Bulletproof steel plate as well as preparation method and application thereof

A steel plate and molten steel technology, which is applied in the field of bulletproof steel plate and its preparation, can solve the problems of low deformation resistance and insufficient lightness of the steel plate, and achieve the effects of refining grains, ensuring high strength, and ensuring low deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

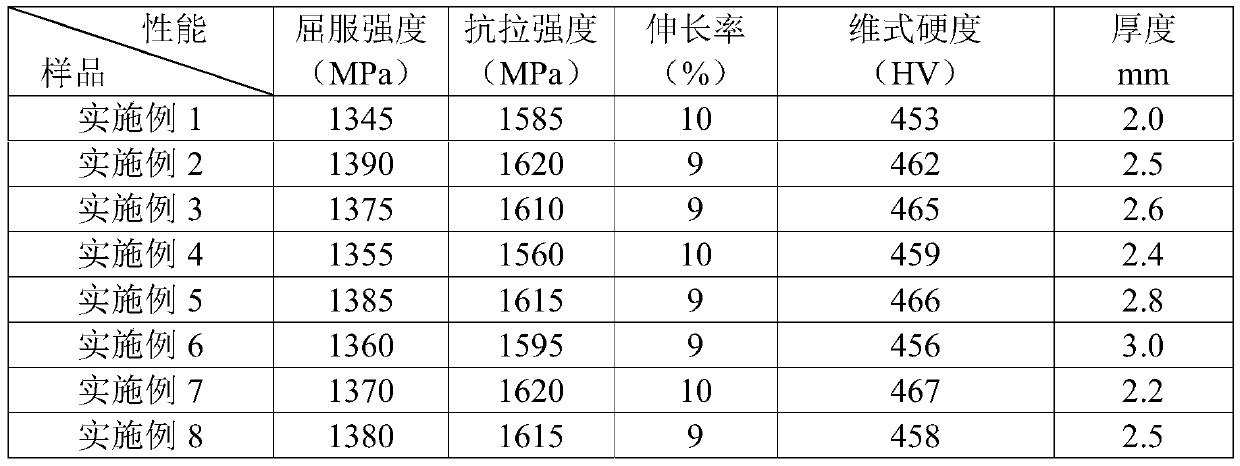

Examples

Embodiment 1

[0096] This embodiment provides a bulletproof steel plate, which includes the following components in terms of mass percentage: C: 0.26%, Si: 0.20%, Mn: 0.75%, P: 0.009%, S: 0.003%, Ni : 1.05%, Cr: 0.75%, Mo: 0.25%, V: 0.085%, Als: 0.020%, N: 0.0020%, and the balance is Fe and inevitable impurity elements.

[0097] The preparation method of the bulletproof steel plate provided by this embodiment comprises the following steps:

[0098] (1) smelting the raw material components into molten steel, and the molten steel obtains slab through molten steel desulfurization, converter smelting, ladle refining, RH vacuum cycle degassing refining and continuous casting operations;

[0099] (2) The slab is heated to 1220°C, descaled by 18MPa high-pressure water, and then subjected to 5 passes of rough rolling, and the outlet temperature is 1120°C. Rolling, the inlet temperature of finish rolling is 1040°C, and the outlet temperature is 880°C. After the finish rolling, the laminar cooling r...

Embodiment 2

[0102] This embodiment provides a bulletproof steel plate, which includes the following components in terms of mass percentage: C: 0.31%, Si: 0.40%, Mn: 1.10%, P: 0.010%, S: 0.003%, Ni : 1.30%, Cr: 1.10%, Mo: 0.45%, V: 0.105%, Als: 0.060%, N: 0.0030%, and the balance is Fe and unavoidable impurity elements.

[0103] The preparation method of the bulletproof steel plate provided by this embodiment comprises the following steps:

[0104] (1) smelting the raw material components into molten steel, and the molten steel obtains slab through molten steel desulfurization, converter smelting, ladle refining, RH vacuum cycle degassing refining and continuous casting operations;

[0105] (2) The slab is heated to 1260°C, descaled by 18MPa high-pressure water, and then subjected to 5 passes of rough rolling, and the outlet temperature is 1160°C. Rolling, the inlet temperature of finish rolling is 1080°C, and the outlet temperature is 920°C. After the finish rolling, the laminar cooling ...

Embodiment 3

[0108] This embodiment provides a bulletproof steel plate, which includes the following components in terms of mass percentage: C: 0.30%, Si: 0.30%, Mn: 0.90%, P: 0.008%, S: 0.002%, Ni : 1.20%, Cr: 0.95%, Mo: 0.30%, V: 0.095%, Als: 0.040%, N: 0.002%, and the balance is Fe and inevitable impurity elements.

[0109] The preparation method of the bulletproof steel plate provided by this embodiment comprises the following steps:

[0110] (1) smelting the raw material components into molten steel, and the molten steel obtains slab through molten steel desulfurization, converter smelting, ladle refining, RH vacuum cycle degassing refining and continuous casting operations;

[0111] (2) The slab is heated to 1242°C, descaled by 18MPa high-pressure water, and then subjected to 5 passes of rough rolling, the outlet temperature is 1144°C, and 7-stand rolling mills are used for finishing rolling after coiling by the hot coil box. Rolling, the inlet temperature of finish rolling is 1063°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com