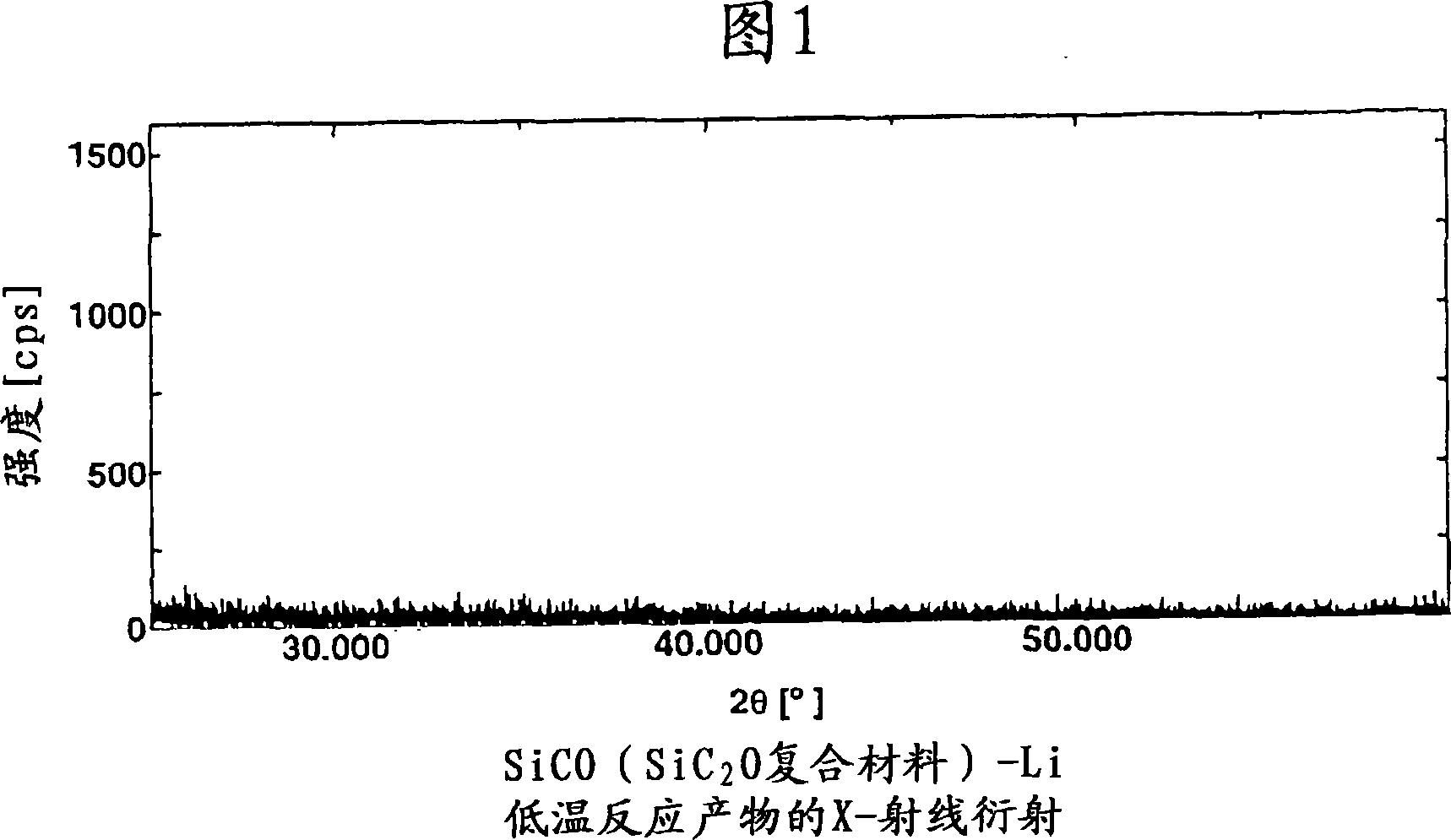

Embodiment 1

[0112] To 120 g of tetramethyltetravinylcyclotetrasiloxane (LS-8670, Shin-Etsu Chemical Co., Ltd.) and 80 g of methylhydrogensiloxane (KF-99, Shin-Etsu Chemical Co., Ltd.) To the curable silicone mixture was added 0.1 g of chloroplatinic acid catalyst (1% solution in chloroplatinic acid). The mixture was mixed thoroughly and pre-cured at 60°C for 1 day. The pre-cured mixture in the form of pellets was placed in a glass container and further placed in an atmosphere-controlled, temperature-programmed muffle furnace where the pre-cured mixture was heated at 200 °C for 2 hours in a nitrogen atmosphere until it is fully cured. The solidified product was pulverized and ground to an average particle size of 10 micrometers in a ball mill using hexane as a dispersion medium. Then the powder was placed in a capped alumina container, and fired at 1000° C. for 3 hours in a nitrogen atmosphere in a muffle furnace with controlled atmosphere and temperature program. After cooling, the cal...

