Multi-speed transmission

A multi-speed transmission and clutch technology, applied in vehicle gearboxes, multi-ratio transmissions, transmissions, etc., to achieve the effects of small size, reduced loss, and improved overall support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

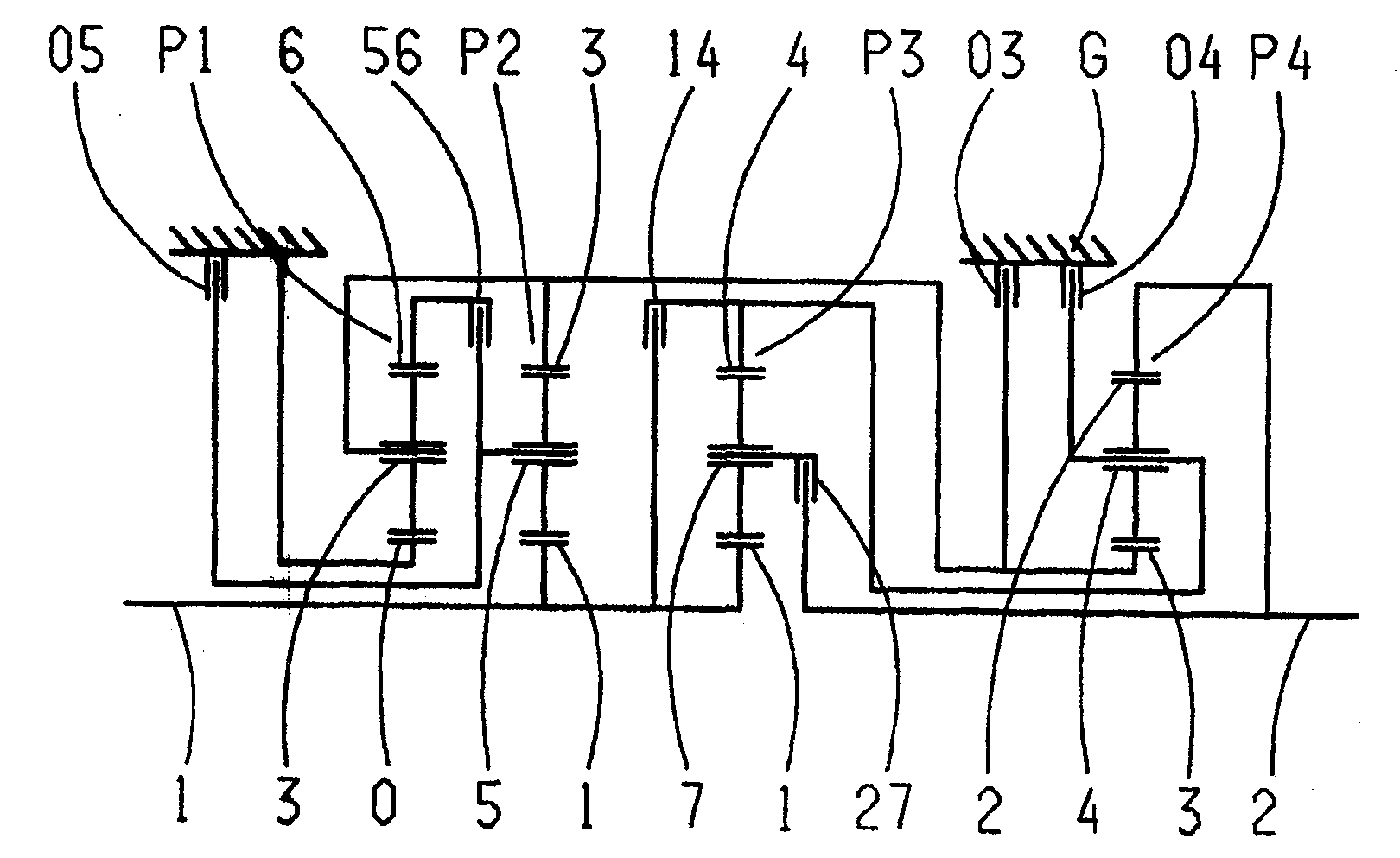

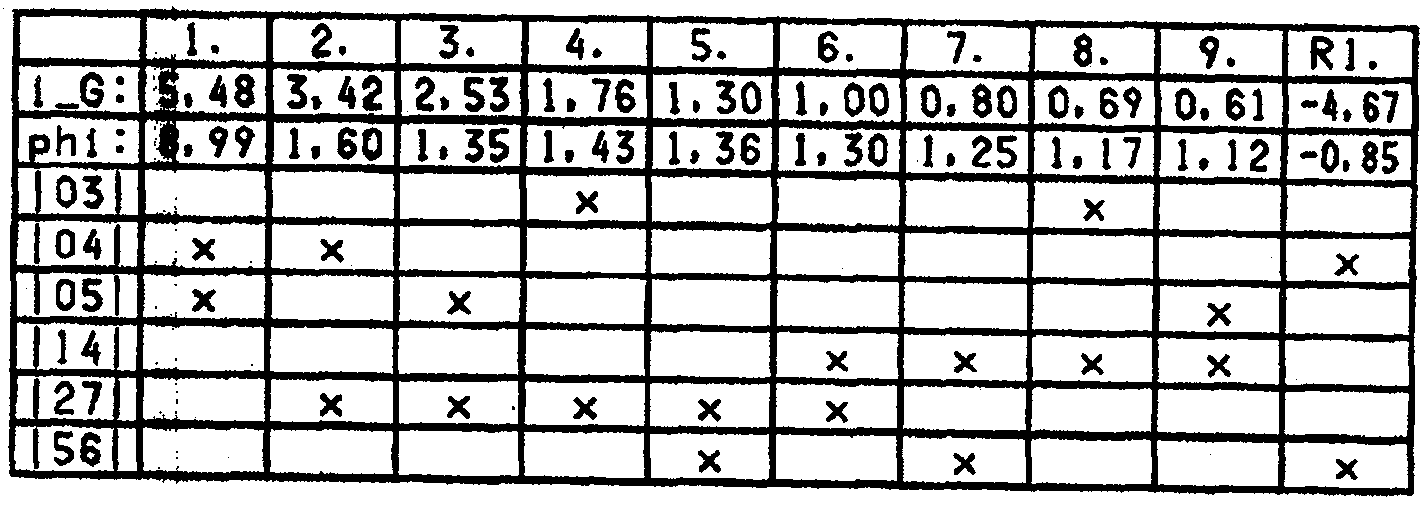

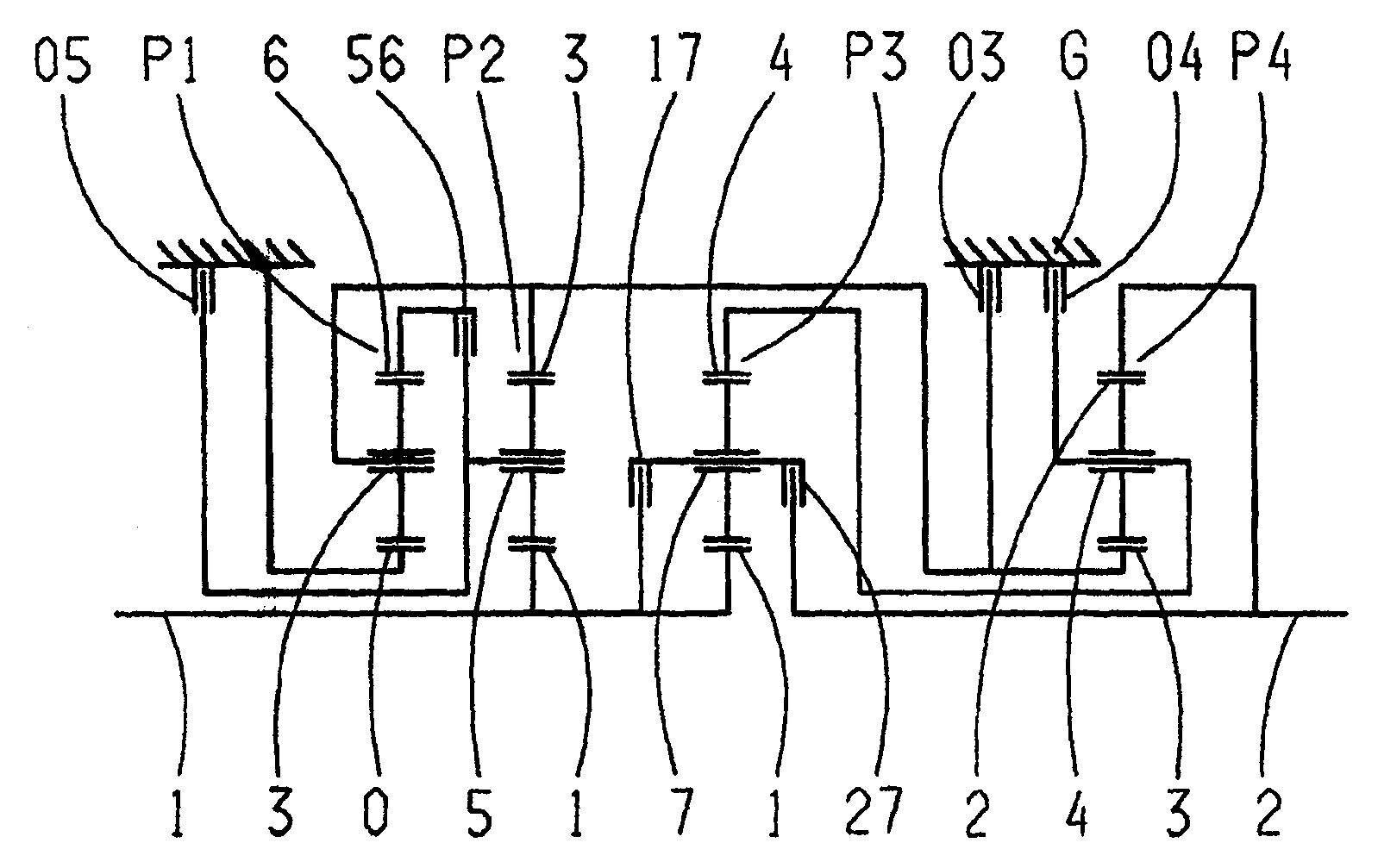

[0029] figure 1 A multi-speed transmission according to the invention is shown in , with an input shaft 1 and an output shaft 2 , which are arranged in a housing G. There are four planetary gear sets P1 , P2 , P3 and P4 which are configured as negative planetary gear sets and are preferably arranged one behind the other in the order of P1 , P2 , P3 and P4 in the axial or power flow direction.

[0030] Such as figure 1 As shown, six shifting elements are provided, ie three brakes 03 , 04 , 05 and three clutches 15 , 27 , 36 . These clutches are preferably designed as multi-disk clutches.

[0031] Using these shifting elements, it is possible to selectively switch between 9 forward gears and 1 reverse gear. The multi-speed transmission according to the invention has a total of seven rotatable shafts, namely shafts 1, 2, 3, 4, 5, 6 and 7.

[0032] According to the present invention, in figure 1 In the multi-speed transmission of the multi-speed transmission, the drive is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com