Light guiding member and light guiding plate using the same

A technology of light guide and light guide plate, applied in the field of light guide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

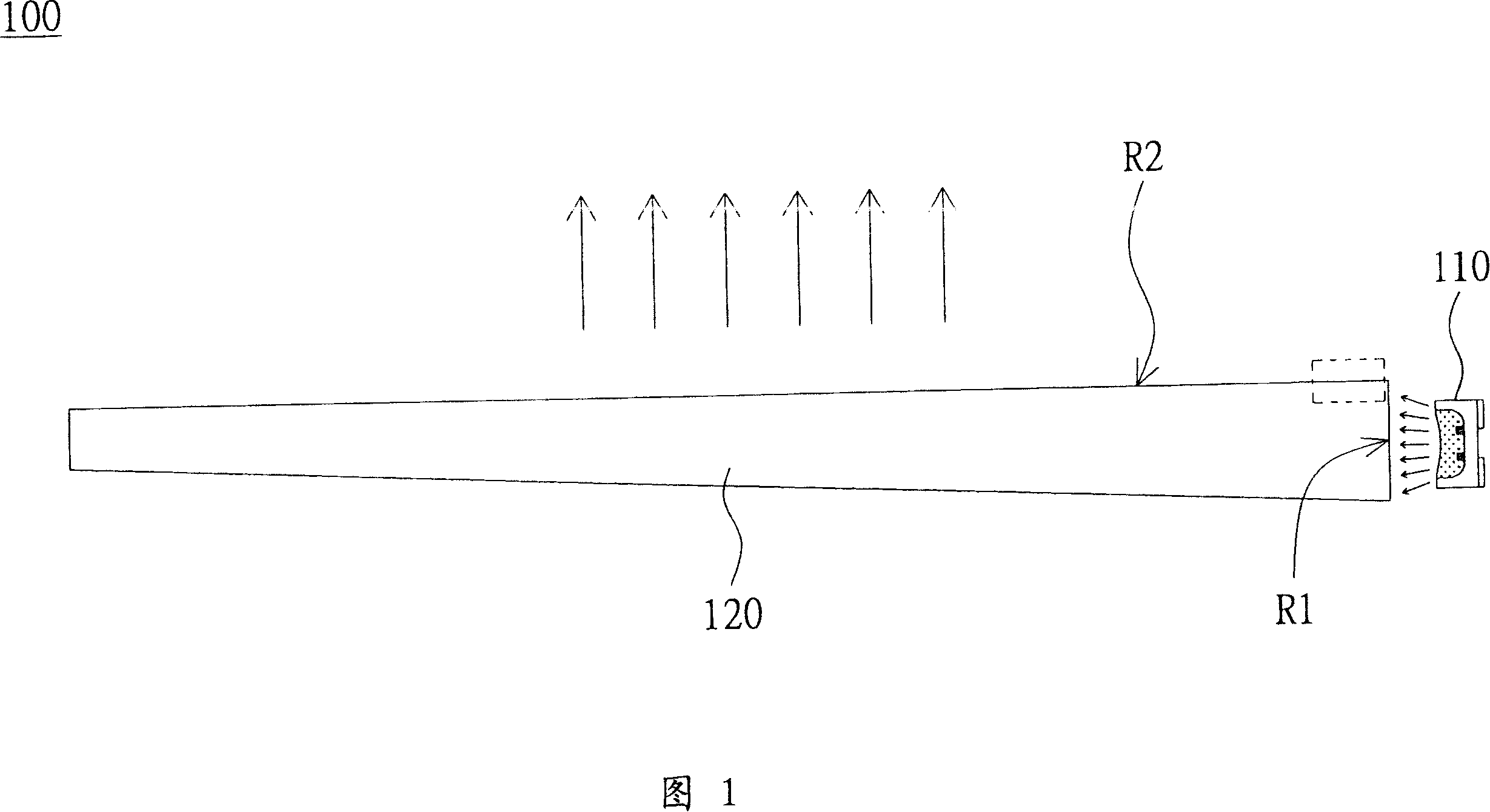

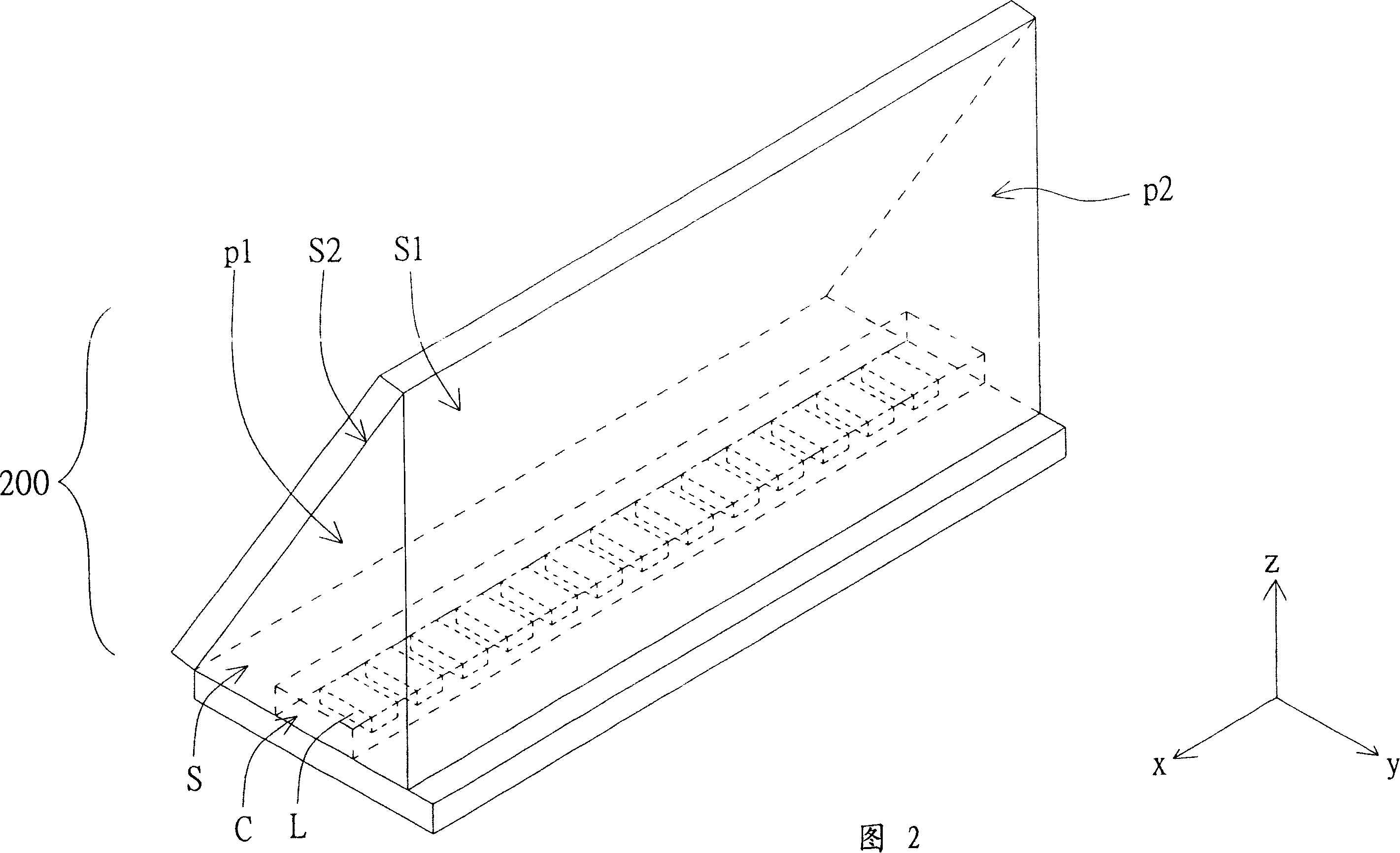

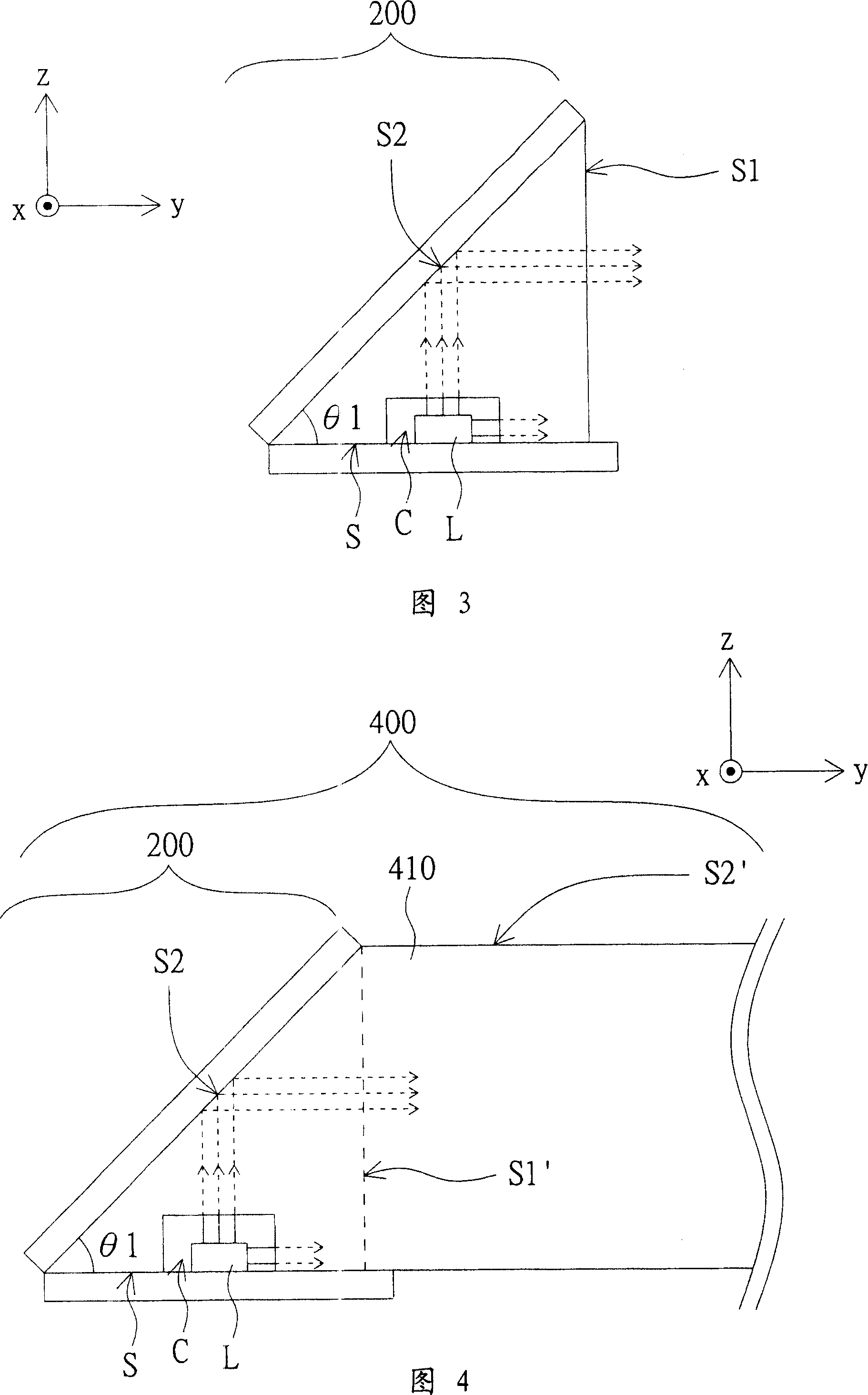

[0030] Please refer to FIG. 2, which illustrates a schematic diagram of the light guide according to the first embodiment of the present invention when a light source is embedded. In the first embodiment, the light guide 200 is substantially a column (a triangular column as shown in FIG. 2), and has a first surface S1 (parallel xz plane), a second surface S2, and a bottom surface S (parallel xy plane). ) And the two side faces p1 and p2 (parallel yz plane) intersecting the above three faces. The first surface S1, the second surface S2, and the bottom surface S are adjacent to each other in pairs, and jointly define the interior of the light guide 200, that is, the volume range surrounded by the three surfaces.