Embodiment 2

[0121] Siloxane powder X-52-1621 (Shin-Etsu Chemical Co., Ltd.) (it has the general formula: (CH 3 SiO 3 / 2 ) n A spherical, trifunctional, highly cross-linked methylsiloxane polymer with an average particle size of about 10 microns) was placed in a covered alumina container. The container was placed in an atmosphere-controlled, temperature-programmed muffle furnace, where the powder was calcined at 1000° C. for 3 hours in a nitrogen atmosphere. After cooling, the calcined product was pulverized on a masscolloider with a clearance of 20 microns to obtain Si-C-O composite powder with an average particle size of about 10 microns.

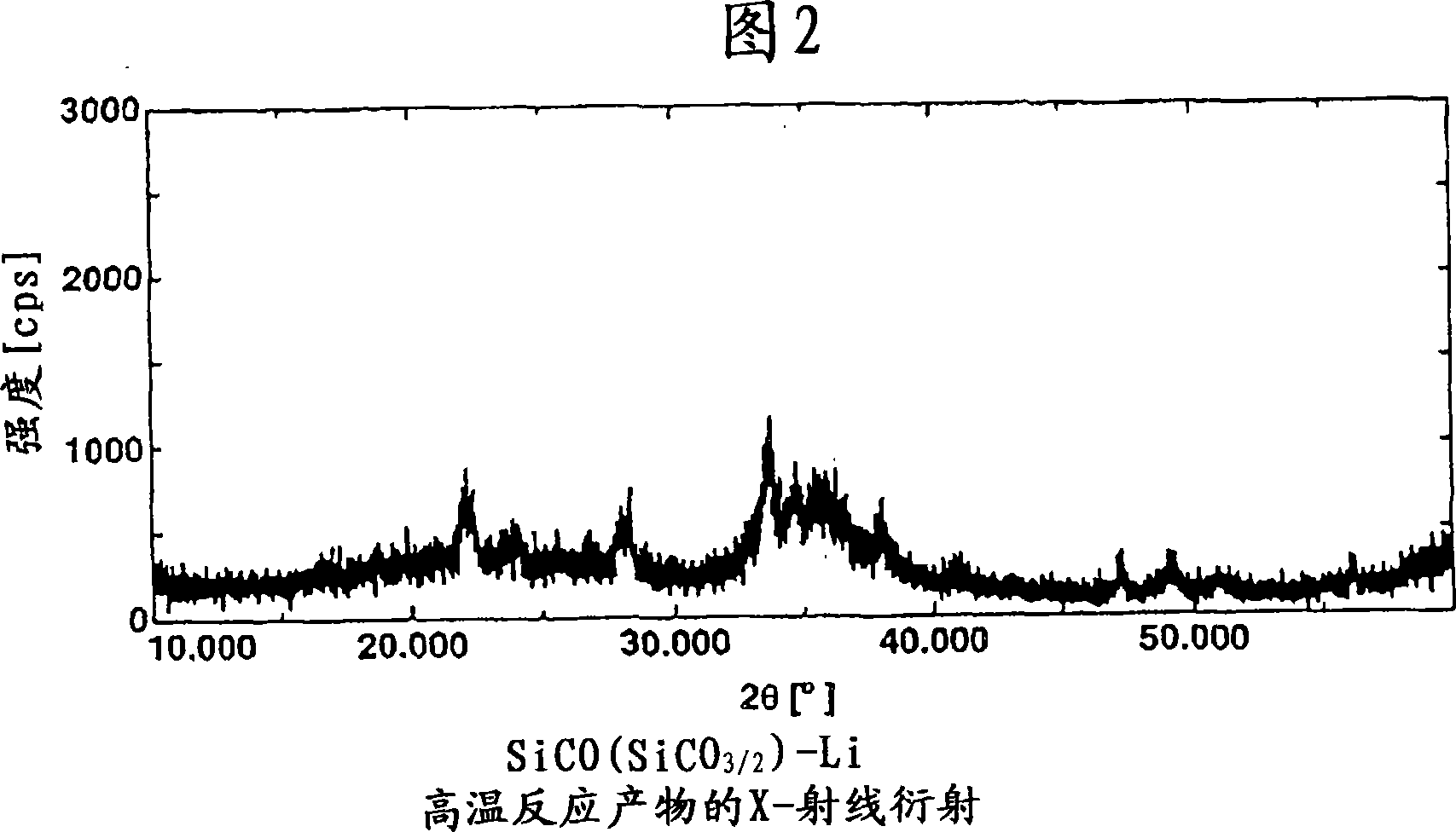

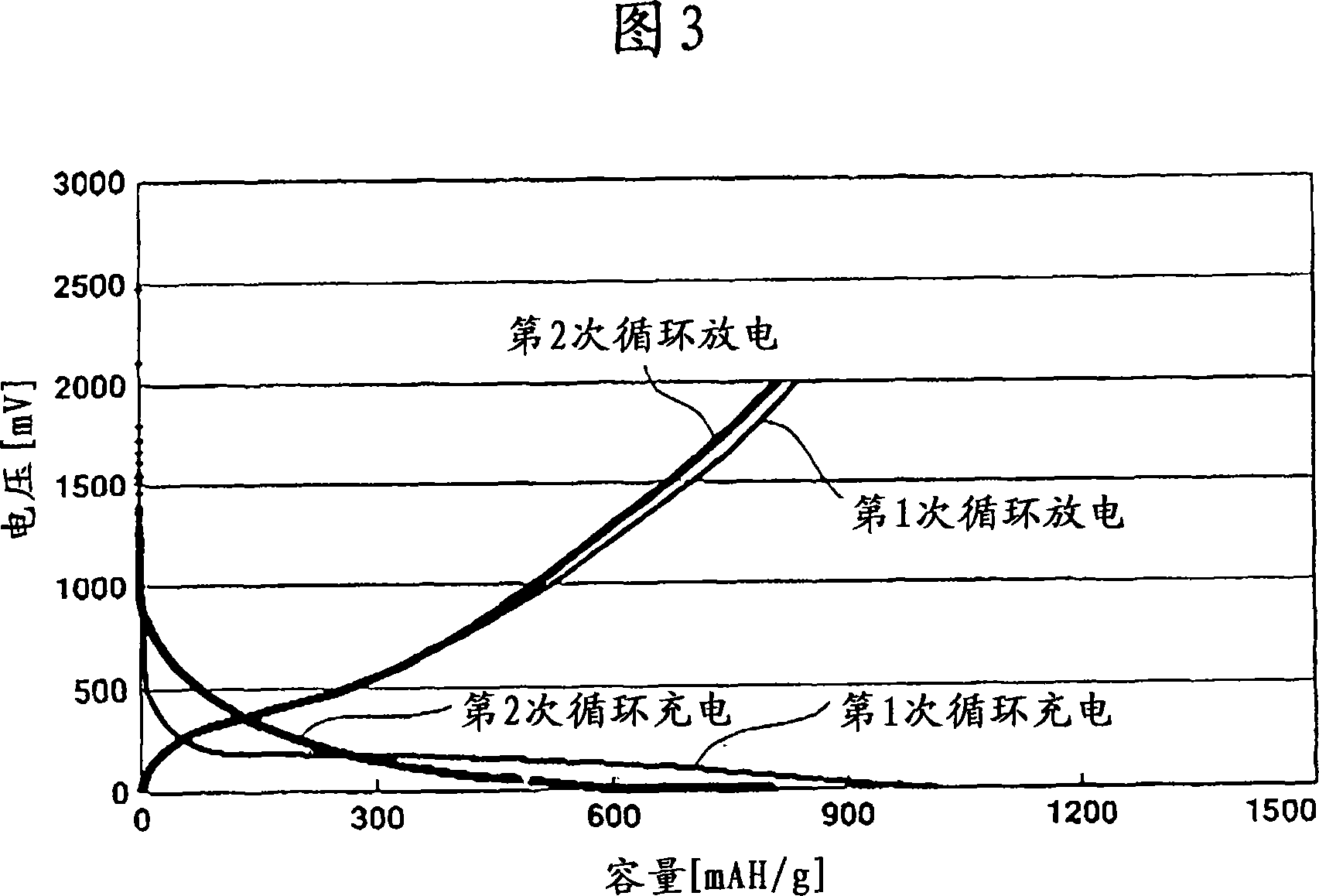

[0122] In a glove box, under an argon blanket, a portion (17.0 g) of the Si-C-O composite powder was weighed and placed into a glass vial with an internal volume of about 50 ml. To this vial was added 3.0 g of stabilized lithium powder SLMP (FMC Corp.), closed with the cap and shaken manually for mixing. The mixture was transferred to a 500 ml stai...

Embodiment 3

[0126] 120 g of tetramethyltetravinylcyclotetrasiloxane (LS-8670, Shin-Etsu Chemical Co., Ltd.), 80 g of methylhydrogensiloxane, were added to 50 g of naturally occurring flake graphite with an average particle size of 6 μm. (KF-99, Shin-Etsu Chemical Co., Ltd.) and 0.5 g of chloroplatinic acid catalyst (1% chloroplatinic acid solution) in a curable silicone mixture. A further 100 ml of hexane was added. The mixture in patty form was mixed thoroughly and then heated at 60°C to remove solvent and pre-cure. The mixture was cured at 200°C for 1 hour in air.

[0127] The solidified mixture in the form of agglomerates was pulverized and then ground to an average particle size of 15 micrometers in a ball mill using hexane as a dispersion medium. After removing the solvent, the powder was placed in a covered alumina container and calcined at 1000° C. for 3 hours in an atmosphere-controlled, temperature-programmed muffle furnace in a nitrogen atmosphere. After cooling, the calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com