Manufacturing method of liqiud crystal display device

一种液晶显示装置、液体组合物的技术,应用在非线性光学、仪器、光学等方向,能够解决制造工艺耗费较长时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

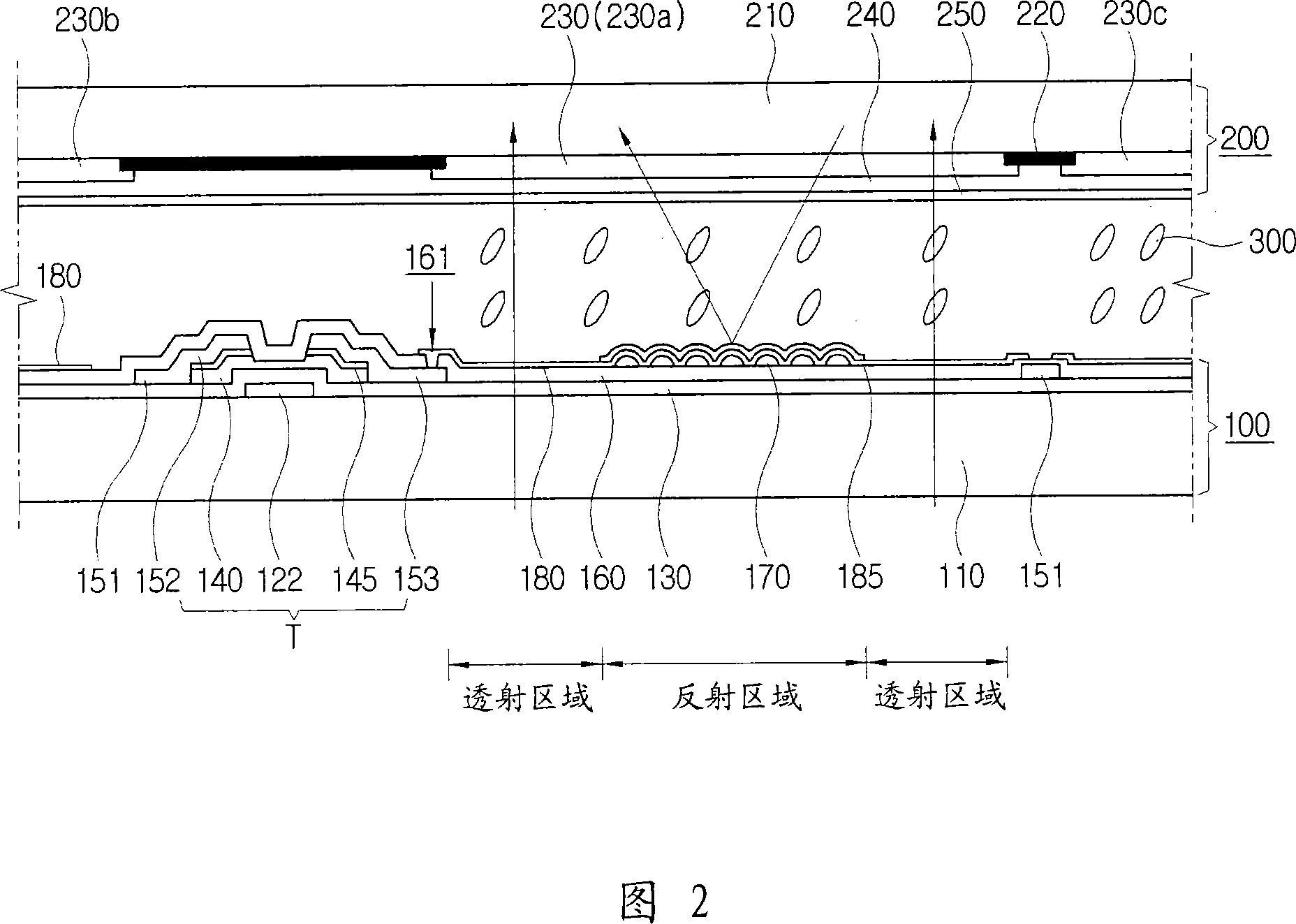

[0039] Reference is now made in detail to the embodiments of the present invention, examples of which are shown in the accompanying drawings, in which like reference numerals always indicate similar elements. The embodiments are described below to explain the present invention by referring to the figures.