[0031] In addition, the bottom surface S has a groove C for accommodating the light source L. In the first embodiment, the light source L is a light emitting diode (Light Emitting Diode, LED) group as an example for illustration, that is, LED packages arranged side by side...

no. 2 example

[0035] Please refer to FIG. 5, which illustrates a side view of the light guide according to the second embodiment of the present invention when a light source is embedded. The second embodiment is different from the first embodiment in that the second surface T2 of the light guide 500 further has a V-cut structure. And preferably, the cut surface of each V-shaped groove is 45 degrees with the bottom surface. As a result, the second surface T2 achieves the same reflection effect as the first embodiment with the cut surface of the groove, and the acute angle θ2 between the second surface T2 and the bottom surface T can have greater adjustment flexibility. For example, θ2 can be 30 degrees. The height of the first surface T1 is smaller than the first surface S1 of FIG. 3. When applied to the light guide plate, the thickness of the body of the light guide plate can be effectively reduced, making the backlight module and the display lighter and thinner.

no. 3 example

[0037] Please refer to FIG. 6, which illustrates a side view of the light guide according to the third embodiment of the present invention when a light source is embedded. In the third embodiment, the second surface U2 of the light guide 600 is an arc surface. The curvature of the arc can also be adjusted depending on the type of light source L or the preset height of the first surface U1, for example, it is a part of an arc or a cast surface. Fig. 6 takes the arc as an example. Of course, a suitable V-shaped prism structure can also be added to part of the second surface U2 as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com