Continuous paper cutting apparatus

A technology for cutting equipment and paper, applied in the direction of sending objects, metal processing, thin material processing, etc., can solve the problem of not being able to control the position of the paper cutter and the position of continuous paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

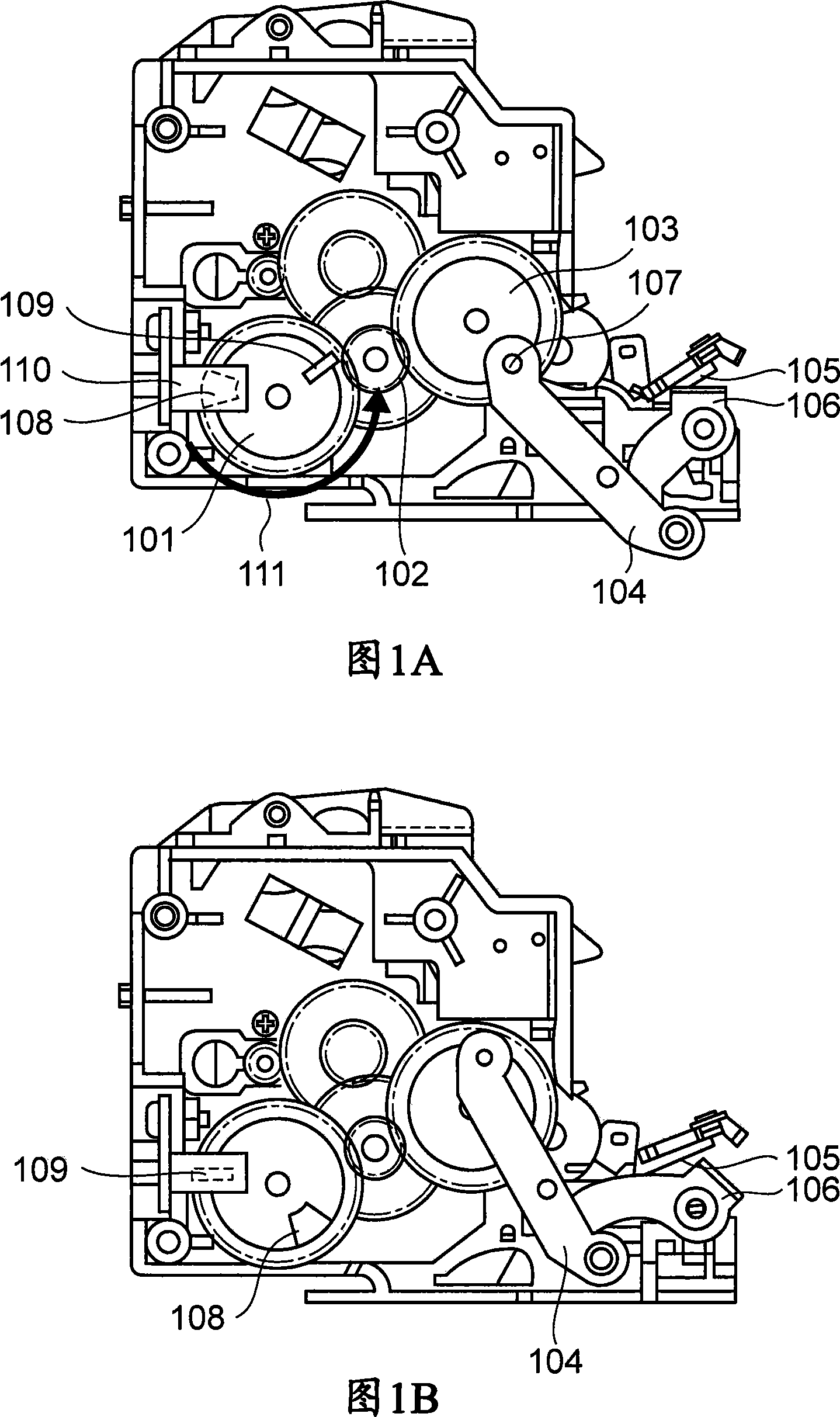

[0027] FIG. 1A is a diagram showing a structural example including a cutting device according to a first embodiment of the present invention.

[0028] The continuous paper cutting apparatus according to the first embodiment of the present invention includes: a position detection gear 101 having two or more slits having different widths in the direction of rotation of the gear 101, and the gear is rotatable to detect paper cutting The position of the machine; the gear 102, to decelerate and transmit the rotation of the position detection gear in the opposite direction of rotation; the paper cutter drive gear 103, to rotate through the gear 102; the paper cutter drive arm 104, one end of which is connected to the A paper cutter driving gear 103, so that the paper cutter driving arm 104 is rotatable, thereby driving the paper cutter; a movable blade 106 is rotatably connected to the paper cutter driving arm 104, and is reciprocally driven by the paper cutter driving arm 104; fixed...

no. 2 example

[0083] In the continuous sheet cutting apparatus according to the second embodiment of the present invention, a stepping motor is employed as a cutter motor, specifically, as a drive motor for driving the position detection gear 101 .

[0084] Except for the position detection gear 101, the structure of the second embodiment is the same as that of the first embodiment.

[0085] In the position detection gear 101 of the second embodiment, the number of initial position detection slits (ie, slits 108 ) is at least one. The continuous sheet cutting apparatus according to the second embodiment determines the cutting end position by counting the number of steps for driving the stepping motor.

[0086] Fig. 9 is a flowchart showing cutter position initialization processing performed by the continuous paper cutting apparatus of the second embodiment. In order to control the cutter position and the continuous sheet position, the present invention executes a process of bringing the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com