[0040] Hereinafter, a transflective liquid crystal display device is representatively described, but the present invention is not limited to this, but can be applied to a reflective liquid crystal display device.

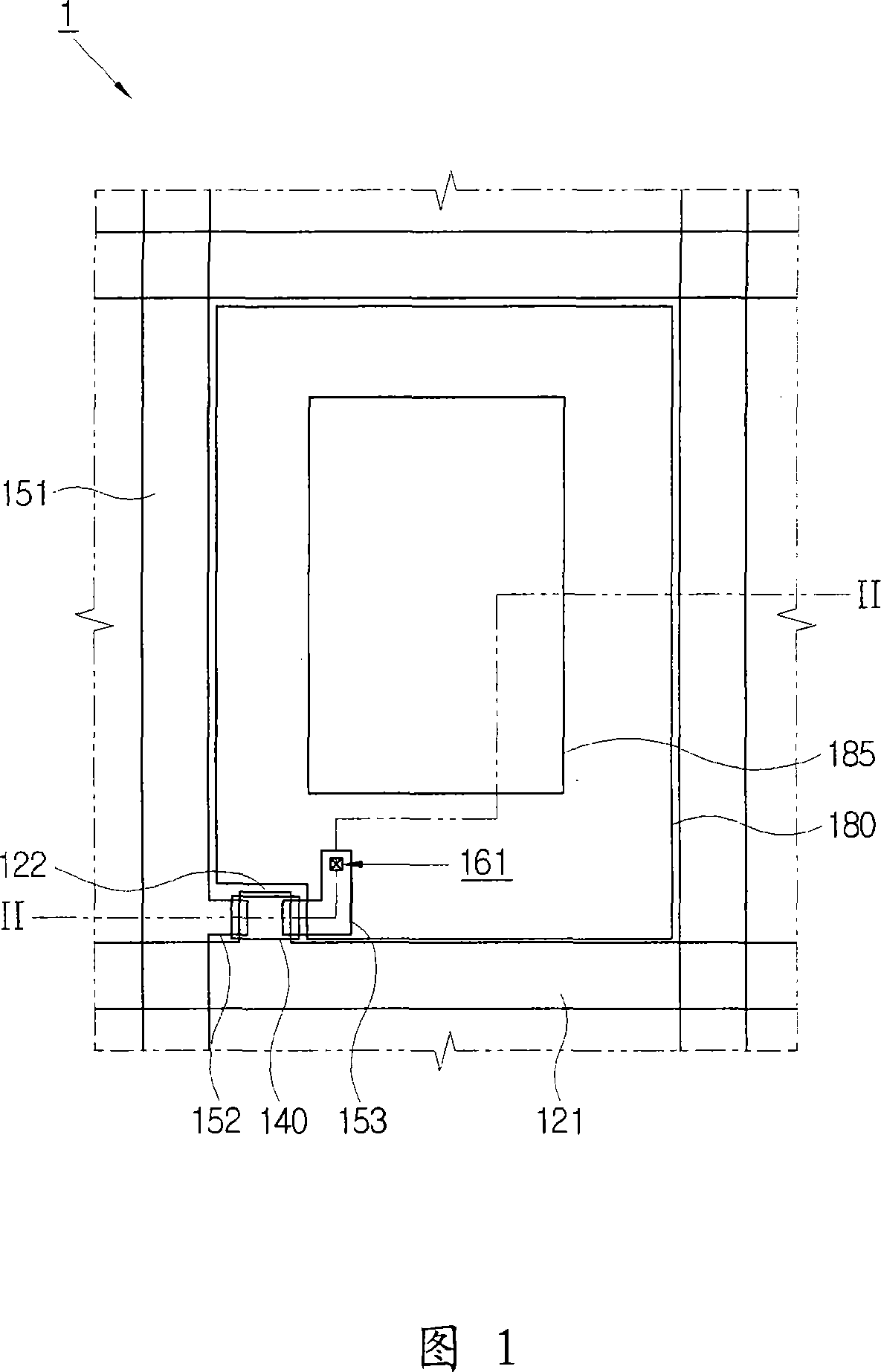

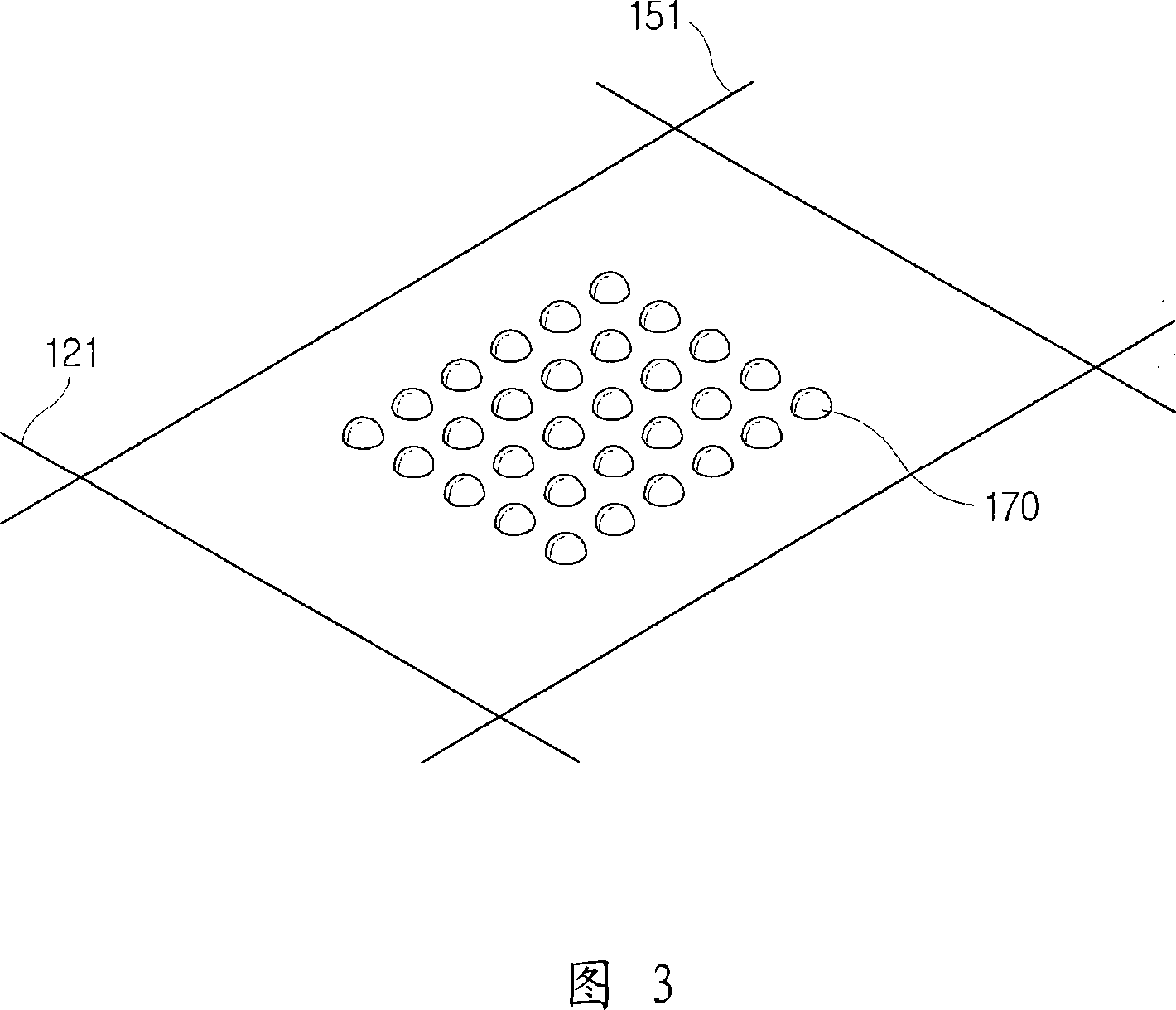

[0041] As shown in FIGS. 1 to 3, the liquid crystal display device manufactured by the manufacturing method according to the first embodiment of the present invention includes a lower substrate 100, an upper substrate 200 facing the lower substrate 100, and a liquid crystal layer 300 interposed therebetween.

[0042] In the lower substrate 100, the gate line 121 is formed on the first insulating substrate 110. The gate line 121 extends horizontally (as shown in FIG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com