Light guiding member and light guiding plate using the same

A technology of light guide and light guide plate, applied in the field of light guide plate

Active Publication Date: 2010-11-24

LITE ON OPTO TECH (CHANGZHOU) CO LTD +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, the side part of the package in the non-light-emitting area may also leak light to reduce the amount of light received by the light-incident surface R1

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 example

no. 2 example

no. 3 example

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Login to View More

Abstract

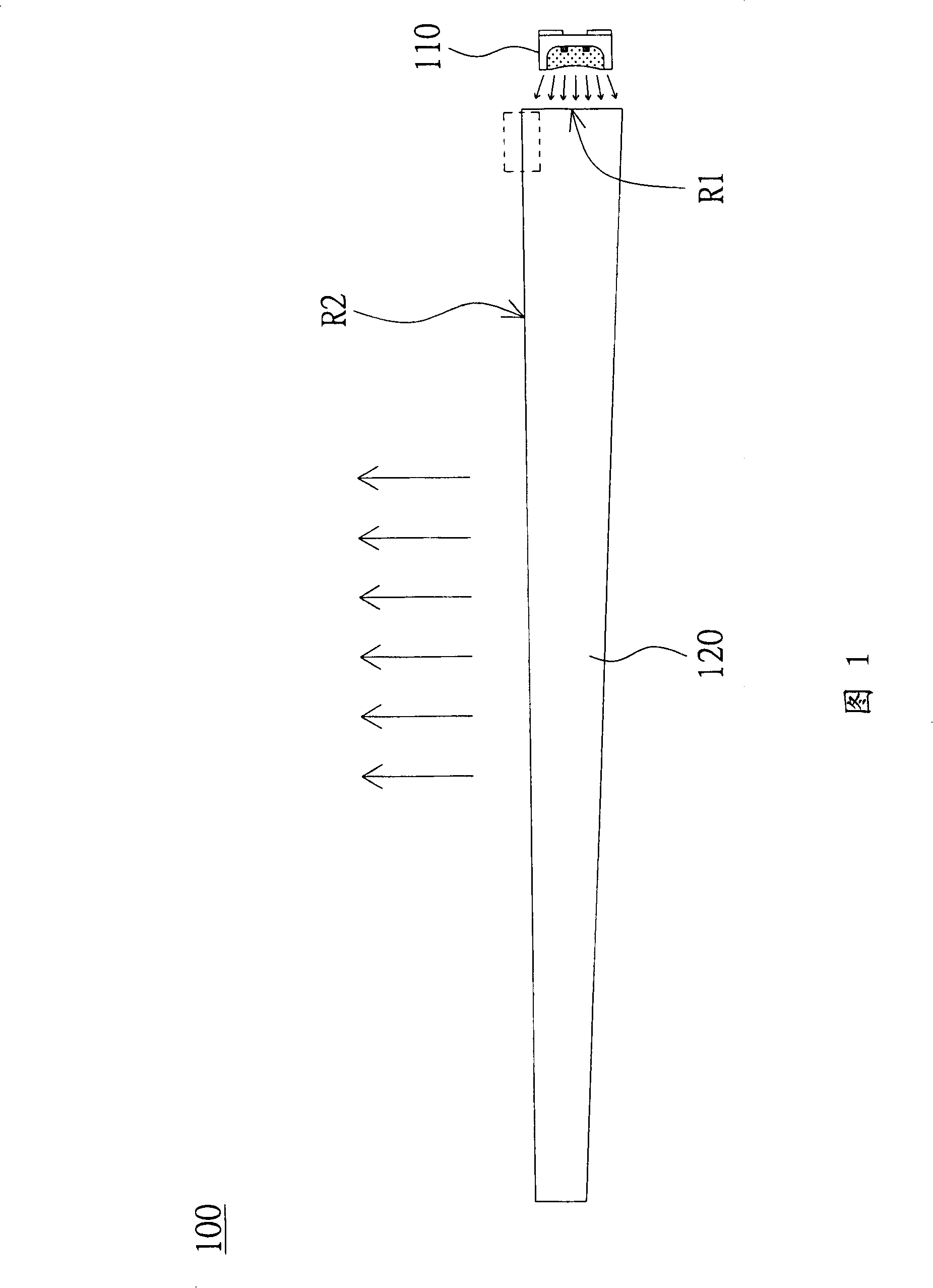

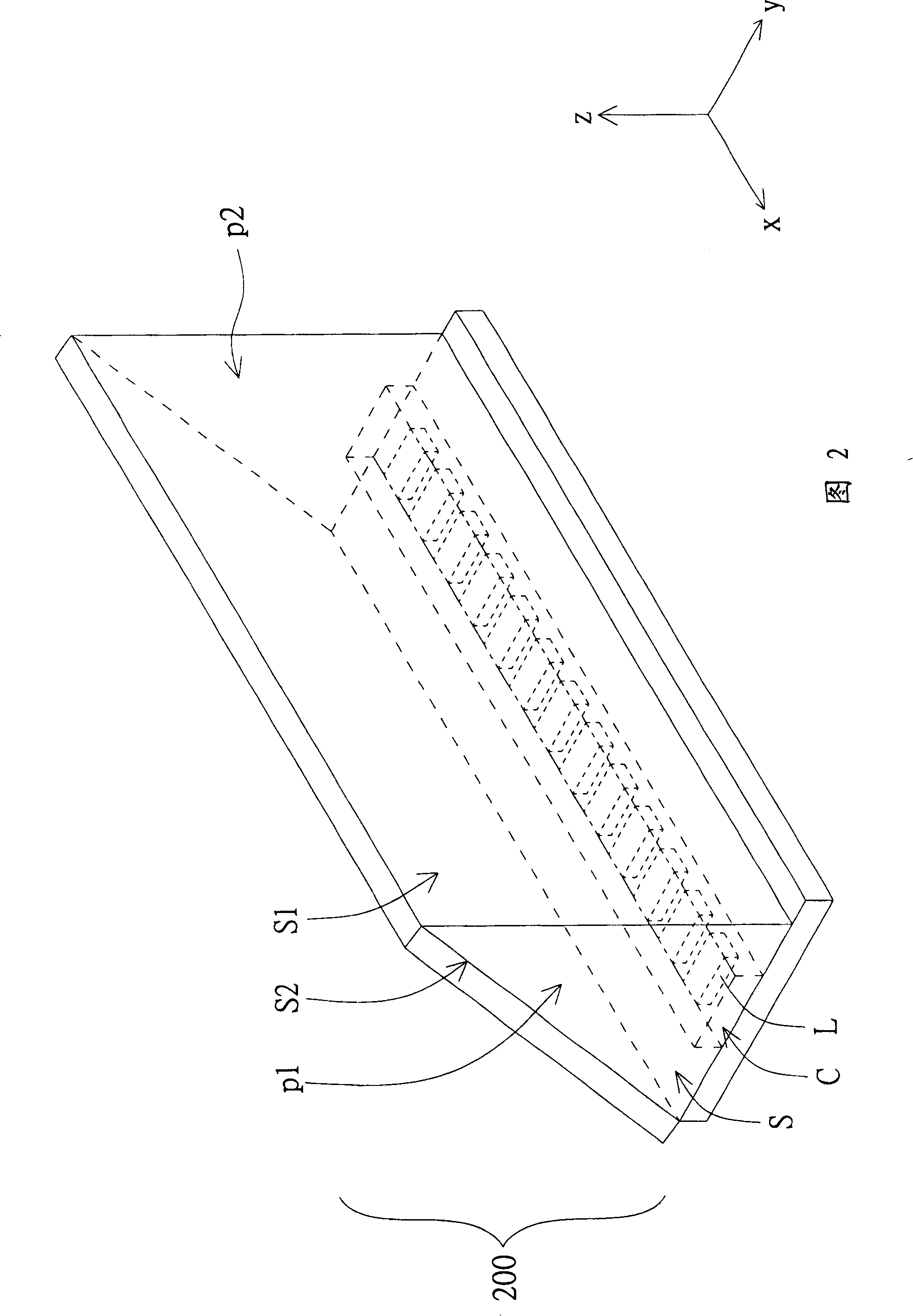

The present invention discloses a light-conducting piece which is provided with a first surface, a second surface and a bottom surface. The bottom surface, the first surface and the second surface limit the inner side of the light-conducting piece. The bottom surface is provided with a groove in order that light emits from the inner side of the light-conducting piece via the first surface when the light source lies in the groove and produces light.

