Multi-shifting speed variator

A multi-speed transmission, automatic transmission technology, applied in the direction of vehicle gearbox, multi-gear ratio transmission, transmission, etc., to achieve good efficiency, reduce loss, and small torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

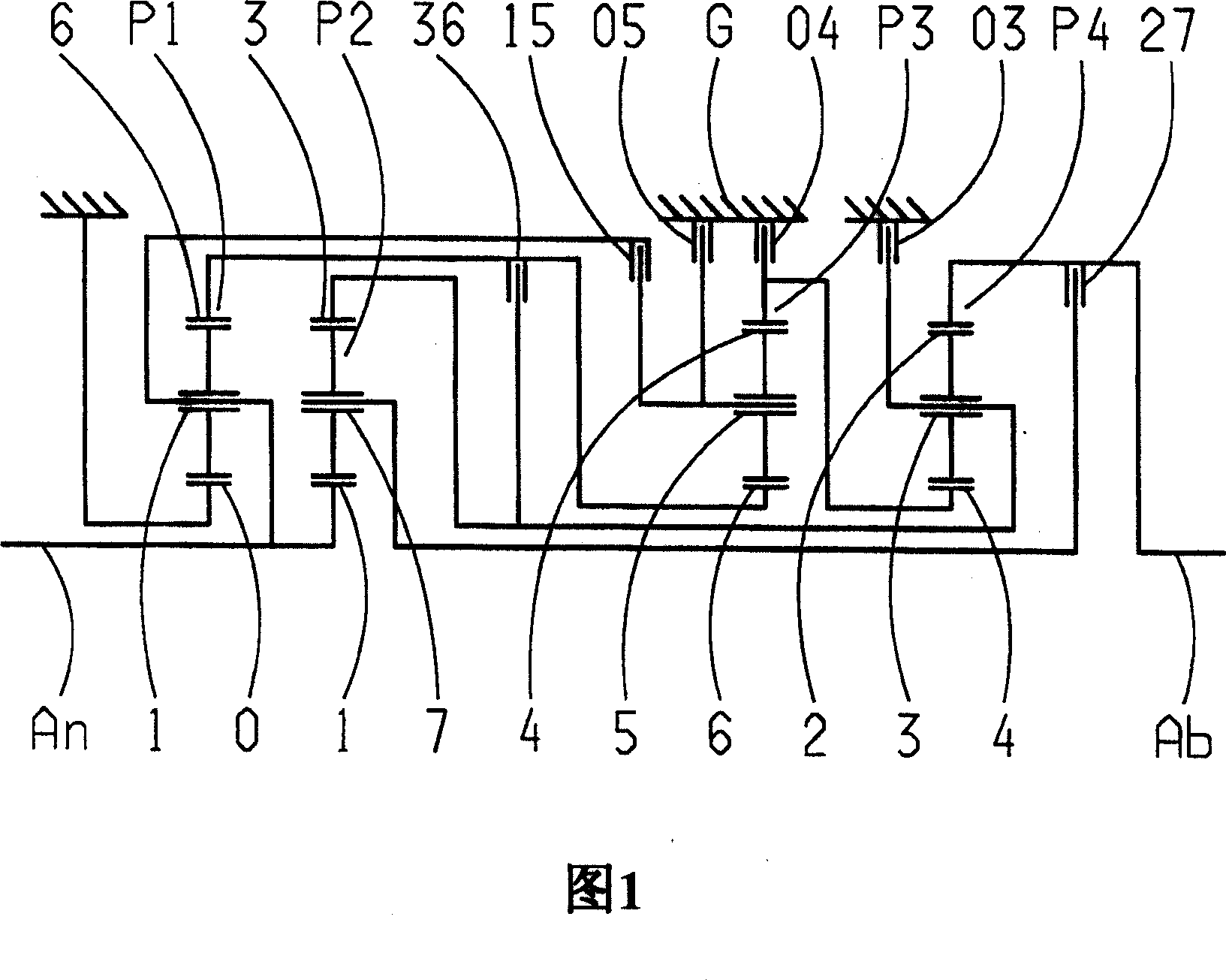

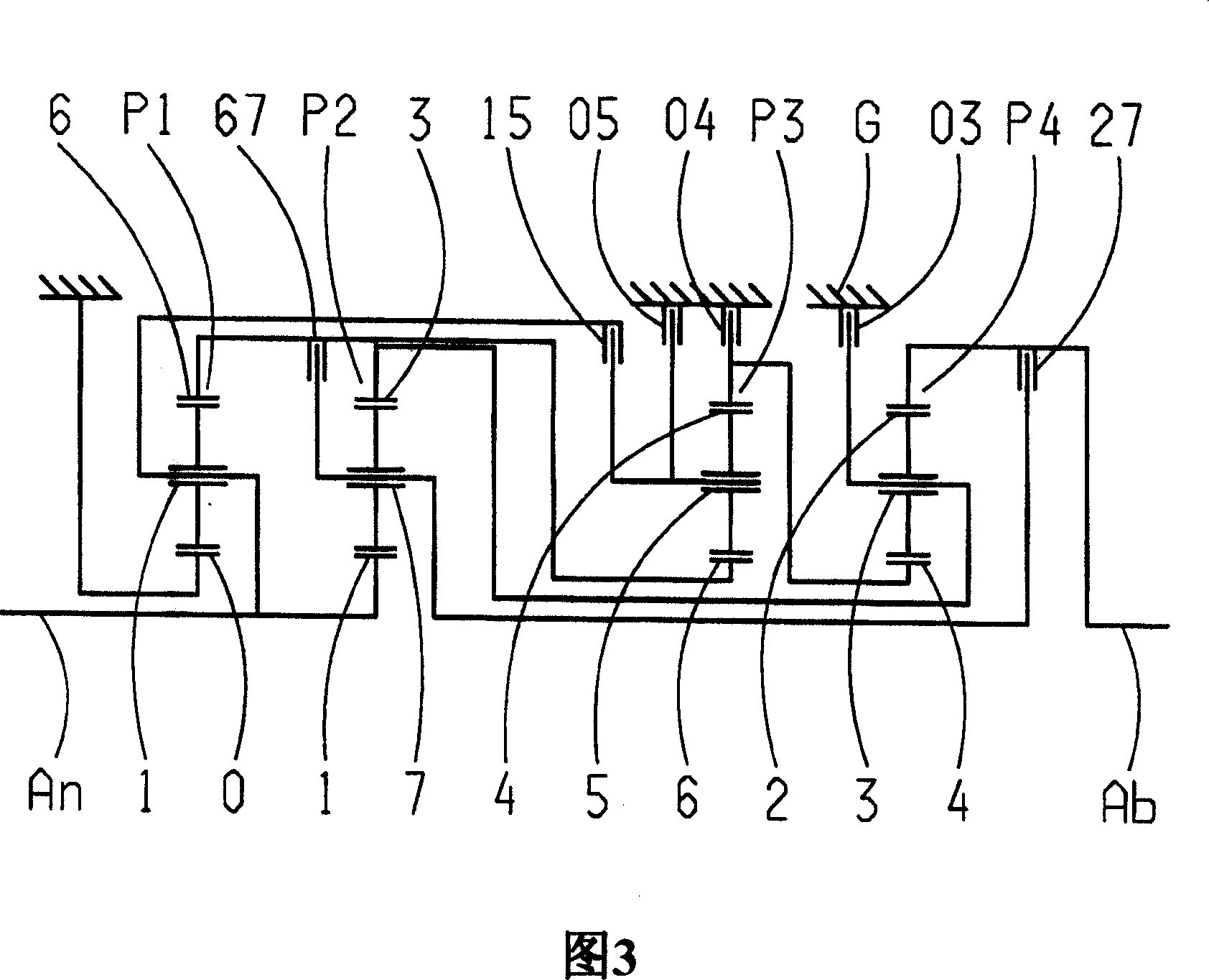

[0027] FIG. 1 shows a multi-speed transmission according to the invention with an input shaft 1 and an output shaft 2 which are arranged in a housing G. In FIG. Four planetary gearsets P1 , P2 , P3 and P4 are provided, which are configured as negative planetary gearsets and are preferably consecutive in the axial or power flow direction in the sequence of P1 , P2 , P3 and P4 .

[0028] As shown in FIG. 1 , six shifting elements are provided, ie three brakes 03 , 04 , 05 and three clutches 15 , 27 , 36 . These clutches are preferably designed as multi-disk clutches.

