Magnetic induction ruler reading head calibration device

A magnetic induction and correction device technology, which is applied in the direction of measuring devices, measuring magnetic variables, and the size/direction of the magnetic field, can solve problems such as difficult to measure correctly, increased additional costs, and long installation time intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

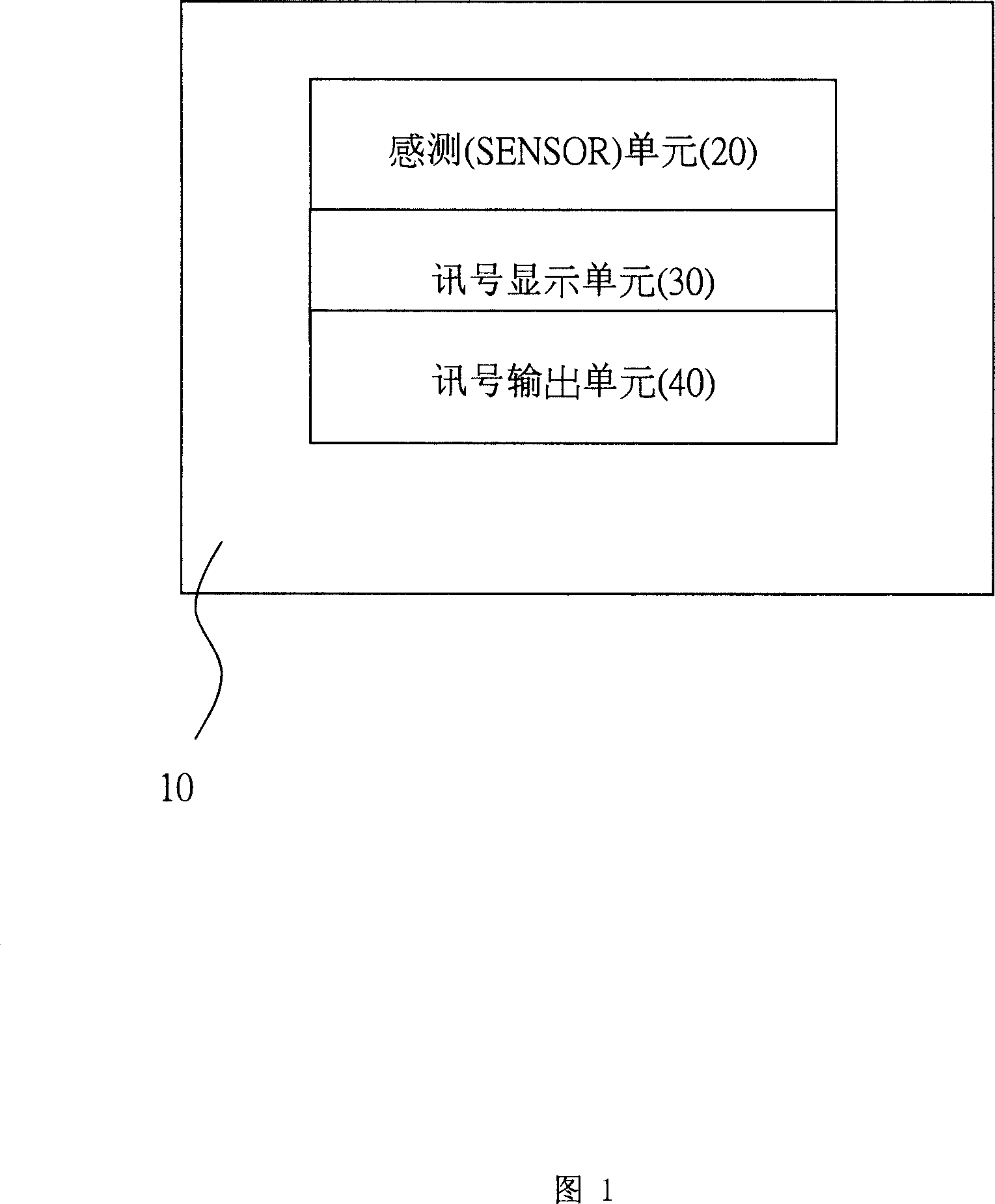

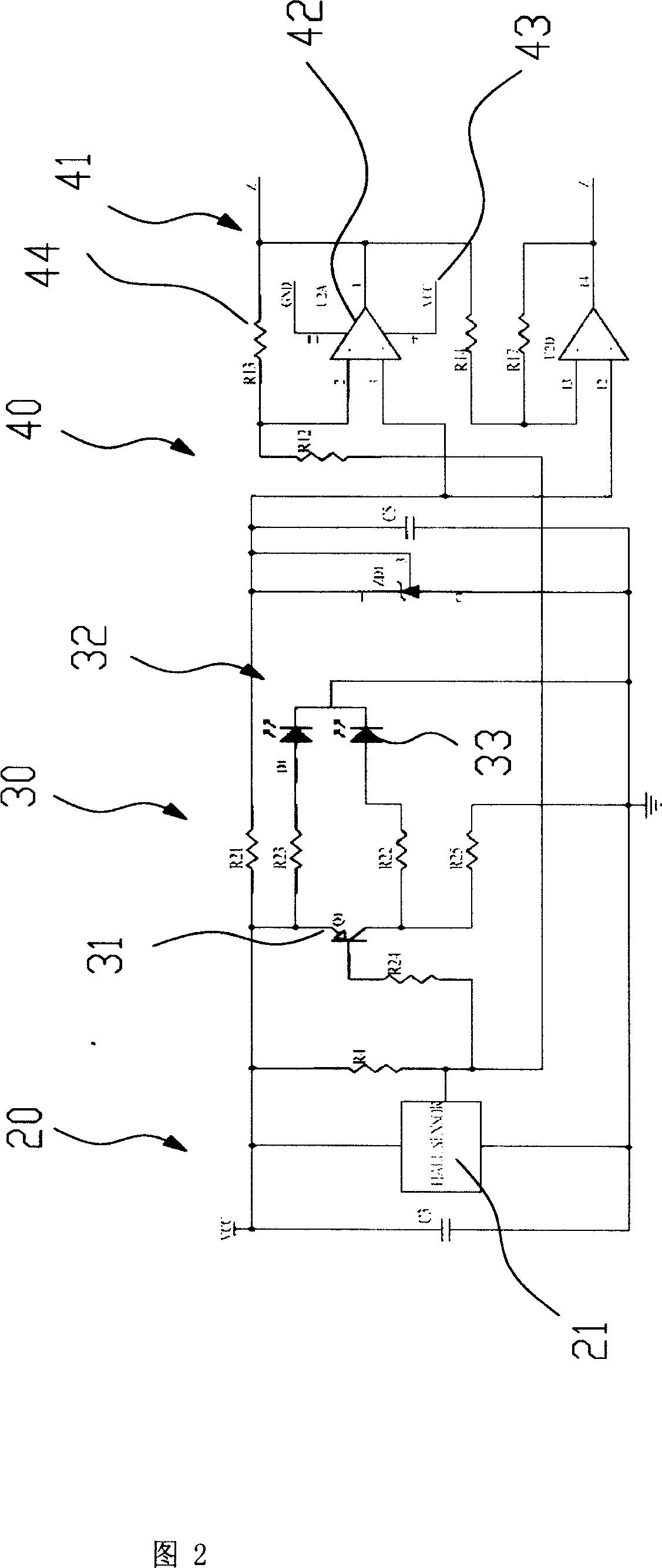

[0040] Please refer to Fig. 1 and shown in Fig. 2, the present invention is a kind of magnetic induction scale induction read head correction device, described induction read head 10 mainly comprises:

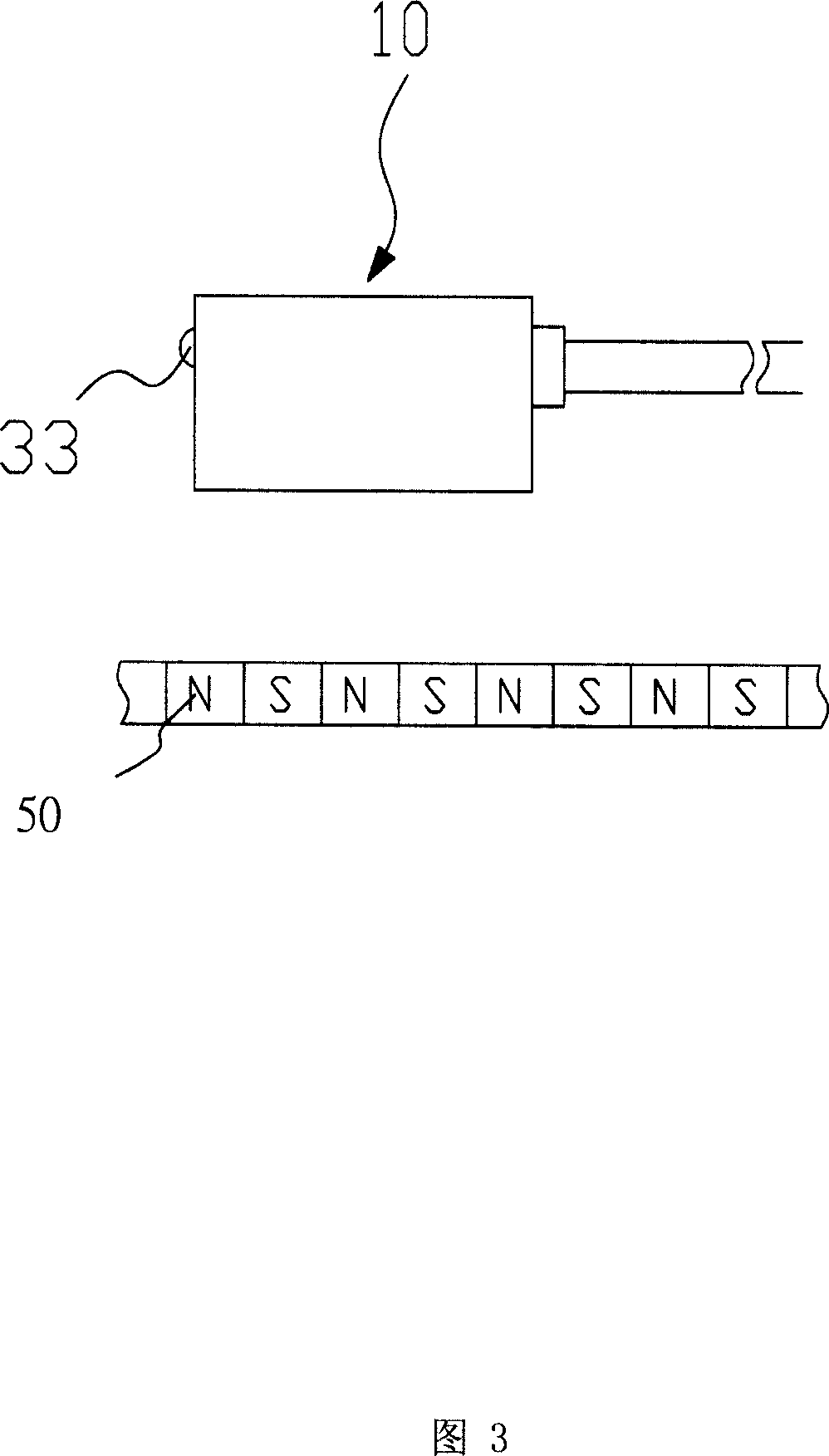

[0041] A sensing (SENSOR) unit 20, which includes a Hall sensor (HALL SENSOR) 21, said Hall sensor (HALL SENSOR) 21 can use the generation of the Hall effect to sense the change of the magnetic field, and output a square wave signal Wherein, when the Hall sensor (HALL SENSOR) 21 senses the N-pole magnetic field, the sensing (SENSOR) unit 20 outputs a high (Hi) signal, and when the Hall sensor (HALL SENSOR) 21 senses When the S pole magnetic field is reached, the sensing (SENSOR) unit 20 outputs a Low signal.

[0042] A signal display unit 30, which includes an amplifying transistor 31, the amplifying transistor 31 can output the signal of the sensing (SENSOR) unit 20 to a display component 32, and drive the display component 32 to change, To display the signal state of the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com