Description

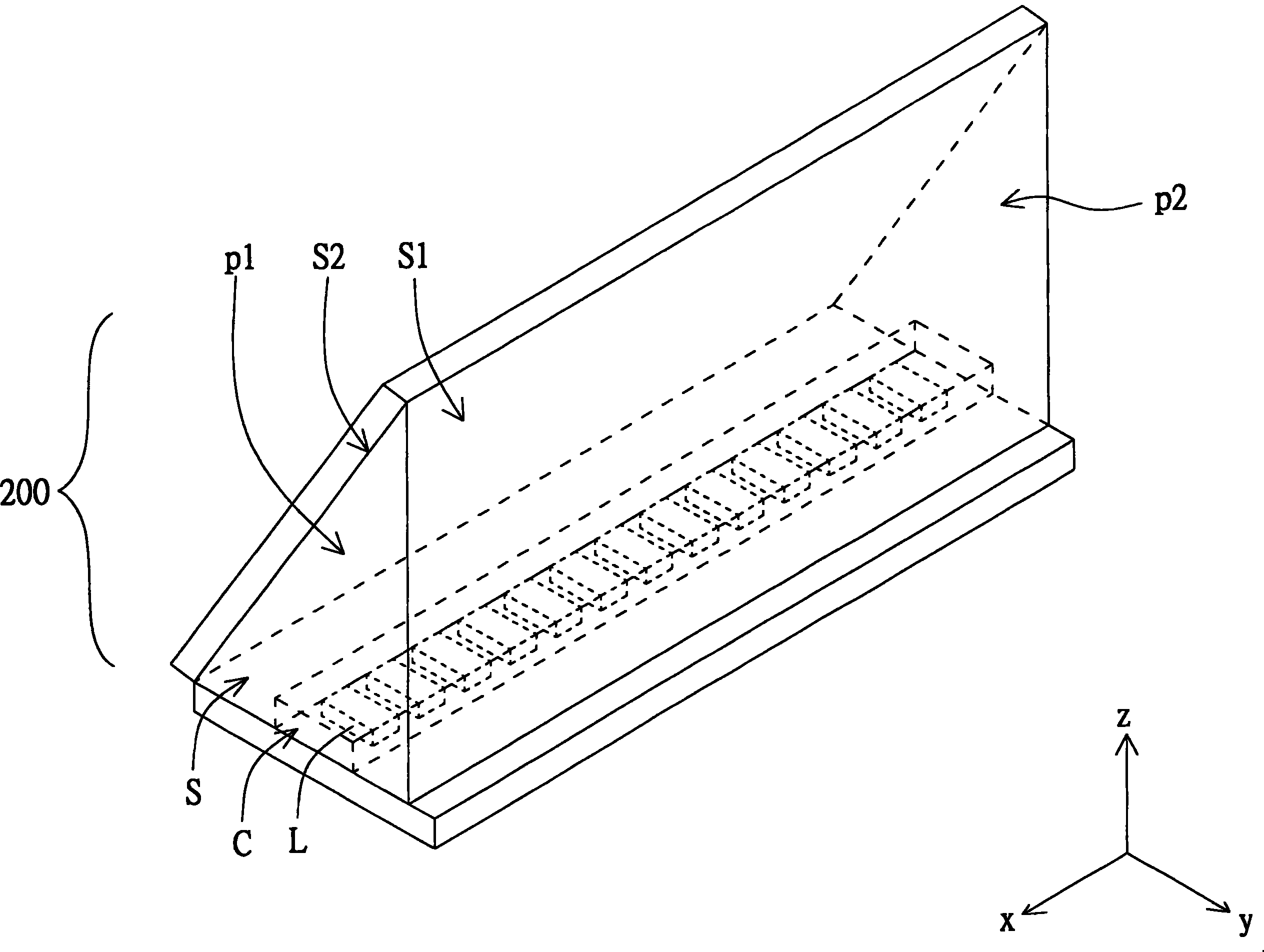

Light guide and light guide plate using the light guide technical field The invention relates to the field of light guide technology, in particular to a light guide member capable of increasing light utilization and a light guide plate using the same. Background technique Please refer to FIG. 1 , which shows a partial structure diagram of a conventional backlight module. The backlight module 100 is, for example, an edge-lit backlight module, and includes a light source 110 and a light guide plate 120 . The light guide plate 120 is generally a wedge-shaped plate or a flat plate, and has a light incident surface R1 and a light exit surface R2. The light source 110 is, for example, a light emitting diode (Light Emitting Diode, LED) light bar, and is disposed adjacent to the light incident surface R1. The light source 110 is used to generate light, and enter the light guide plate 120 through the light incident surface R1 , and then guide the light to the light exit surface R...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G02B6/00G02B1/04G02B6/122

Inventor 刘育男王慈维

Owner LITE ON OPTO TECH (CHANGZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com