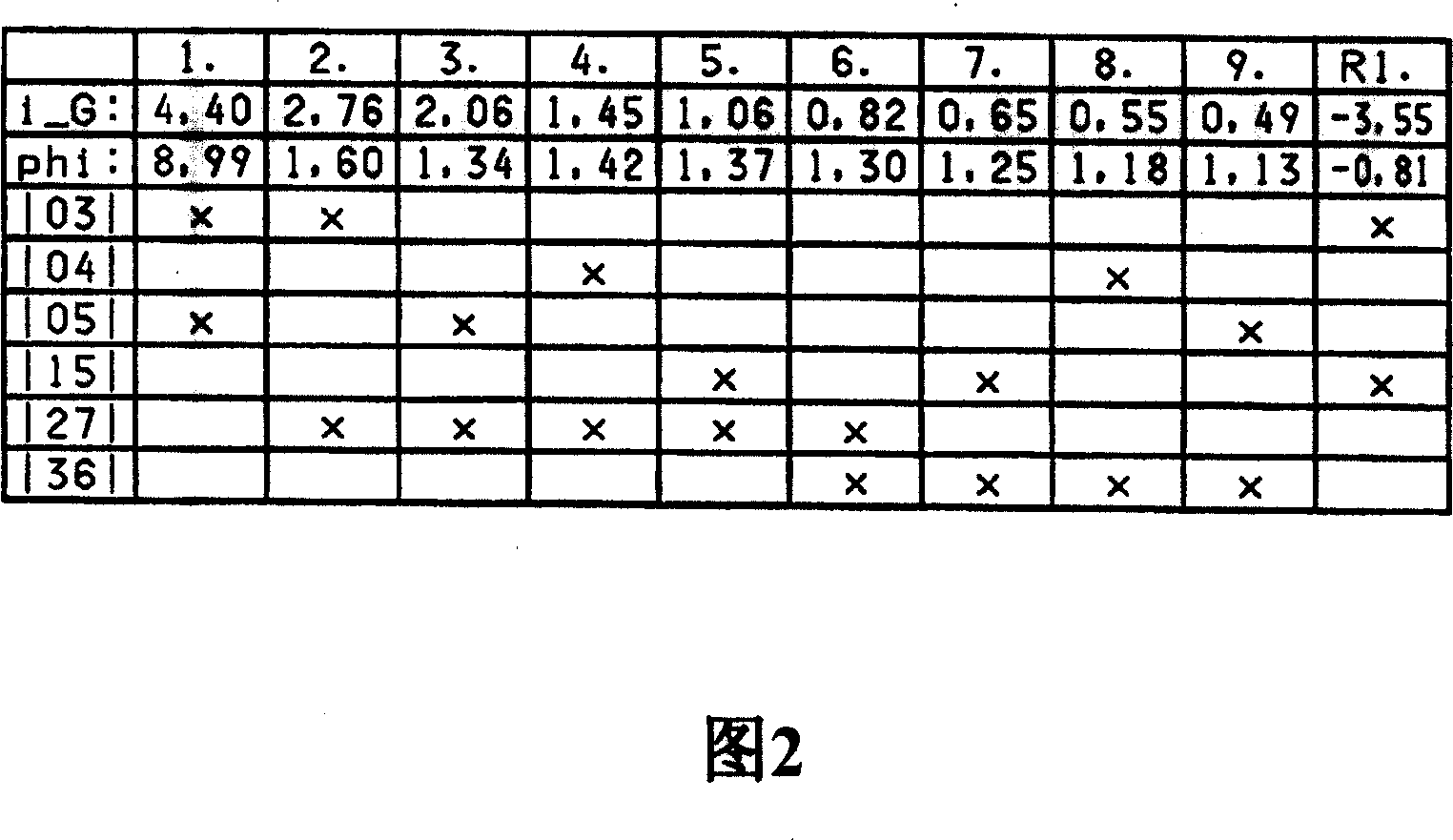

[0029] Using these shifting elements, it is possible to selectively switch between 9 forward gears and 1 reverse gear. The multi-speed transmission according to the invention has a total of seven rotatable shafts, namely shafts 1 , 2 , 3 , 4 , 5 , 6 and 7 .

[0030] According to the invention, in the multi-speed transmission of FIG. 1 it is provided that the drive is performed via shaft 1, which is permanently c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com